Aluminum flatness visual inspection system

A visual inspection and flatness technology, applied in the field of physics, can solve problems such as difficult high-speed inspection of aluminum plate flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

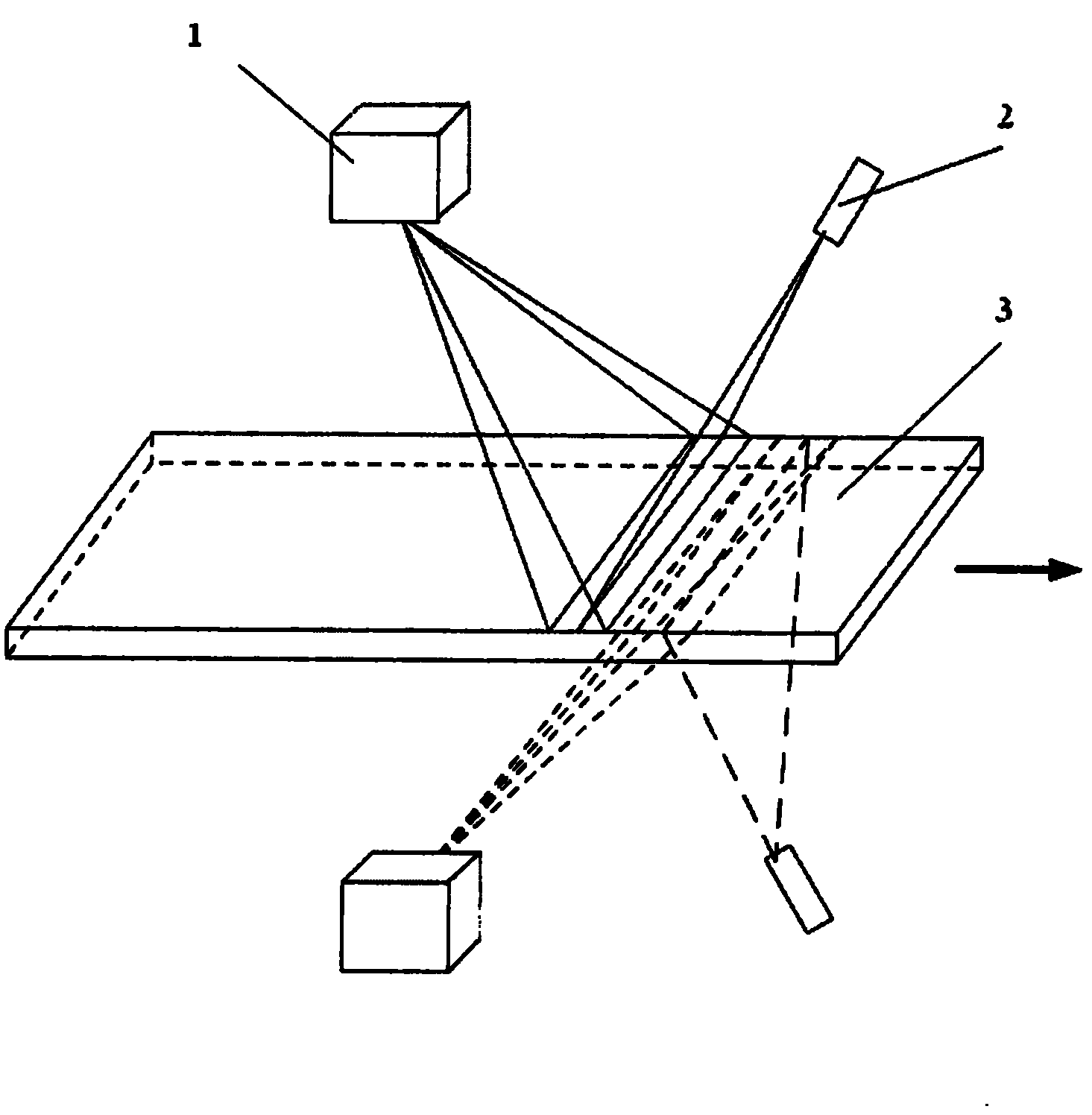

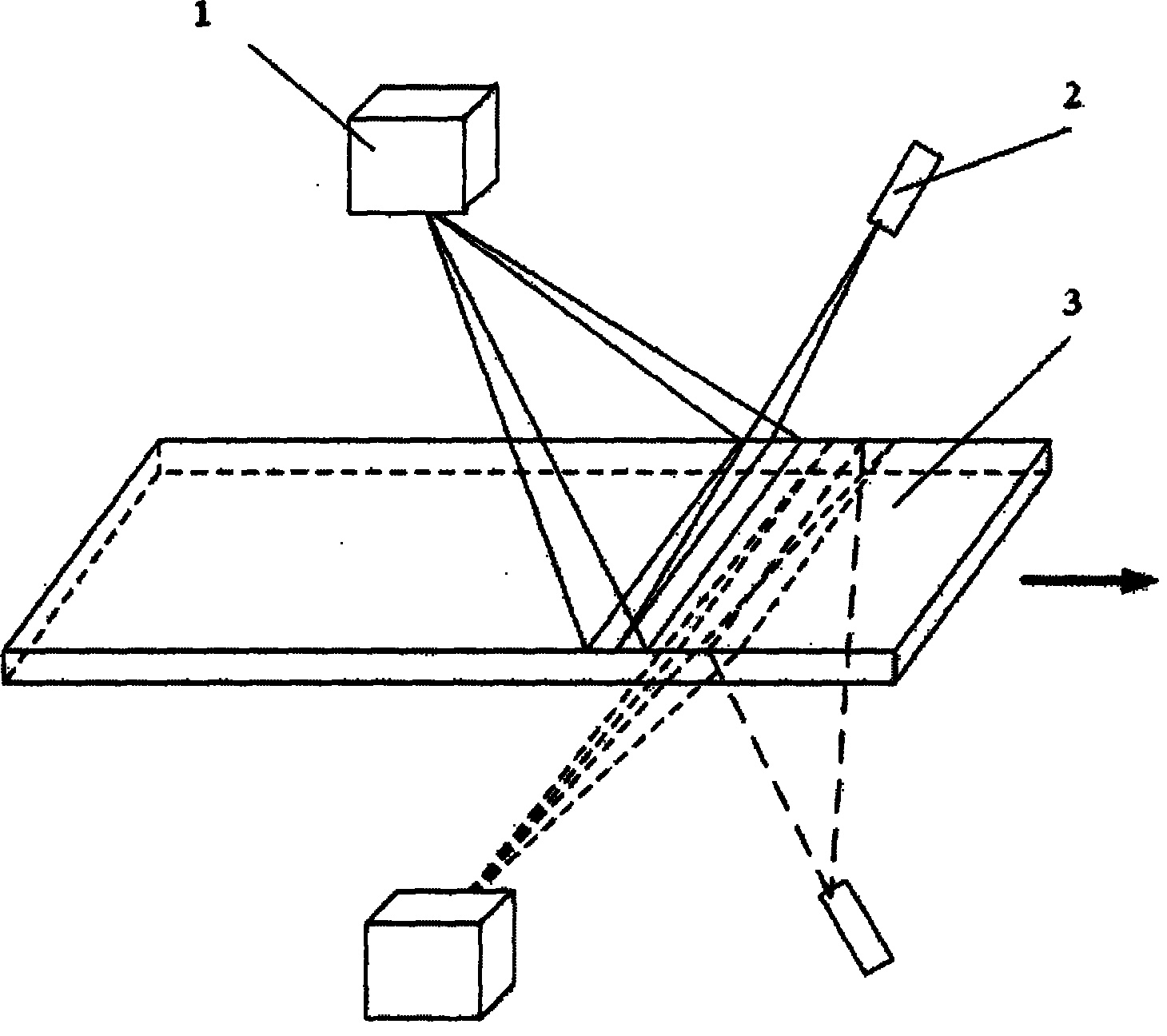

[0016] The aluminum plate flatness visual inspection system of the present invention includes a camera 1 and a laser light source 2, wherein the optical axis of the lens of the camera 1 is perpendicular to the movement plane of the aluminum plate transmission line, and the laser light source 2 and the camera 1 are arranged on the aluminum plate transmission line to move On the same side of the plane, the distance between the laser light source 2 and the camera 1 to the movement plane of the aluminum plate transmission line is equal, the projection direction of the laser light source 2 is at an angle to the movement plane of the aluminum plate transmission line, and the laser light source 2 projects a linear laser to the aluminum plate 3 on the aluminum plate transmission line, The camera 1 photographs the laser projection lines on the aluminum plate 3 , and judges the flatness of the aluminum plate 3 according to the degree of curvature of the laser projection lines in the lines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com