In-place automatic washing device for freeze dryer

A technology for automatic cleaning and freeze drying, which is used in drying, drying solid materials, cleaning methods and utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

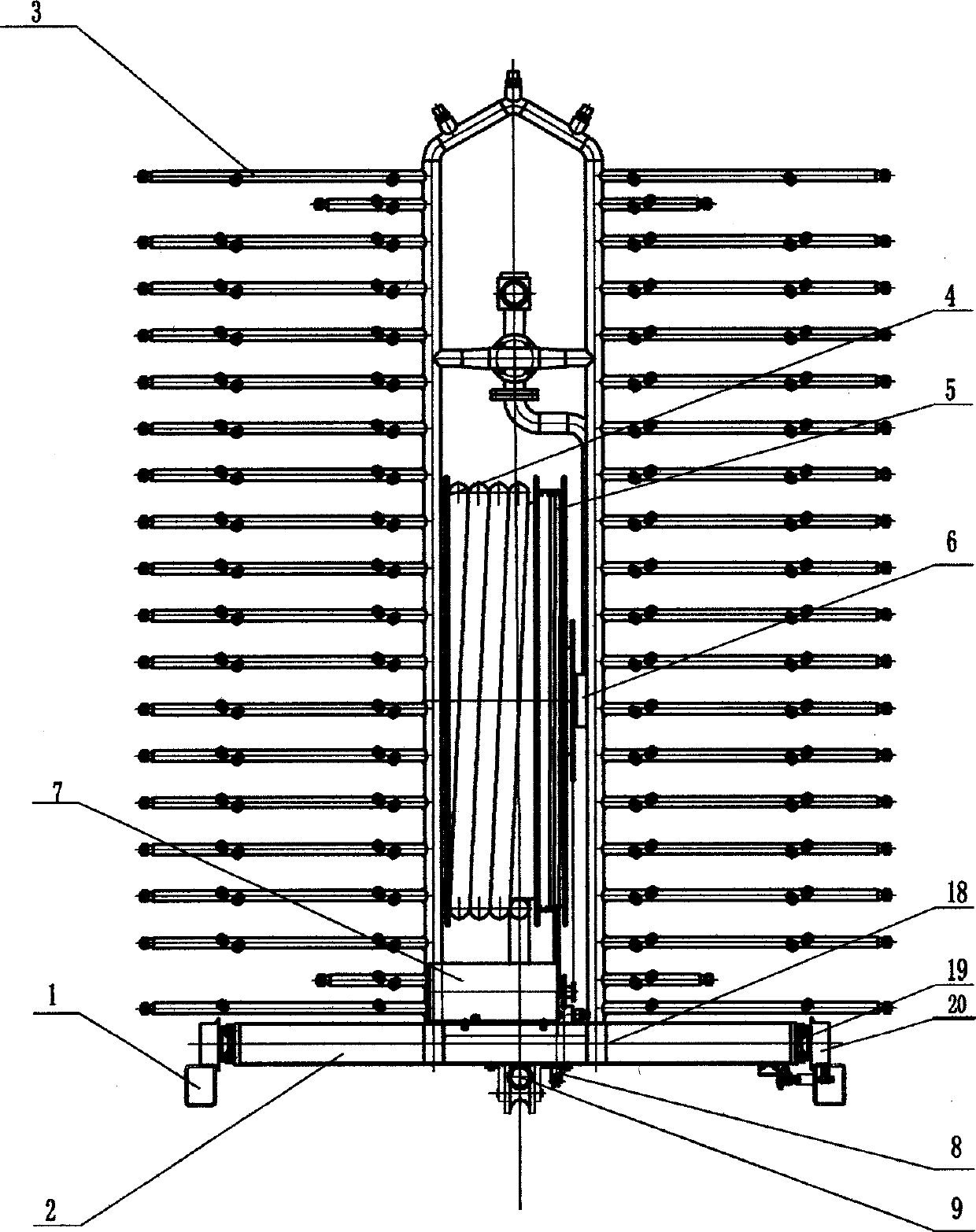

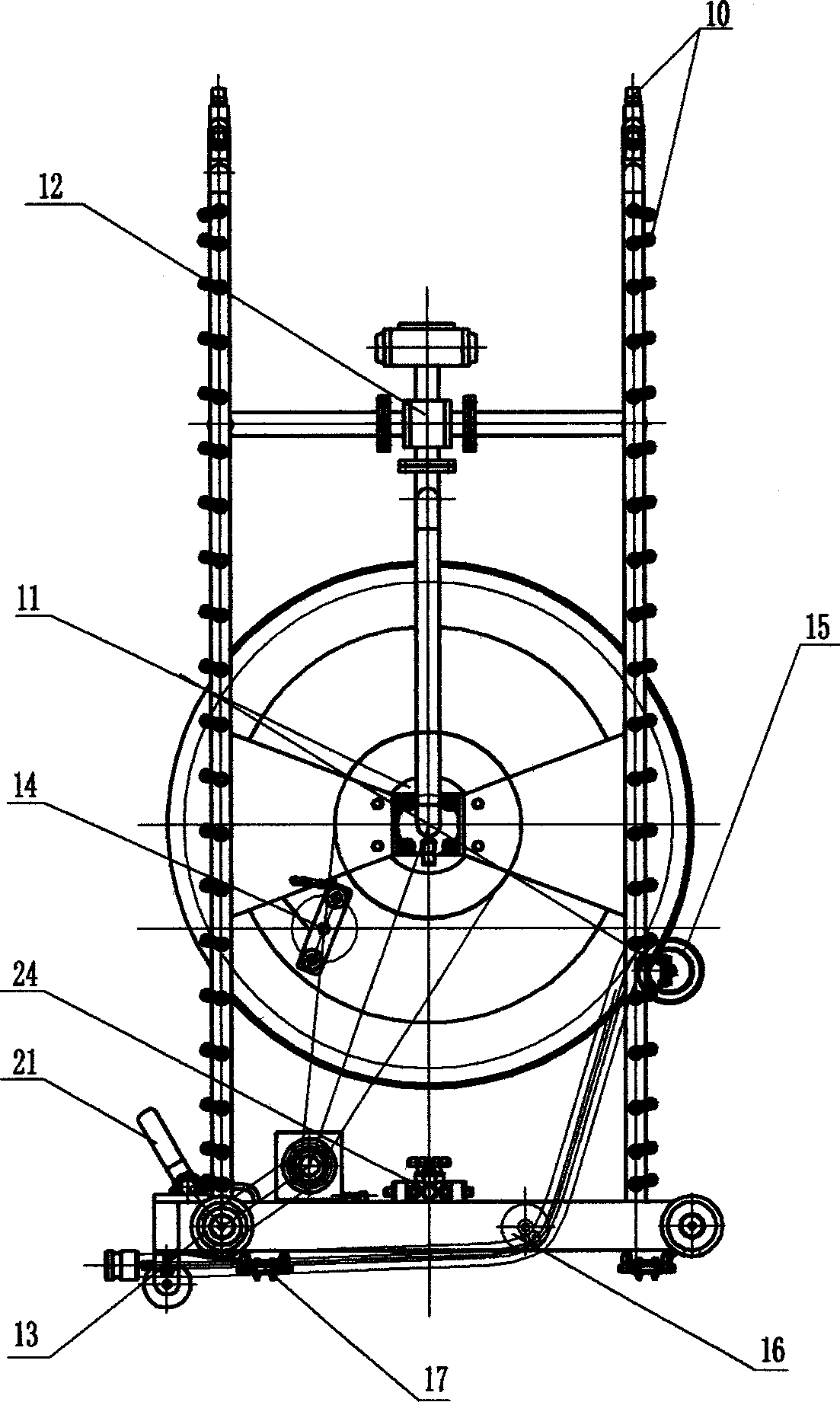

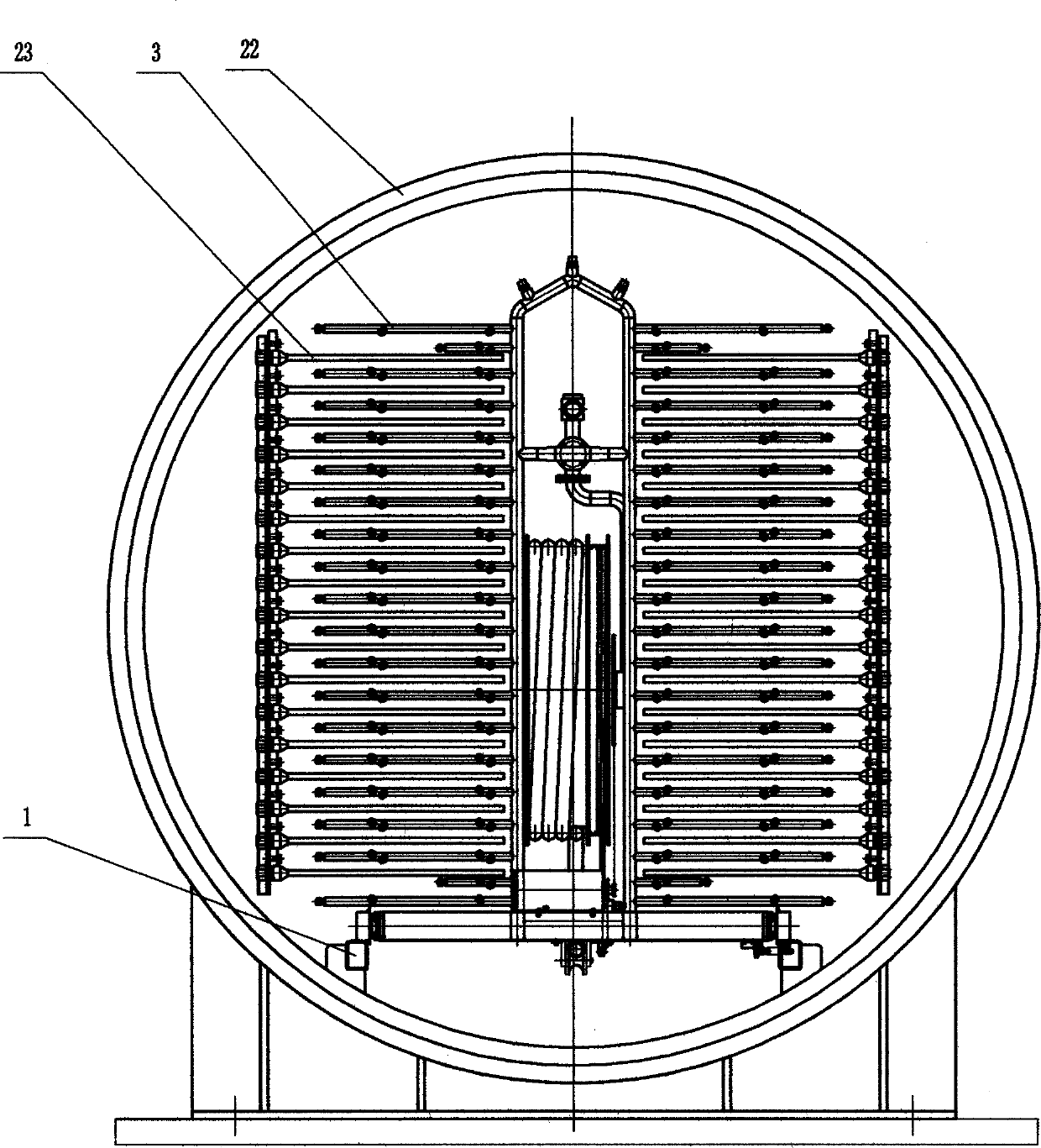

[0013] Including the guide rail 1 that is arranged in the freeze-drying warehouse, the guide rail 1 is provided with a car base 2, and the car base 2 is connected with a cleaning comb frame 3 arranged in layers, and the cleaning comb frame 3 is provided with a nozzle 10, such as figure 1 , 2 As shown, the car base 2 is provided with a water pipe reel 4 and an air pipe reel 5 and is connected to a coaxial reel shaft 6, and the reel shaft 6 is connected to an air motor 7 through a reel chain. The water pipe reel 4 and the air pipe reel 5 are provided with a water pipe and an air pipe whose inlets are respectively connected to the water pipe joint 9 and the air pipe joint 8 located at the lower end of the car base 2, and the water pipe and the air pipe outlet are connected to the pneumatic valve 12 through the rotary joint 11, The outlet of the pneumatic valve 12 is connected to the cleaning comb frame 3 .

[0014] The output shaft of the air motor 7 is provided with two transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com