Up-press domestic bean sprouting machine

A bean sprout machine and household technology, which is applied to the upper-pressure household bean sprout machine and the device field of self-cultivating bean sprouts at home, can solve the problems of compression spring corrosion, complicated structure, production cost of adding soybean sprout machine, etc., so as to reduce the overall manufacturing Cost, improve space utilization, simple and flexible product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

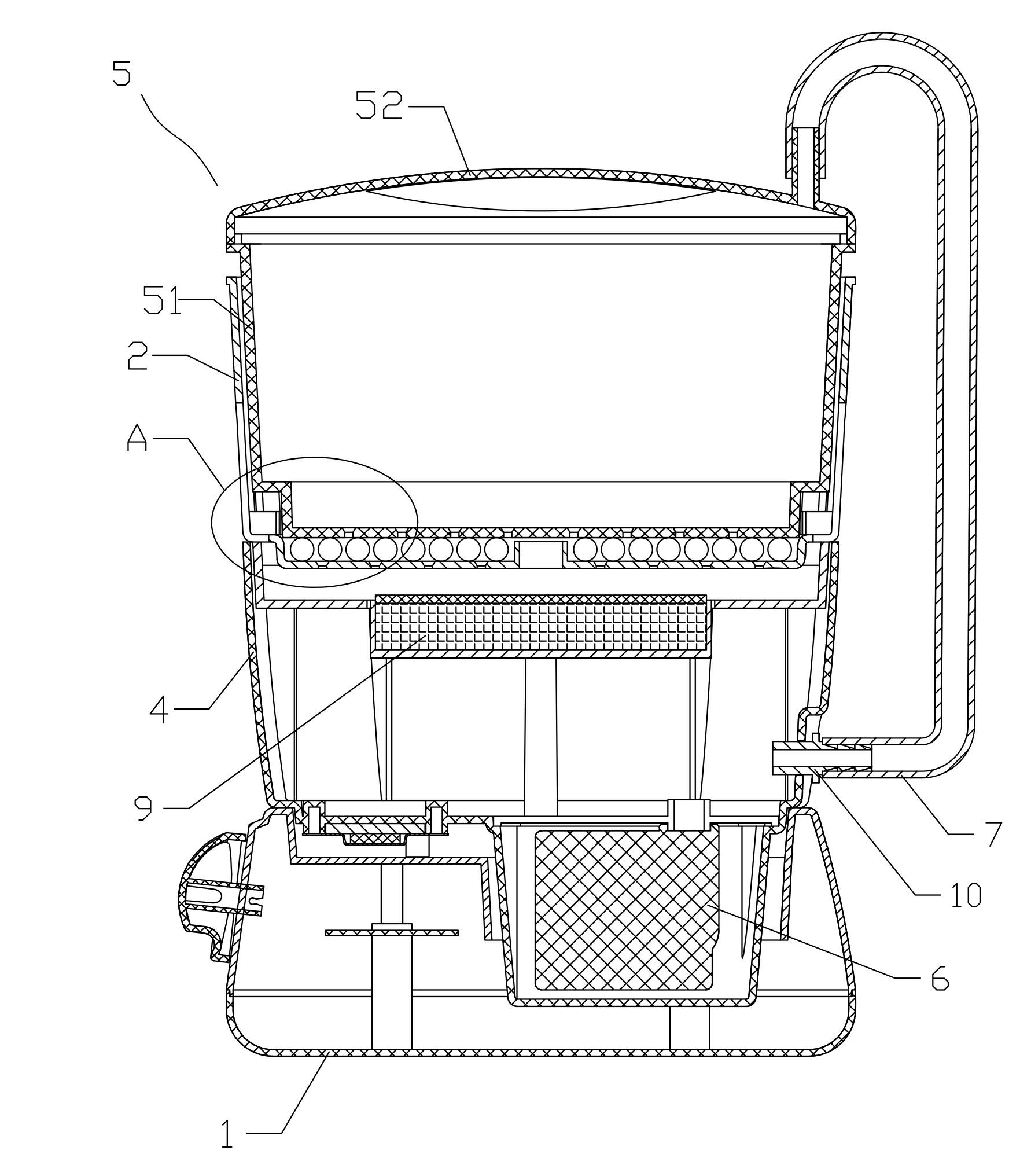

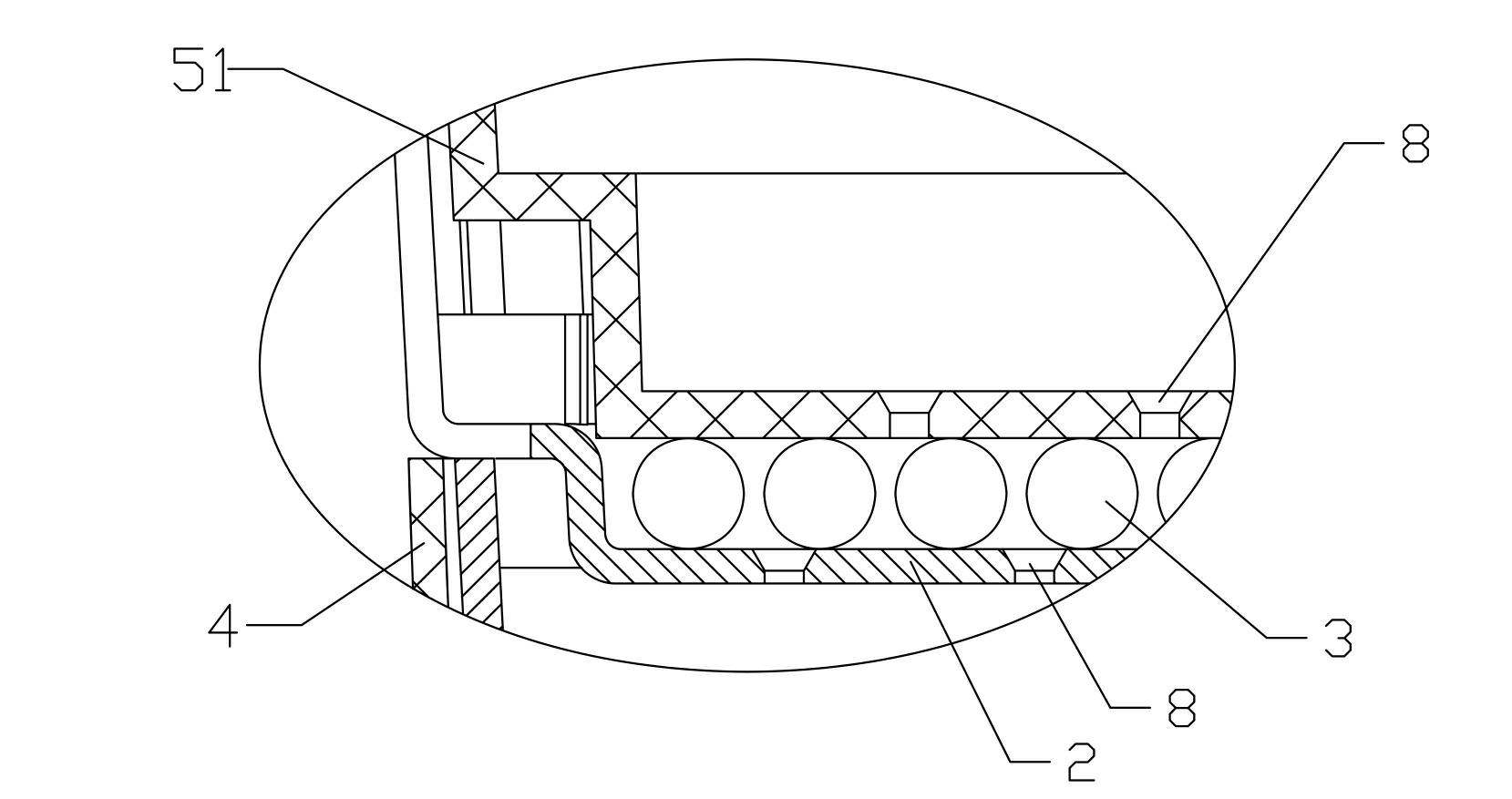

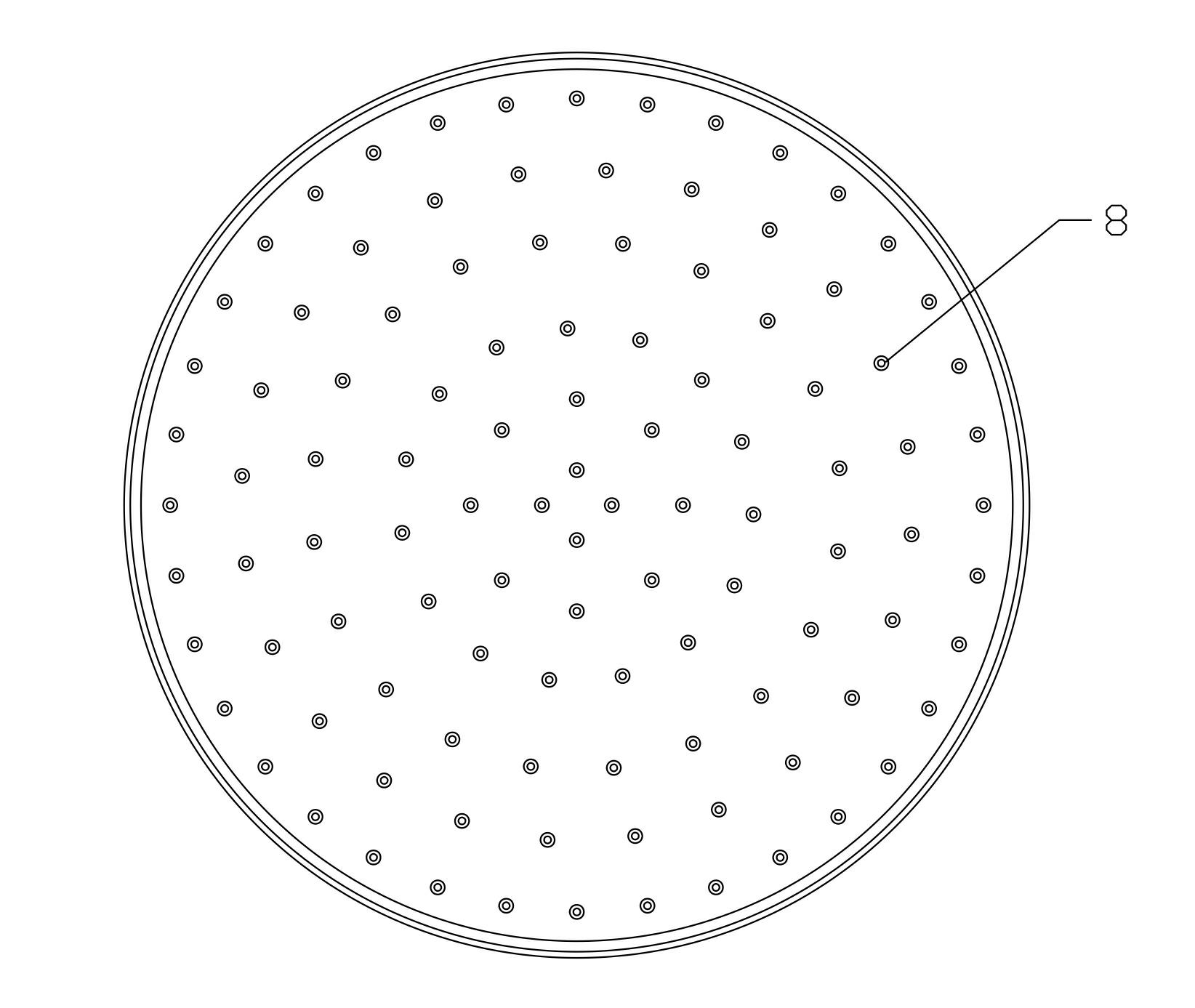

[0021] according to Figure 1 to Figure 3 As shown, it is the best embodiment of the present invention. The above-pressed household bean sprouts machine of the present invention includes a base 1 and a water storage tank 4 arranged on the base 1. The water storage tank 4 is provided with an inner cavity bottom wall for Cultivate the cultivation case 2 of bean sprouts seed 3, and water storage tank 4 is used for collecting and storing the water yield for showering bean sprouts that flows down from cultivation case 2 and filter case 4. During, the present invention improves on the structure basis of existing bean sprouts machine, is provided with the overhead water tank 5 that is used to be directly crimped on the inner cavity bottom wall of the cultivation case 2 above described cultivation case 2, that is to say, when During the cultivation of bean sprouts, the bean s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com