Method for preparing 1,3-dioxolane

A dioxolane and ethylene glycol technology, applied in the direction of organic chemistry, can solve the problems of high requirements for reaction vessels, many by-products, and high corrosiveness, and achieve the effects of environmental friendliness, less impurities and less corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

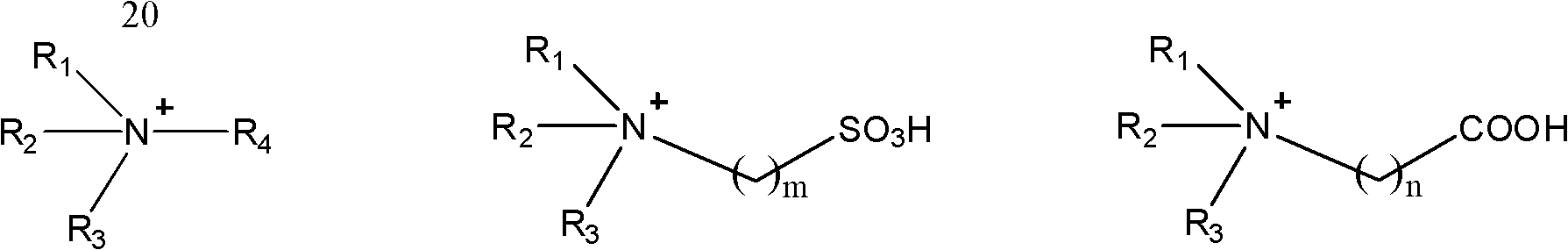

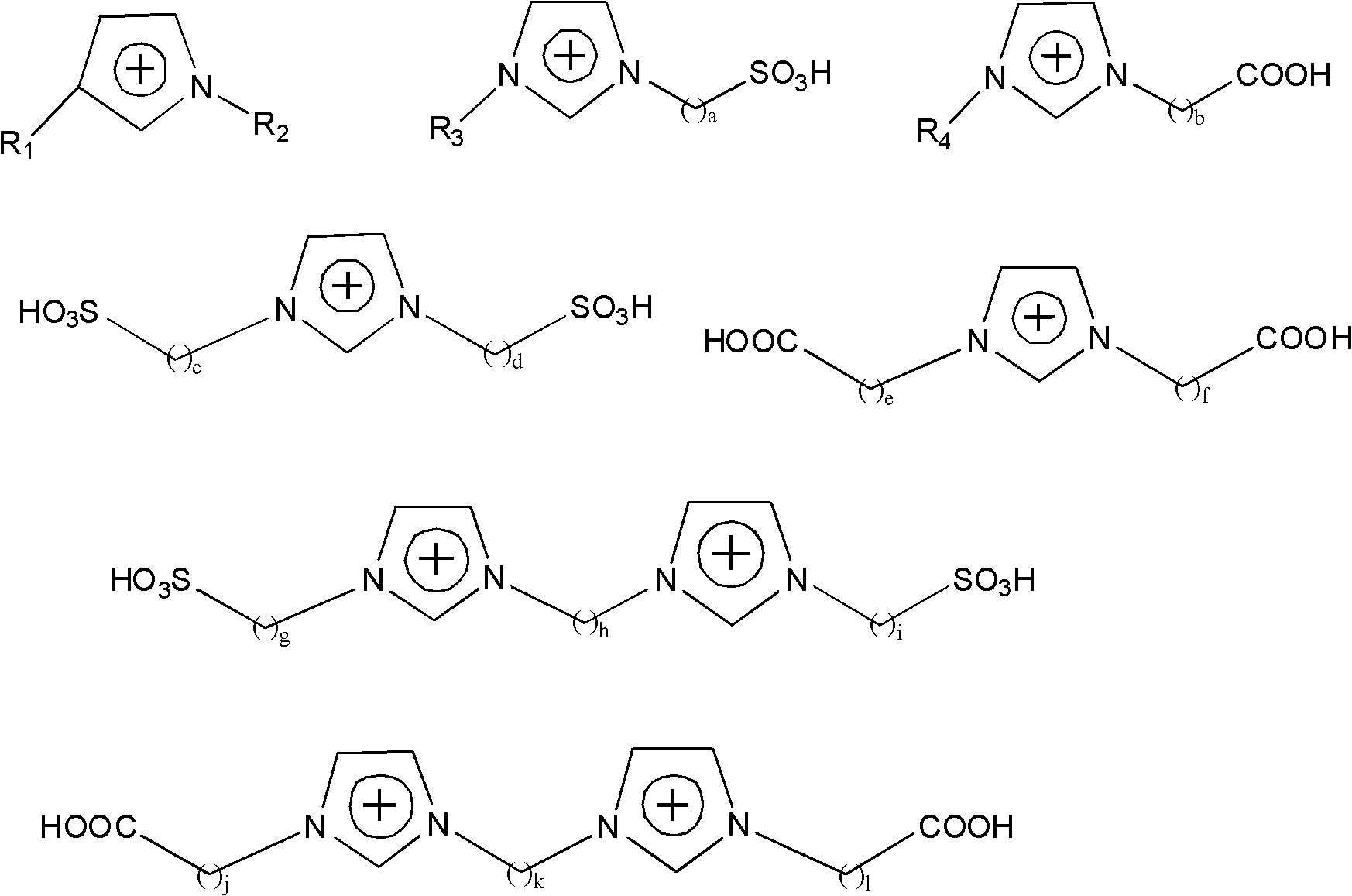

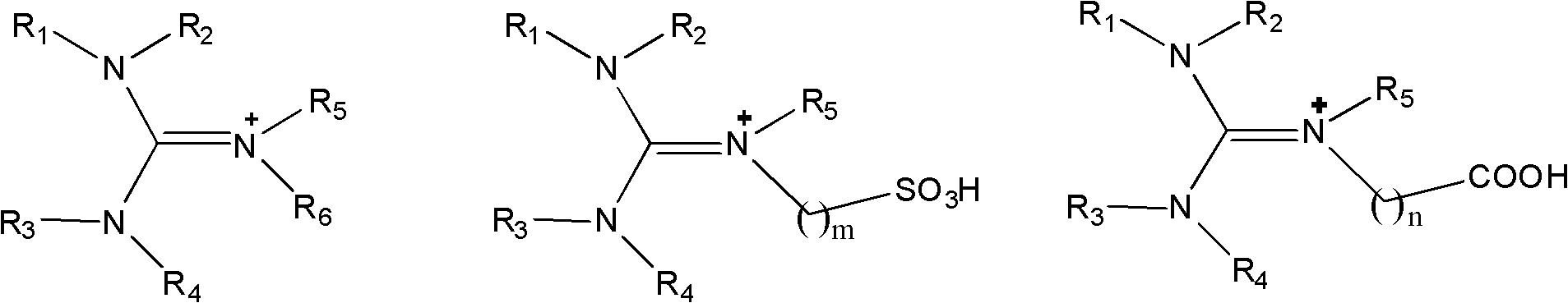

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1 (with 1-butyl-3-methylimidazolium bisulfate as catalyst)

[0055] First in the reactor, adding concentration is 99% ethylene glycol (purchased from Tianjin Hongyan Chemical Reagent Factory) 150mL, then adds 19.2g of 1-butyl-3-methylimidazolium bisulfate as a catalyst, through oil The bath heats the above mixture to around 70°C. Then, 180 mL of concentrated formaldehyde (purchased from Shijiazhuang Huadi Chemical Industry and Trade Co., Ltd.) with a concentration of 54.21% and a temperature of 70° C. was added into the reaction kettle (the mass concentration of the catalyst in the raw material mixture was 5.26 wt %). After uniformly mixing the above raw materials and catalyst, adjust the temperature of the oil bath to 120°C, and after 3 hours of total reflux reaction, set the extracted reflux ratio to 3 and continuously extract the 1,3- The concentration of dioxolane is above 80% on average, and the highest concentration is 93.83%. The product yield is 70....

Embodiment 2

[0056] Embodiment 2 (with 1-(4-sulfonic acid group) butyl-3-methylimidazole p-toluenesulfonate as catalyst)

