Hot-rolled section steel for gas cylinder and production method thereof

A gas cylinder and section steel technology, applied in the field of metallurgy, can solve the problems of high cost and low efficiency, and achieve the effects of improving low temperature impact performance, simple process and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

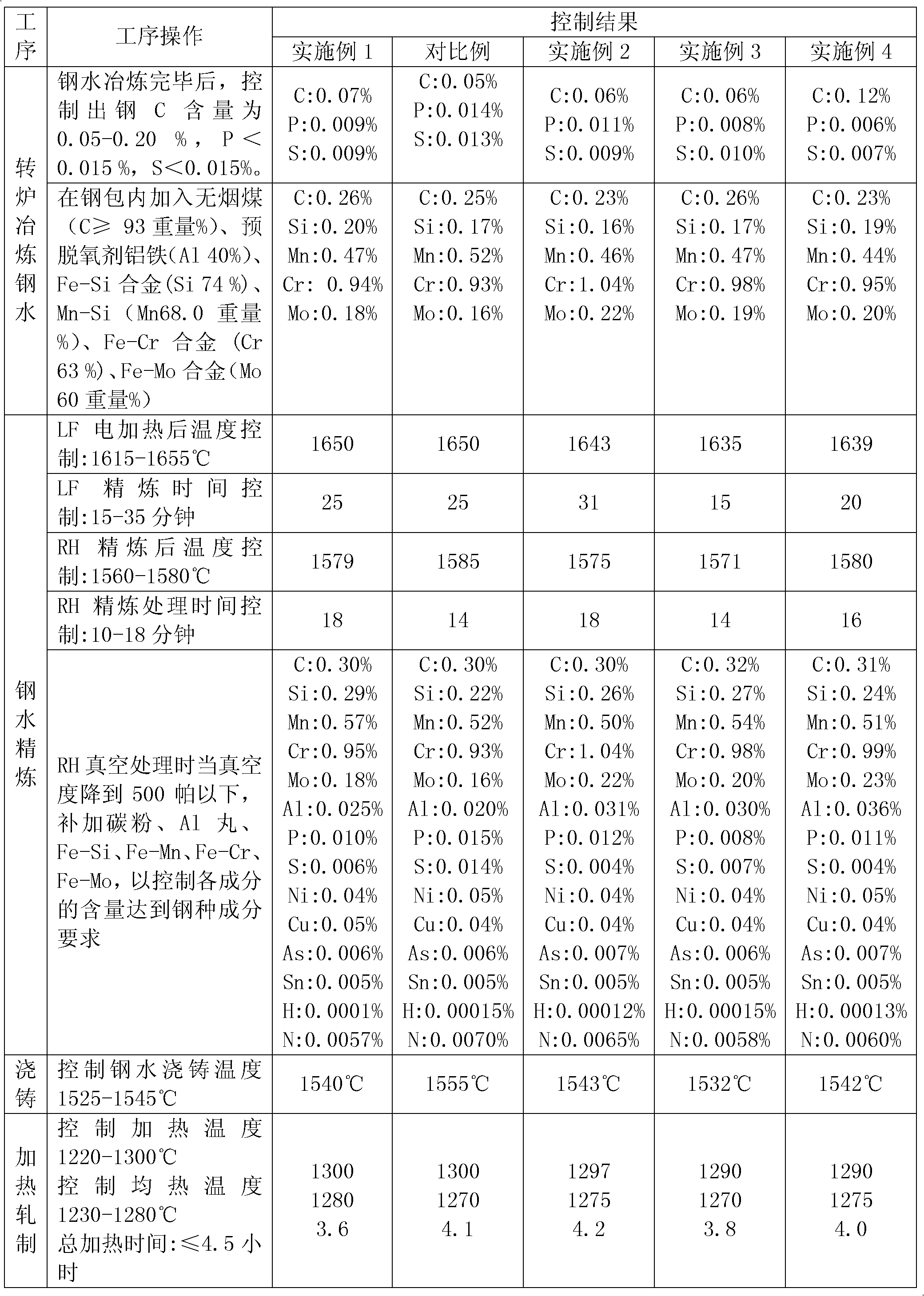

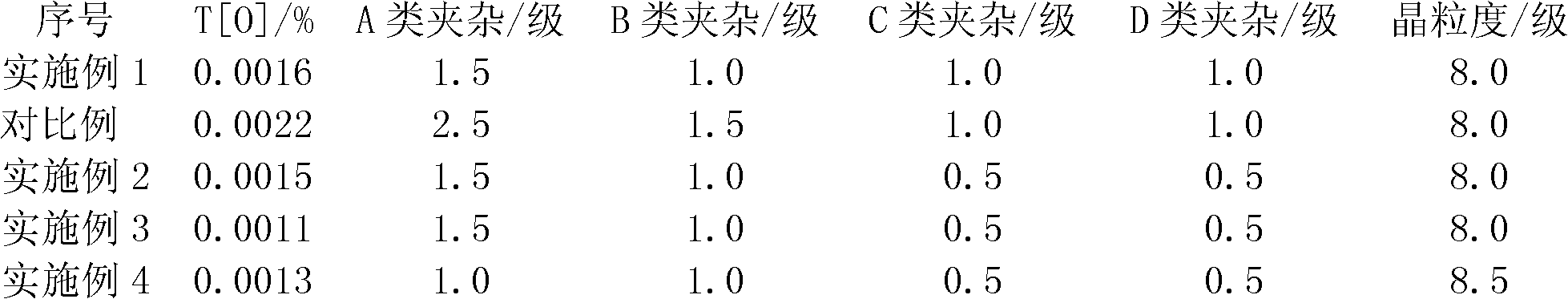

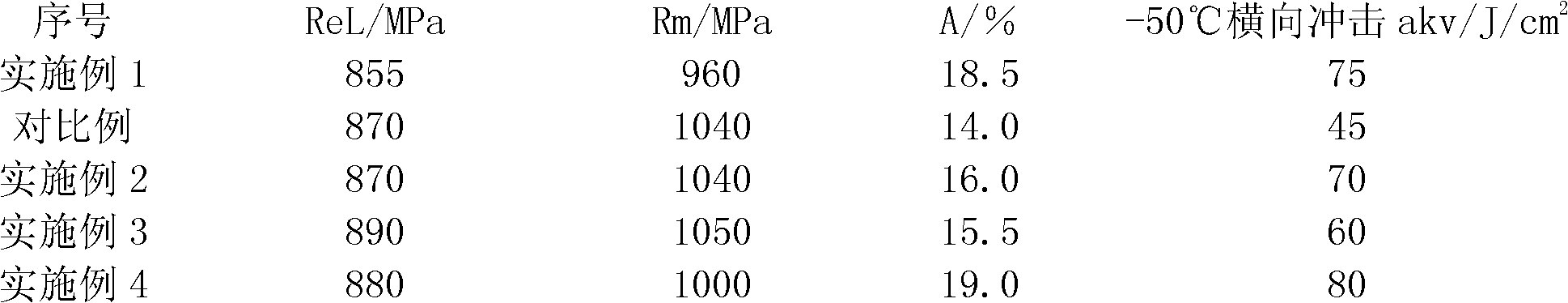

Examples

Embodiment 1

[0031] Embodiment 1 Production of hot-rolled section steel for gas cylinder

[0032] Pour the desulfurized molten iron into the oxygen top-blown converter for blowing. Based on the total weight of the molten steel, when the C content in the molten steel is 0.07 wt%, the P content is 0.009 wt%, and the S content is 0.009 wt%. in ladle. When tapping, relative to each ton of molten steel, first add 2.1 kg of anthracite (C content ≥ 93% by weight) to increase carbon, and after tapping 1 / 3, relative to each ton of molten steel, first add pre-deoxidizer aluminum to the ladle Ferroalloy (Al content is 40% by weight, Anyang City Hengwang Metallurgical Refractories Co., Ltd.) 3.3 kg, then with respect to each ton of molten steel, add refining slag 5.8 kg, Fe-Si (Si content is 74% by weight, Anyang City Hengwang Metallurgical Refractories Co., Ltd.) 1.9 kg, Mn-Si (Mn content ≥ 68%, Panzhihua Panhong Metallurgical Products Co., Ltd.) 6.7 kg, Fe-Cr (Cr content is 61%, Panzhihua Panhong M...

Embodiment 2

[0037] Embodiment 2 Production of hot-rolled section steel for gas cylinder

