Method for preparing hydroxytyrosol by boiling and hydrolyzing

A technology for hydroxytyrosol and ethanol recovery, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as resin equipment corrosion, and achieve the effects of improving conversion rate, shortening conversion time, and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

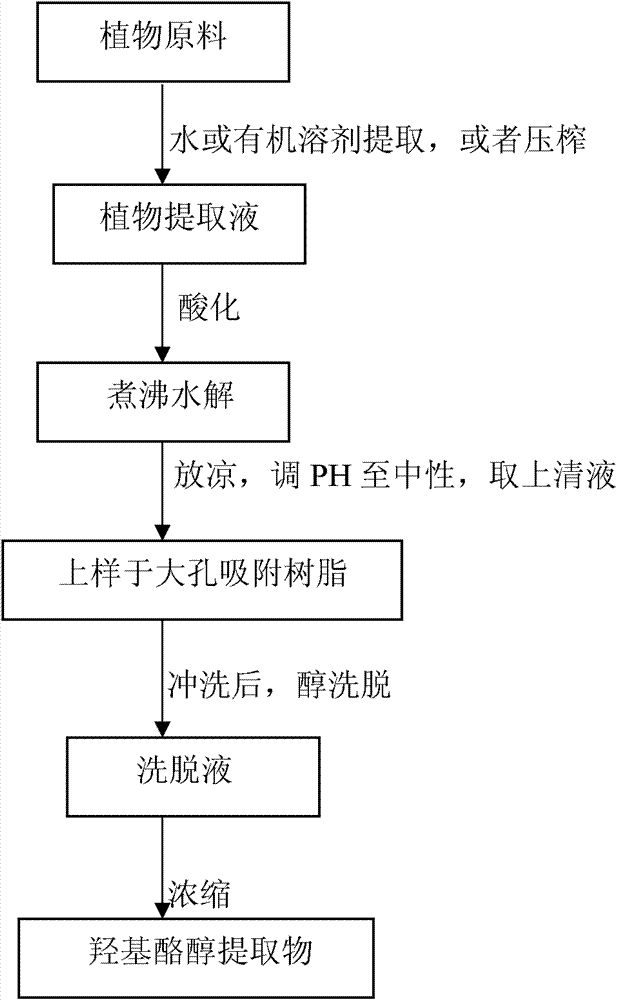

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 The preparation of hydroxytyrosol from Ligustrum lucidum comprises the following steps:

[0031] 1) Preparation of Ligustrum lucidum extract:

[0032] Take 100 grams of Ligustrum lucidum as the raw material, add water to soak for half an hour, decoct and extract 3 times (the amount of water added each time is 8 times the weight of the raw material, 1.5 hours for the first time, 1 hour for the second and third times), combined and decocted solution, concentrated to extract, with a relative density of 1.2, to obtain Ligustrum lucidum extract;

[0033] 2) Take Ligustrum lucidum extract, add concentrated hydrochloric acid to make the PH to 1, boil and hydrolyze for 2 hours under normal pressure, let the obtained hydrolyzate cool, adjust the pH to neutral with sodium hydroxide, filter, and take the supernatant;

[0034] 3) Apply the supernatant to DM130 macroporous adsorption resin column chromatography. After the adsorption is completed, rinse with water to re...

Embodiment 2

[0036] Example 2 The preparation of hydroxytyrosol from Frangipani Frangipani comprises the following steps:

[0037] 1) Preparation of Frangipani Fructus Extract:

[0038] Take 100 grams of Frangipani japonica as raw material, add water to decoct and extract 3 times (the amount of water added each time is 10 times the weight of the raw material, and extract for 1 hour each), combine the decoction liquid, concentrate to extract, and the relative density is 1.1 to obtain Frangipani extract;

[0039] 2) Take the extract of Frangipani japonica, add concentrated hydrochloric acid to make the PH to 2, boil and hydrolyze for 3 hours under normal pressure, let the obtained hydrolyzate cool, adjust the pH to neutral (7.0) with sodium hydroxide, filter, and take the supernatant ;

[0040] 3) Apply the supernatant to XDA10 macroporous adsorption resin column chromatography. After the adsorption is completed, rinse with water to remove impurities until the washing liquid becomes clear,...

Embodiment 3

[0042] Embodiment 3 olives prepare hydroxytyrosol, comprising the following steps:

[0043] 1) Preparation of olive extract:

[0044] Take 200 grams of fresh olive fruit as a raw material, press to extract the juice, concentrate to extract, the specific gravity is about 1.3, and the olive extract is obtained.

[0045] 2) Take the olive extract, add concentrated hydrochloric acid to make the pH 2, boil and hydrolyze for 4 hours under normal pressure, let the obtained hydrolyzate cool, adjust the pH to neutral (7.2) with sodium hydroxide, filter, and take the supernatant;

[0046] 3) Apply the supernatant to D101 macroporous adsorption resin column chromatography. After the adsorption is completed, rinse with water to remove impurities until the washing liquid becomes clear, then elute with 25% ethanol, and collect the eluate;

[0047]4) Concentrate and dry the collected eluate and recover ethanol to obtain 0.9 g of hydroxytyrosol extract with a purity of 35.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com