Embedded package structure of LED light source

A technology of LED light source and packaging structure, applied in the direction of light source, electric light source, light source fixing, etc., can solve the problems of unstable current, many ghosts, and uncompact structure, so as to improve the heat dissipation efficiency, expand the heat dissipation area, and help processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

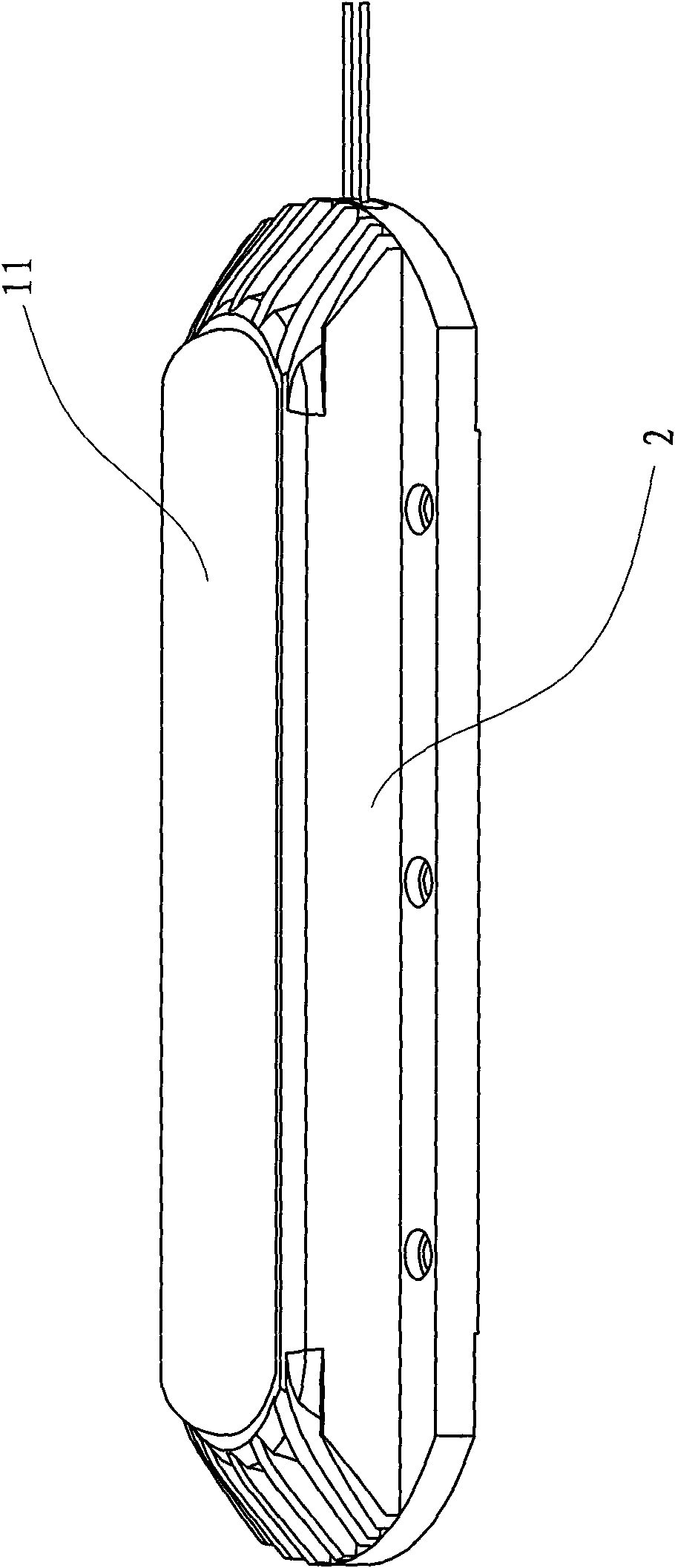

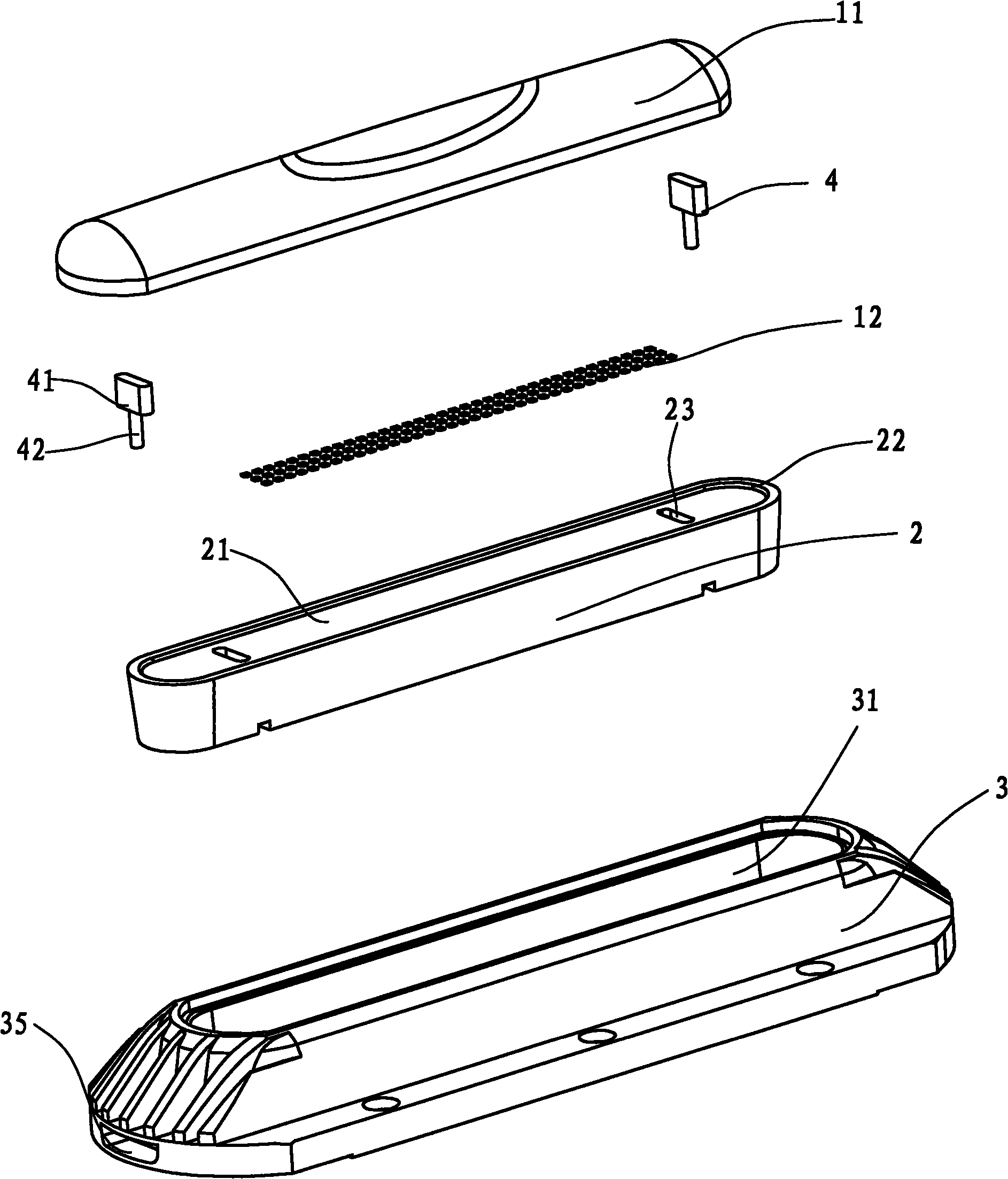

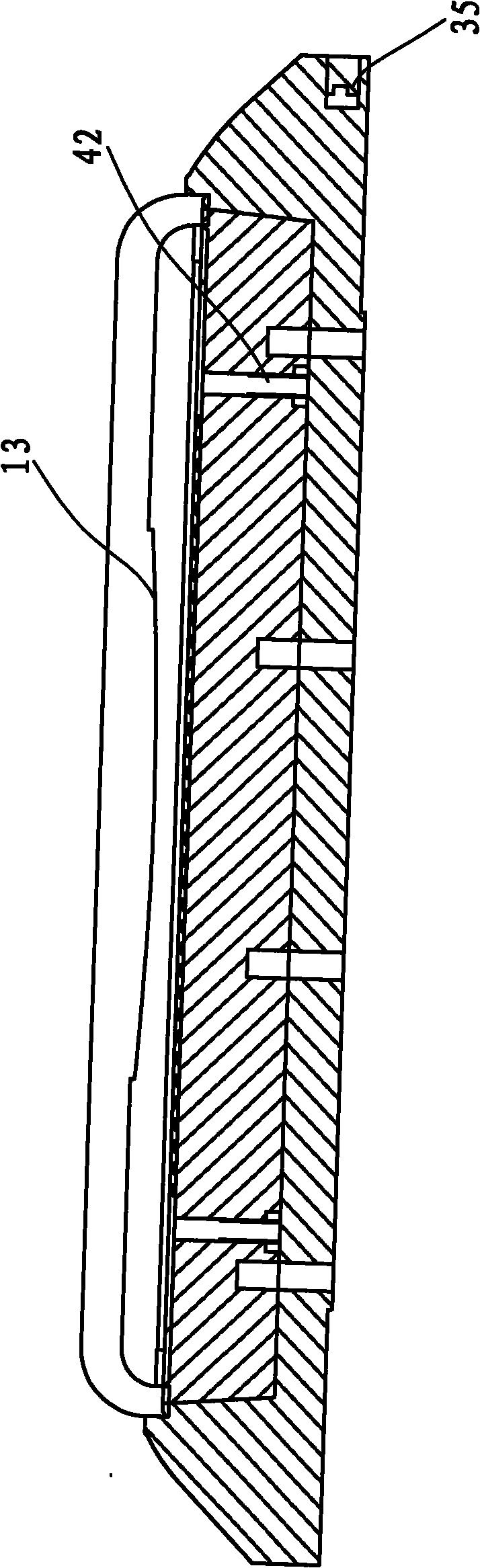

[0021] see Figure 1-3 , an embedded packaging structure of an LED light source, comprising an LED light source, a bracket 2 and a base 3 . The LED light source is strip-shaped, including an optical lens 11 and an LED chip 12. The surface of the optical lens 11 is a sloped semicircle convex shape, and the inside is concave 13. The insulating bottom of the LED chip 12 is on the operating point required by the light source packaging process. Electrically and thermally conductive silver glue. The optical lens 11 is set above the LED chip 12. It adopts diffuse reflection and high light transmission optical glass. The lens body is extremely thin and has high light transmission performance. Different lenses can be selected according to different occasions, which solves the problem of difficult light distribution. , and the light source is designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com