A copper-plastic composite pipe

A technology of copper-plastic composite and copper pipes, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., and can solve problems such as liquid leakage and poor fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

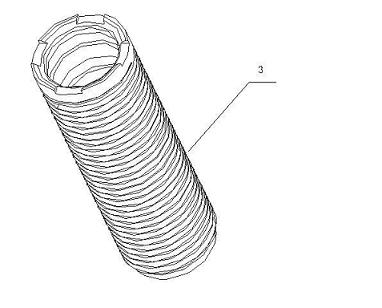

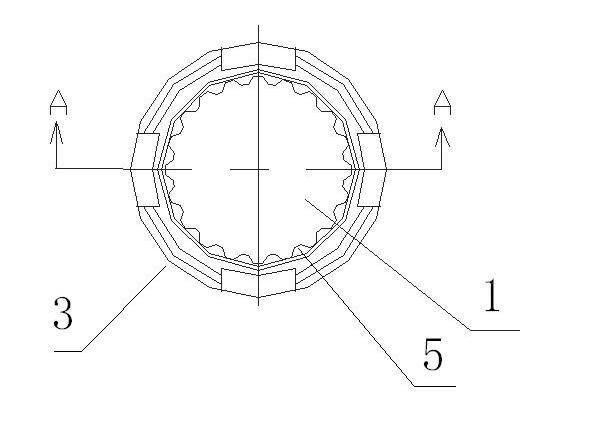

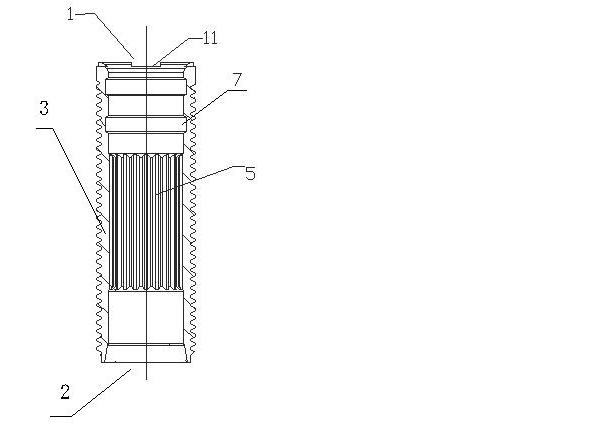

[0033] The copper-plastic composite pipe in this embodiment has a first open end 1 and a second open end 2. The copper-plastic composite pipe includes a copper pipe layer 3 (see figure 1 with figure 2 ) And the plastic pipe layer 4 located inside the copper pipe layer 3 (see Figure 4 ), the plastic tube layer 4 radially wraps the end of the copper tube layer 3 at the first open end 1 and forms a wrapper 8, and the wrapper 8 forms an edge on its radial edge Fold 9 extending in the direction of the second open end 2 of the copper tube layer 3 (see Figure 4 ), here, the height of the folded back 9 is 1mm, the inner wall of the folded back 9 and the outer wall of the copper tube layer 3 are attached and fixed; the end surface of the first open end 1 of the copper tube layer 3 is formed with A square groove 11 is formed on the wrapping portion 8 with a square boss that is matched and fixed with the square groove 11. Here, there are four square grooves 11; the copper tube layer 3 ...

Embodiment 2

[0035] The copper-plastic composite pipe in this embodiment has a first open end 1 and a second open end 2. The copper-plastic composite pipe includes a copper pipe layer 3 (see figure 1 with figure 2 ) And the plastic pipe layer 4 located inside the copper pipe layer 3 (see Figure 4 ), the plastic tube layer 4 radially wraps the end of the copper tube layer 3 at the first open end 1 and forms a wrapper 8, and the wrapper 8 forms an edge on its radial edge Fold 9 extending in the direction of the second open end 2 of the copper tube layer 3 (see Figure 4 ), here, the height of the folded back 9 is 2mm, the inner wall of the folded back 9 and the outer wall of the copper tube layer 3 are attached and fixed; the end surface of the first open end 1 of the copper tube layer 3 is formed with A square groove 11 is formed on the wrapping portion 8 with a square boss that is matched and fixed with the square groove 11, where there are eight square grooves 11; the copper tube layer 3...

Embodiment 3

[0037] The copper-plastic composite pipe in this embodiment has a first open end 1 and a second open end 2. The copper-plastic composite pipe includes a copper pipe layer 3 (see figure 1 with figure 2 ) And the plastic pipe layer 4 located inside the copper pipe layer 3 (see Figure 4 ), the plastic tube layer 4 radially wraps the end of the copper tube layer 3 at the first open end 1 and forms a wrapper 8, and the wrapper 8 forms an edge on its radial edge Fold 9 extending in the direction of the second open end 2 of the copper tube layer 3 (see Figure 4 ), here, the height of the folded back 9 is 3mm, the inner wall of the folded back 9 and the outer wall of the copper tube layer 3 are attached and fixed; the end surface of the first open end 1 of the copper tube layer 3 is formed with A square groove 11 is formed on the wrapping portion 8 with a square boss that is matched and fixed with the square groove 11. Here, there are six square grooves 11; the copper tube layer 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com