[0038]The desulfurized molten iron is poured into an oxygen top-blown converter for blowing. Based on the total weight of the molten steel, when the C content in the molten steel is 0.06% by weight, the P content is 0.011% by weight, and the S content is 0.009% by weight, it is immediately tapped to In the ladle. When tapping, relative to each ton of molten steel, first add 1.9 kg of anthracite (C content ≥ 93% by weight) to increase carbon, and after tapping 1 / 3, relative to each ton of molten steel, first add pre-deoxidizer aluminum to the ladle Ferroalloy (Al content is 40% by weight, Anyang City Hengwang Metallurgical Refractories Co., Ltd.) 3.2 kg, then for each ton of molten steel, add 6.4 kg of refining slag, Fe-Si (Si content is 74% by weight, Anyang City Hengwang Metallurgical Refractories Co., Ltd.) 2.0 kg, Mn-Si (Mn content ≥ 68%, Panzhihua Panhong Metallurgical Products Co., Ltd.) 6.6 kg...

Embodiment 3

[0043] Embodiment 3 Production of hot-rolled section steel for gas cylinder

[0044] The desulfurized molten iron is poured into an oxygen top-blown converter for blowing. Based on the total weight of the molten steel, when the C content in the molten steel is 0.06% by weight, the P content is 0.008% by weight, and the S content is 0.01% by weight, it is immediately tapped to In the ladle. When tapping, relative to each ton of molten steel, first add 2.2 kg of anthracite (C content ≥ 93% by weight) to increase carbon, and after tapping 1 / 3, relative to each ton of molten steel, first add pre-deoxidizer aluminum to the ladle Ferroalloy (Al content is 40% by weight, Anyang Hengwang Metallurgical Refractories Co., Ltd.) 3.1 kg, then with respect to each ton of molten steel, add 5.8 kg of refining slag, Fe-Si (Si content is 74% by weight, Anyang City Hengwang Metallurgical Refractories Co., Ltd.) 2.1 kg, Mn-Si (Mn content ≥ 68.0%, Panzhihua Panhong Metallurgical Products Co., Ltd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com