Optimization method of particle gradation of blasting rockfill materials based on fractal theory

A technology of fractal theory and optimization method, applied in the field of earth-rockfill dam construction, can solve problems such as quantitative evaluation of the compaction characteristics of rockfill materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] This implementation case is a certain project that has been built. The blasting test adopts the deep hole step blasting method. The rockfill material in the on-site rolling test is compacted with a YZT16 vibrating roller. The number of rolling times is 8 times, and the thickness of the rolling layer is 80cm.

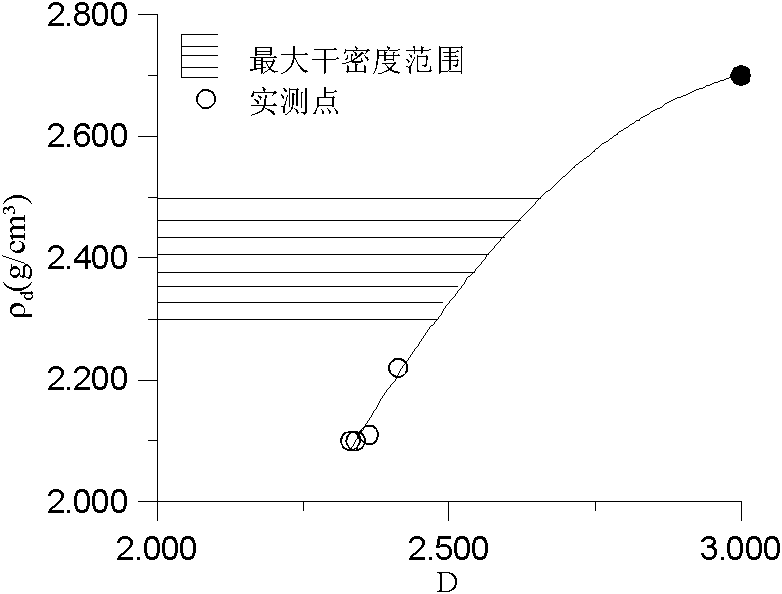

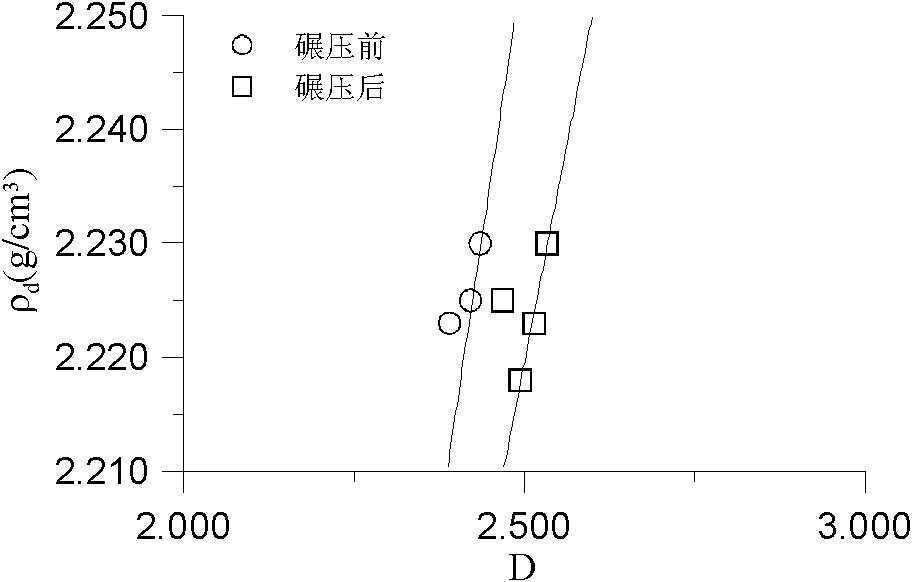

[0068] 1. The relationship between compacted dry density and particle size fractal dimension

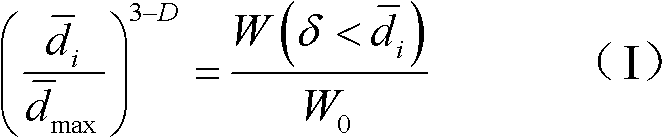

[0069] During the on-site vibration rolling test, the dry density value and the particle size distribution of the particle gradation of the rockfill material detected by the pit method are shown in Table 1. According to the particle size distribution of each group of rolling test rockfill materials, according to formula (I) The corresponding particle size fractal dimension D is also listed in Table 1.

[0070]

[0071] Table 1

[0072] The fractal dimensions of particle size before and after rolling and the measured values of dry density of rockfill materials obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com