Sealing composition, multilayer glass and solar cell panel

A sealing composition, a technology for solar cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as reduced power generation efficiency, insufficient durability, and reduced insulation, preventing the reduction of power generation efficiency and excellent shape followability , the effect of preventing performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~7

[0143] Put the ingredients listed in Table 1 into a kneader (DS1-5GHB-E type, 1L kneader, equipped with a 6-inch open mixer, manufactured by MORIYAMA Corporation) at one time according to the formula in Table 1, and knead at 120°C , formulate the sealing composition as a knead.

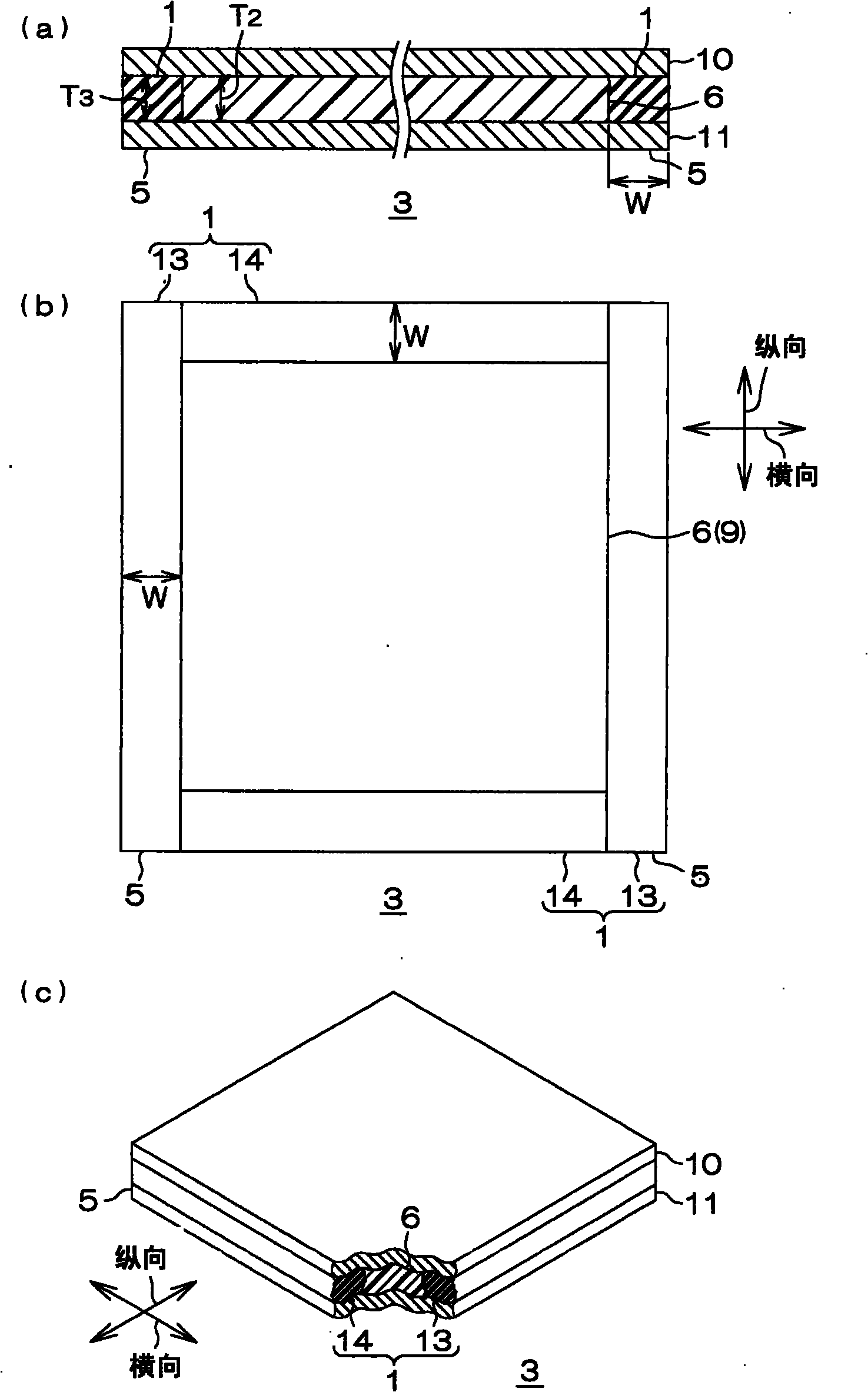

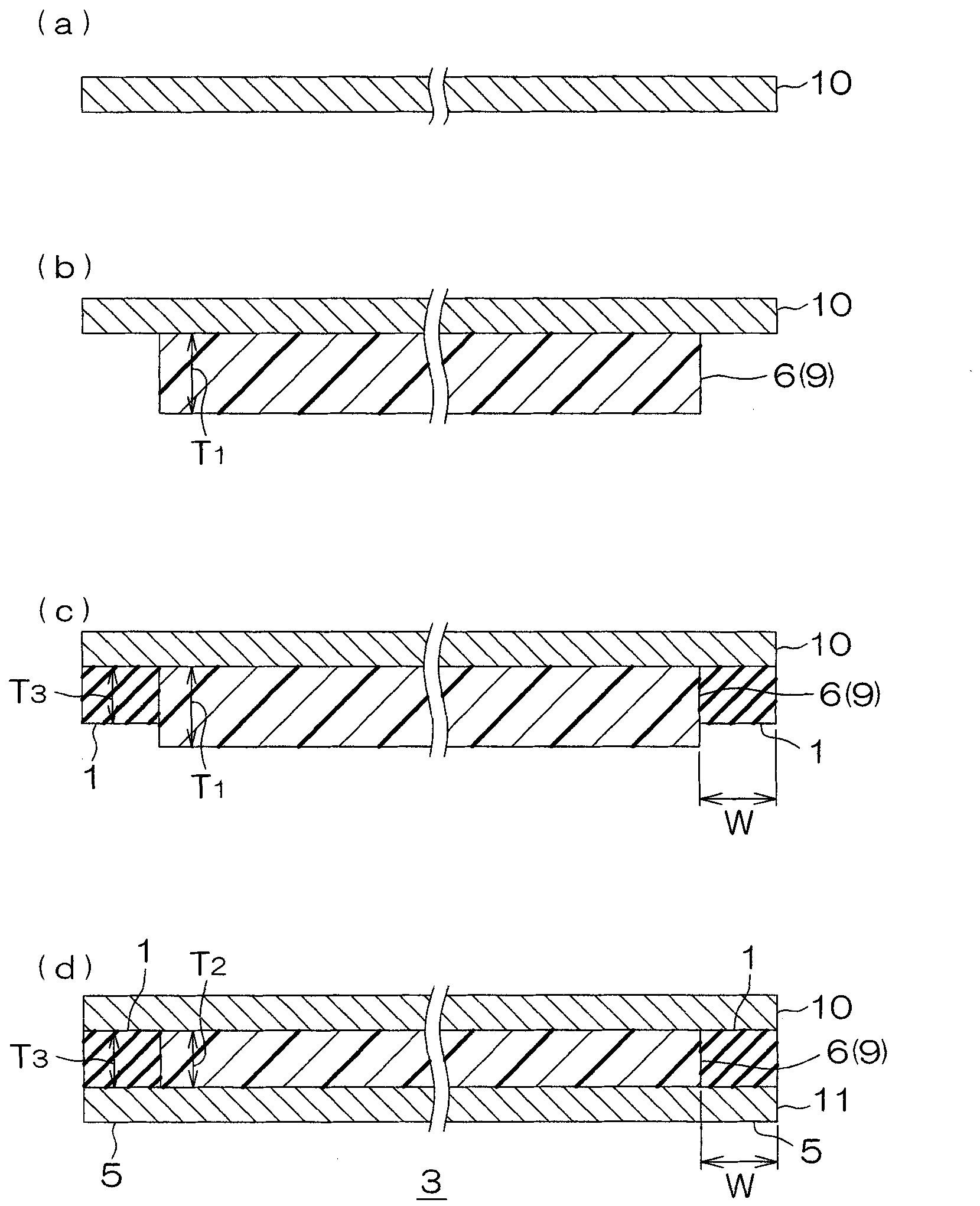

[0144] Then, the obtained kneaded product was calender-molded with a calender (calender 4L-8a, manufactured by Hitachi, Ltd.) to a thickness of 0.75 mm and a thickness of 1.0 mm, respectively, to obtain a sealing material containing the sealing composition. In addition, the rolling conditions of the calender are such that the temperature of the rolls is adjusted to 30 to 90° C., and the temperature of the downstream roll (R′) arranged on the downstream side in the conveying direction with respect to the roll speed (R) of the upstream roll is adjusted. The ratio (R' / R) was adjusted to 1.1.

[0145] Thereafter, a release film is laminated on one side of the sealing material, and wound up in a roll (ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com