Wire rope plug-in device

A technology of plug-in device and steel wire rope, which is applied in auxiliary devices for rope making, textiles and papermaking, textile cables, etc. It can solve problems affecting construction quality, looseness, and damage to galvanized layers, so as to reduce physical labor intensity and make The effect of standardizing the process and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

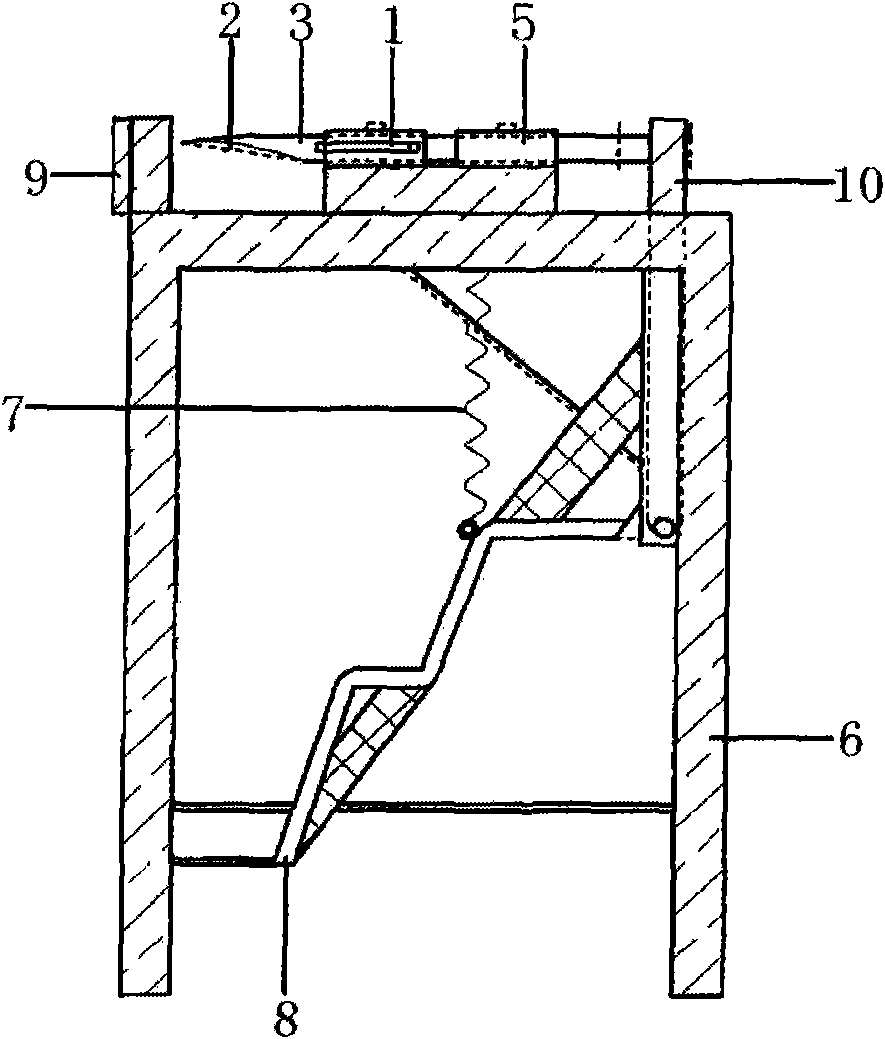

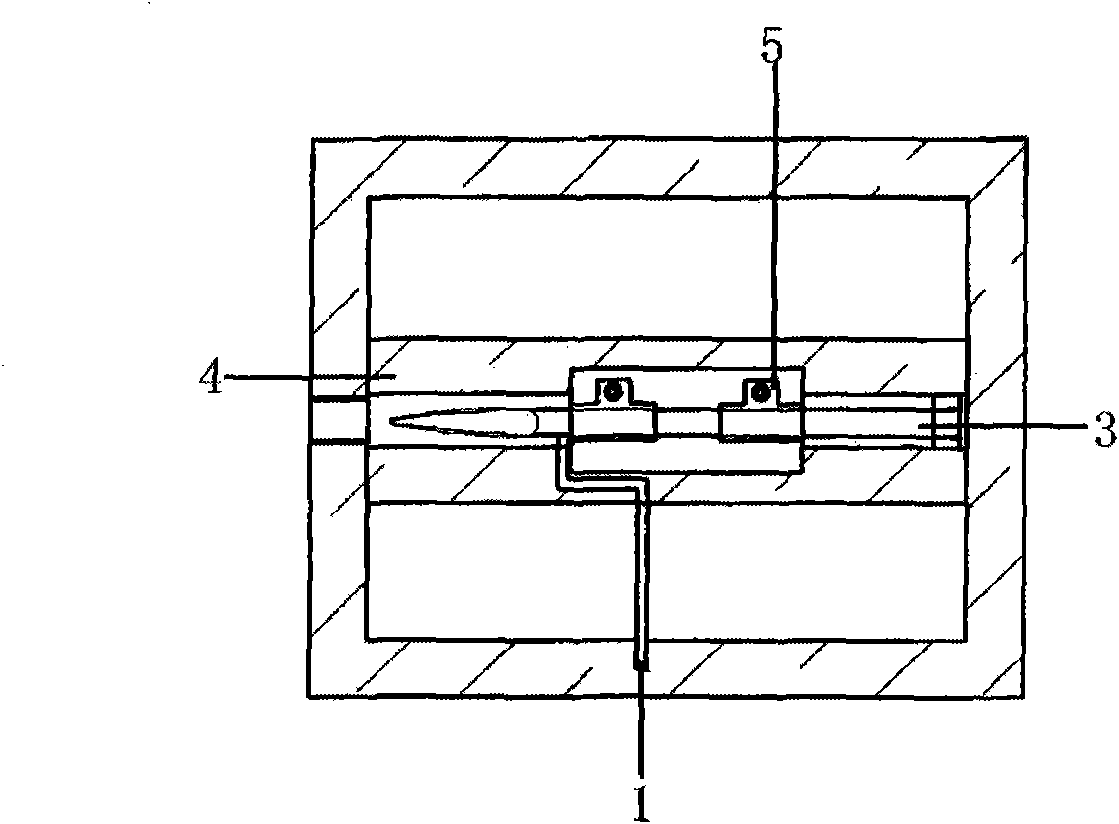

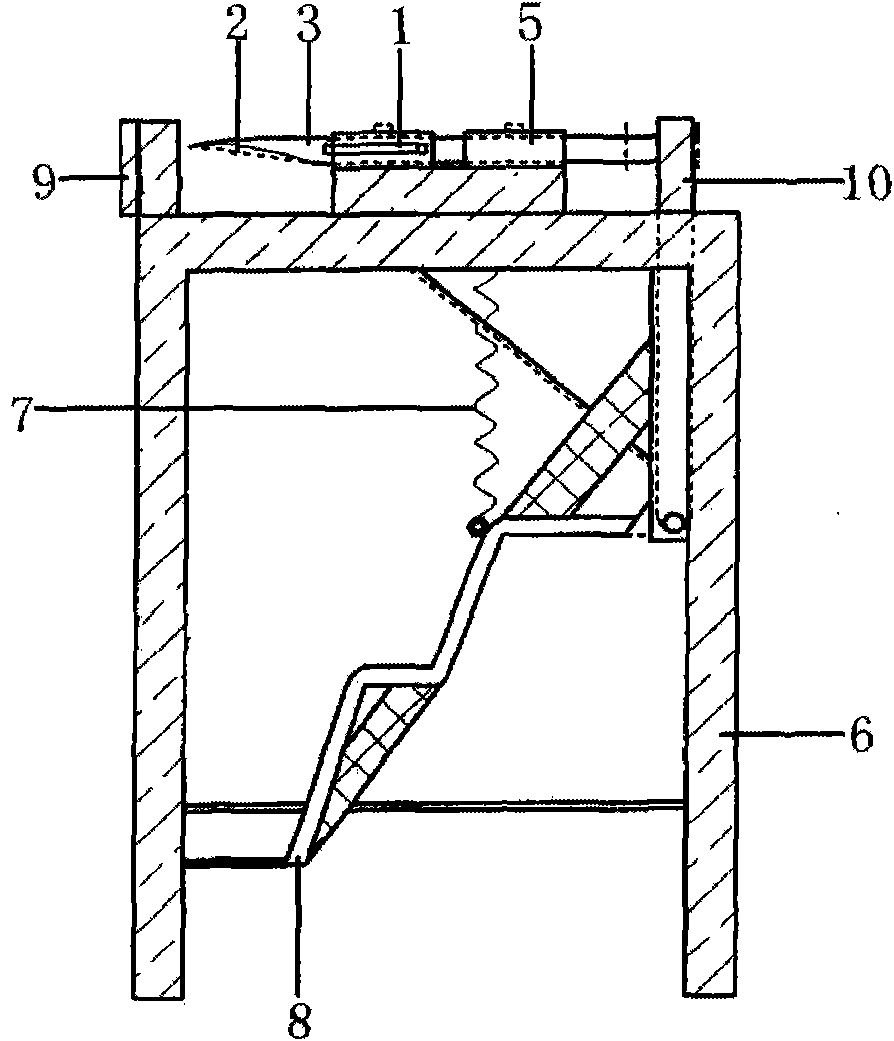

[0009] Embodiment: The device is composed of an operating handle 1, an introduction groove 2, a needle threading 3, a guide rail 4, a fixing clip 5, a bracket 6, a spring 7, a pedal 8, a baffle plate 9, and a push rod 10. The threading needle 3 is fixed by The clamp 5 is fixed on the guide rail 4 of the bracket 6, the side of the needle 3 has an operating handle 1, the needle of the needle 3 has an introduction groove 2, the tail end of the needle 3 is stuck on the upper end of the ejector rod 10, and the lower end of the ejector rod 10 is connected to the Foot pedal 8 is also fixed on the support 6, and spring 8 is arranged between foot pedal 8 and guide rail 4, and the needle of threading needle 3 is to the gap of two baffle plates 9 on the support 6.

[0010] The device uses angle steel to cut and weld to make bracket 6. The upper end of bracket 6 is polished with round steel to make needle 3 and weld operation handle 1 on the side of needle 3. Fix clip 5 to fix on bracket 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com