Breathing tube control valve and gas pipeline for connecting the control valve

A gas pipeline and control valve technology, applied in the field of medical equipment, can solve problems such as inconvenience, pipeline cut or cut, large pressure difference between inside and outside of the valve plate, etc., to reduce noise and solve problems and inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the features and technical contents of the present invention, please refer to the following detailed description and drawings related to the present invention, but the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

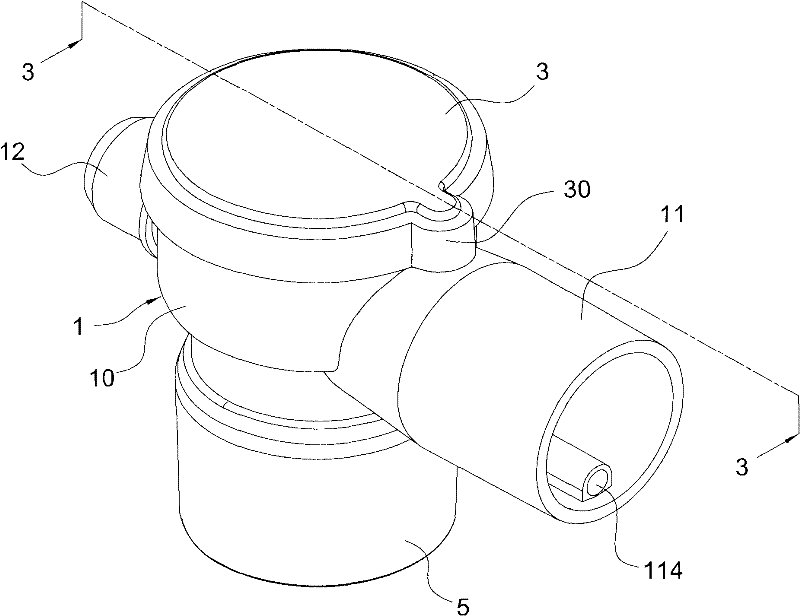

[0035] see figure 1 , figure 2 and image 3 , are respectively the three-dimensional exploded view, the three-dimensional combined view and the present invention figure 2 3-3 section cutaway view. The present invention provides a breathing tube control valve and a gas pipeline for connecting the control valve. The breathing tube control valve includes a housing 1, a valve part 2, and a cover 3; wherein:

[0036] The housing 1 is hollow, and has a cavity pipe 10, an air inlet pipe 11 and an air outlet pipe 12, and an inner pipe 100 is arranged in the chamber pipe 10, and an inner cavity 101 is formed in the inner pipe 100, which is connected with the air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com