An in-situ automatic cleaning device for a freeze dryer

A technology of automatic cleaning and freeze-drying machine, which is applied in the direction of drying, drying solid materials, cleaning methods and utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

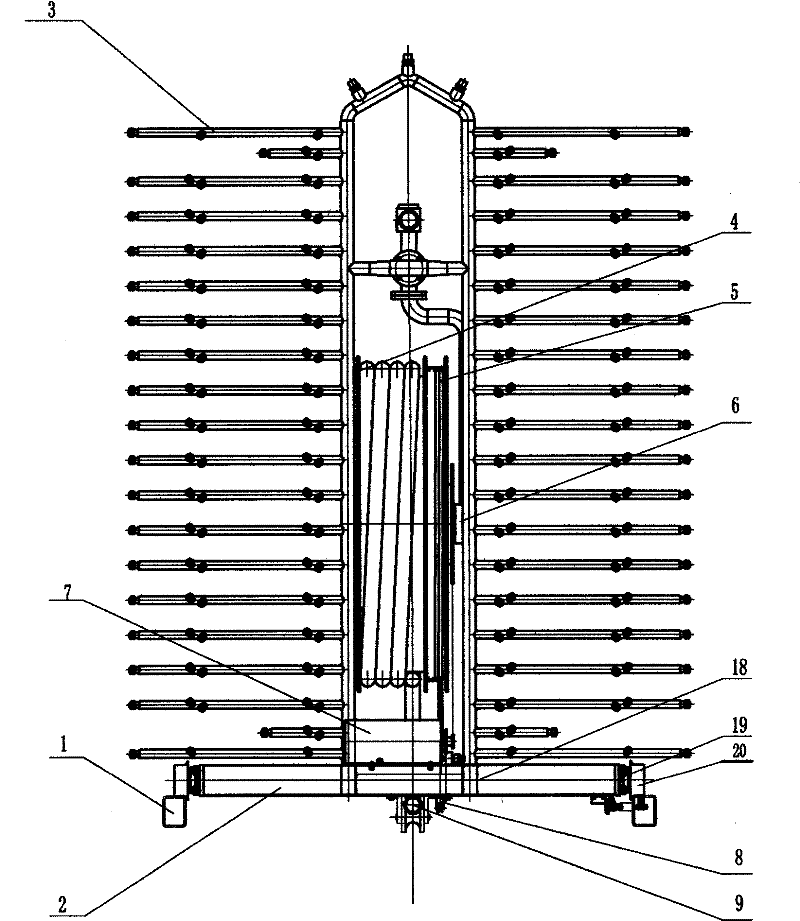

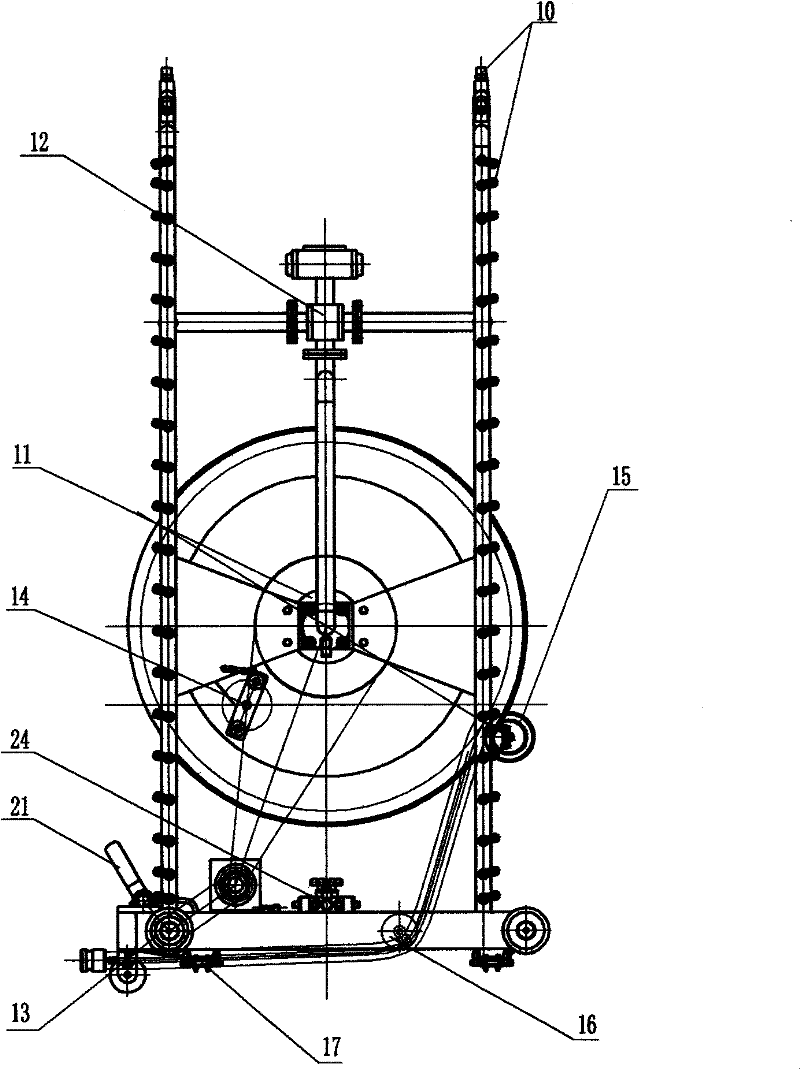

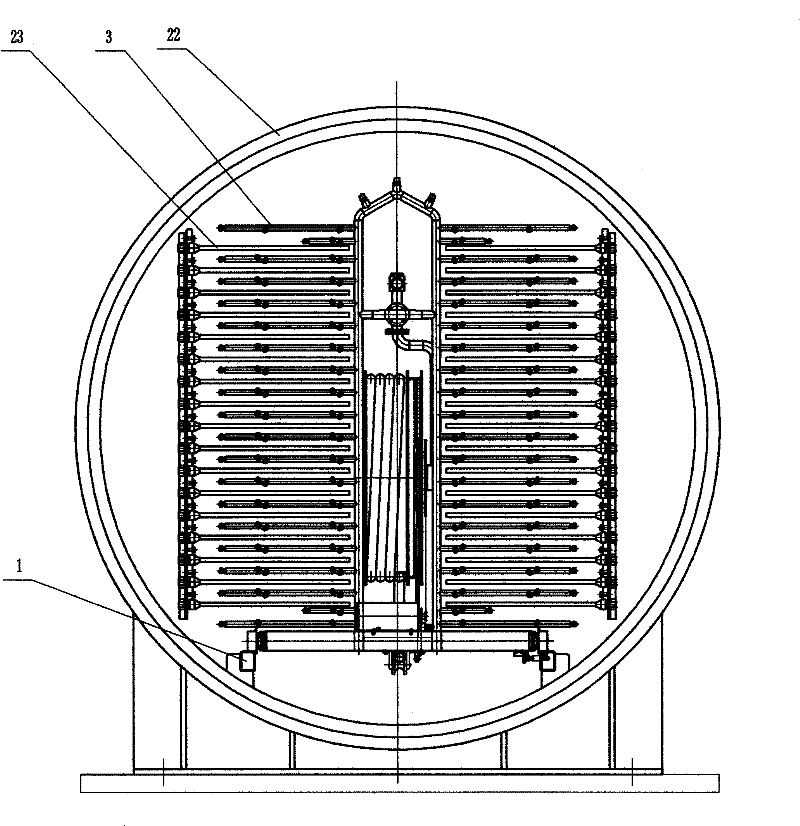

[0013] Including the guide rail 1 that is arranged in the freeze-drying warehouse, the guide rail 1 is provided with a car base 2, and the car base 2 is connected with a cleaning comb frame 3 arranged in layers, and the cleaning comb frame 3 is provided with a nozzle 10, such as figure 1 , 2 As shown, the car base 2 is provided with a water pipe reel 4 and an air pipe reel 5 and is connected to a coaxial reel shaft 6, and the reel shaft 6 is connected to an air motor 7 through a reel chain. The water pipe reel 4 and the air pipe reel 5 are provided with a water pipe and an air pipe whose inlets are respectively connected to a water pipe joint 9 and an air pipe joint 8 located at the lower end of the car base 2, and the outlet of the water pipe and the air pipe is connected to a pneumatic valve 12 through a rotary joint 6, The outlet of the pneumatic valve 12 is connected to the cleaning comb frame 3 .

[0014] The output shaft of the air motor 7 is provided with two transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com