A resistance brazing method for galvanized steel sheets

A galvanized steel sheet, resistance brazing technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of non-dense solder joints, poor weldability, unstable joint strength, etc., to achieve corrosion resistance and The effect of electrode life, reducing welding temperature and welding pressure, and solving the problem of spot welding electrode failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

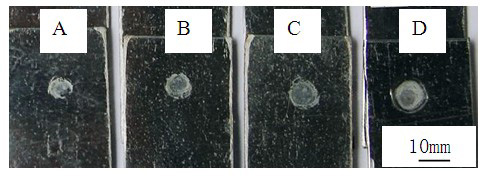

[0016] Embodiment 1: Resistance brazing of DX51D double-sided hot-dip galvanized steel sheet

[0017] The thickness of the DX51D double-sided hot-dip galvanized steel sheet is 0.9mm, and the thickness of the double-sided galvanized layer is 16.8μm; the brazing material is ZA5 alloy (weight percentage: Zn: 89.3%, Al: 4.2%, Cu: 3.22%, Mg : 0.82%, Mn: 0.91%, Si: 0.81%, and the balance is impurities), the thickness is 0.3mm, and the size is a circular solder sheet with a diameter of 12mm. The electrode pressure is 0.2MPa, the welding time is 20C, 50C, the welding current is 6000~12000A, the electrode material is Cr-Zr-Cu, and the electrode diameter is 10mm.

[0018] Place the solder on the surface to be welded of two DX51D double-sided hot-dip galvanized steel sheets, set the resistance spot welding parameters, welding current, welding time and welding pressure, start the resistance spot welding, and then let the weldment cool naturally.

[0019] Its mechanical properties are lis...

Embodiment 2

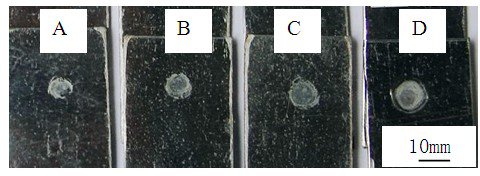

[0023] Embodiment 2: Resistance brazing of DX51D double-sided hot-dip galvanized steel sheet

[0024] The thickness of the DX51D double-sided hot-dip galvanized steel sheet is 0.58mm, and the thickness of the double-sided galvanized layer is 16.8μm; the solder is ZA5 alloy (weight percentage: Zn: 89.3%, Al: 4.2%, Cu: 3.22%, Mg: 0.82%, Mn: 0.91%, Si: 0.81%, and the balance is impurities), the thickness is 0.2mm, and the size is a circular brazing sheet with a diameter of 12mm. The electrode pressure is 0.2MPa, the welding time is 20C, the welding current is 10000A, the electrode material is Cr-Zr-Cu, and the electrode diameter is 10mm.

[0025] Place the solder on the surface to be welded of two DX51D double-sided hot-dip galvanized steel sheets, set the resistance spot welding parameters, welding current, welding time and welding pressure, start the resistance spot welding, and then let the weldment cool naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com