Preparation method for chicken protein enzymolysis liquid and prepared chicken protein enzymolysis liquid

A technology of proteolysis solution and protease, which is applied in food preparation, application, food science, etc., can solve the problems of monotonous taste and loss of chicken nutrients, etc., and achieve the effect of facilitating human body absorption, enriching taste, and pure flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: comparative test of the degree of hydrolysis of protein

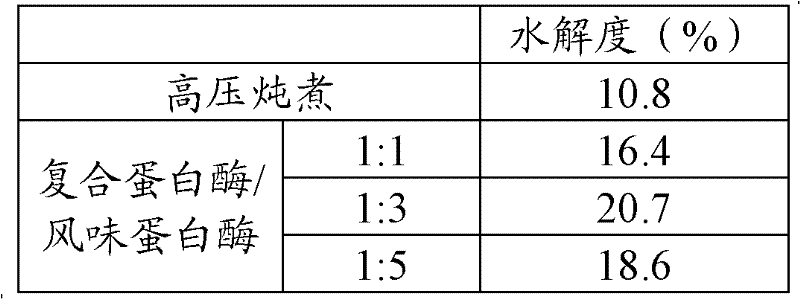

[0024] In the test, a mixed enzyme composed of compound protease and flavor protease was selected for enzymolysis under suitable conditions. Compared with the high-pressure stewing method, the degree of protein hydrolysis was analyzed. The results are shown in Table 1.

[0025] The invention adopts the formaldehyde titration method to measure the degree of hydrolysis of the protein. Calculated as follows:

[0026] Degree of hydrolysis (%)=(content of free ammoniacal nitrogen in chicken broth / content of nitrogen in chicken broth)×100%

[0027] Table 1 The degree of hydrolysis of different proteases

[0028]

[0029] It can be seen from Table 1 that the degree of hydrolysis of combined protease and flavor protease is significantly greater than that of high-pressure stewing, and when the mass ratio of compound protease and flavor protease is 1:3, the degree of hydrolysis of protein is significantl...

Embodiment 2

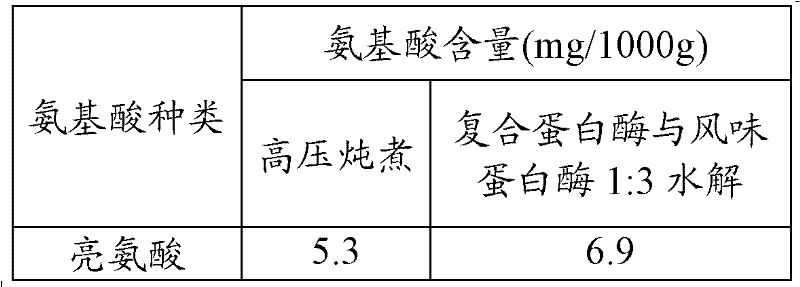

[0030] Embodiment 2: amino acid content analysis test

[0031] Take an equal amount of fresh chicken nuggets and pulverize them, add water to immerse them, and use a mixed enzyme of compound protease and flavor protease with a mass ratio of 1:3 to carry out enzymolysis under suitable conditions. Analyze the type and content of amino acids. The detection of amino acid types and content is carried out with reference to the determination standard of amino acids in food GB / T 5009.124-2003.

[0032] Table 2 Amino acid detection results

[0033]

[0034] The test results show that the content of leucine, which can improve the flavor, in the chicken protein hydrolyzate of the mixed enzyme of compound protease and flavor protease with a mass ratio of 1:3 is significantly higher than that of high-pressure stewing chicken broth, while the content of other amino acids Amounts similar to those found in pressure-cooked chicken broth. The results showed that the enzymatic hydrolysis o...

Embodiment 3

[0035] Embodiment 3: the preparation of chicken protein enzymatic hydrolyzate of the present invention

[0036] Crush the washed 100 kg fresh chicken nuggets, immerse them in water, and precook them in boiling water for about 15 minutes. Cool, adjust the pH value to 6.8-7.2, add 3 kg of flavor protease and 1 kg of compound protease, and enzymatically hydrolyze at 55°C for 3 hours. Heat the enzymolysis solution to 80°C for 20 minutes to inactivate the enzyme. Use a 100-mesh filter to filter out the bone residue, and use a high-speed centrifuge to separate the oil and impurities in the soup.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com