[0057] First, in the reaction kettle, 150 mL of ethylene glycol (purchased from Tianjin Hongyan Chemical Reagent Factory) with a concentration of 95% was added, and then 15.1 g of 1-(4-sulfonic acid) butyl-3-methylimidazole was added. Tosylate is used as a catalyst, and the above mixture is heated to about 70°C through an oil bath. Then, 170 mL of concentrated formaldehyde (purchased from Shijiazhuang Huadi Chemical Industry and Trade Co., Ltd.) with a concentration of 57.08% and a temperature of 70° C. was added into the reaction kettle (the mass concentration of the catalyst in the raw material mixture was 4.34 wt %). After uniformly mixing the above raw materials and catalyst, adjust the temperature of the oil bath to 120°C, and after 2 hours of total reflux reaction, set the reflux ratio in extraction to 2.5, and extract continuously. The average concentration of ...

Embodiment 3

[0058] Embodiment 3 (with 1-(4-sulfonic acid group) butyl-3-methylimidazole triflate as catalyst)

[0059] First, 150 mL of ethylene glycol (purchased from Tianjin Hongyan Chemical Reagent Factory) with a concentration of 99% was added to the reaction kettle, and then 14.7 g of 1-(4-sulfonic acid group) butyl-3-methylimidazole tris Fluoromethanesulfonate was used as a catalyst, and the above mixture was heated to about 70°C through an oil bath. Then, 165mL of concentrated formaldehyde (purchased from Shijiazhuang Huadi Chemical Industry and Trade Co., Ltd.) with a concentration of 60.24% and a temperature of 70°C was added to the reaction kettle (the mass concentration of the catalyst in the raw material mixture was 4.02wt%). After uniformly mixing the above raw materials and catalyst, adjust the oil bath temperature to 120°C, and after 2 hours of total reflux reaction, set the extracted reflux ratio to 2, and continuously extract the 1,3- The average concentration of dioxola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com