A double electrodeless lamp magnetic core winding process and its manufacturing method

A production method and the technology of electrodeless lamps, which are applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of slow start-up and high energy consumption, save energy and cost, and are beneficial to vision health , Start and restart performance superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

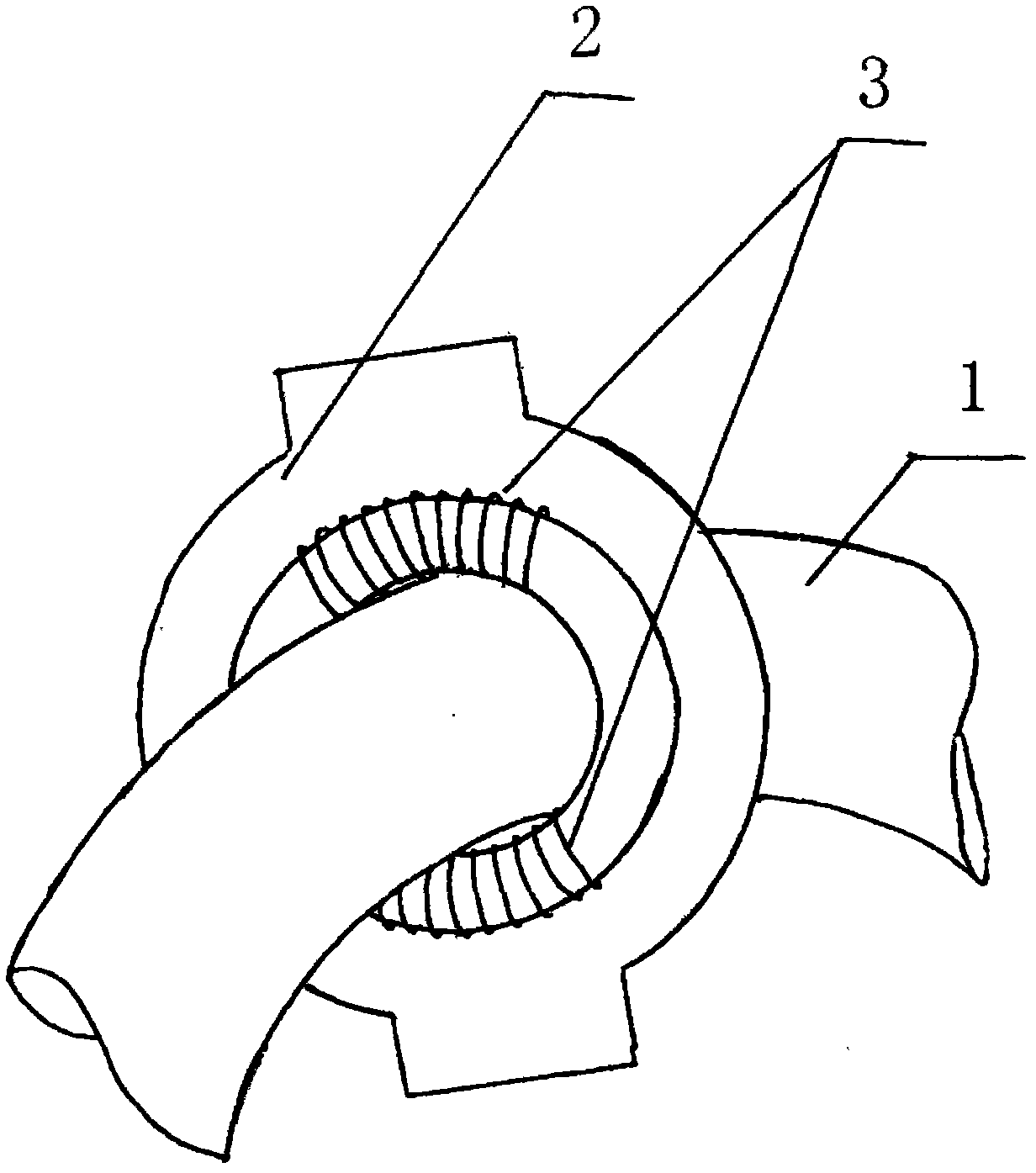

[0010] The two ends of the coupler magnetic core 2 of the electrodeless lamp 1 are wound to form the double magnetic core winding group 3 of the electrodeless lamp, so that the electromagnetic induction of the single wire group of the electrodeless lamp tube becomes the electromagnetic induction of the double wire group, and the electric energy exceeds Quickly transform into an electromagnetic field to excite the fluorescent powder to emit light; use the double-core winding process of the electrodeless lamp to make the coupler core winding 3, which can increase the energy coupled from the low-frequency generator to the device in the lamp tube through the wire group, and further shorten the start-up time .

[0011] As mentioned above, the embodiment is only a description of the preferred embodiment of the present invention, and is not intended to limit the scope of the present invention. On the premise of not departing from the spirit of the technology of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com