Internally modified substrate for epitaxial growth, crystal film-forming body, device, bulk substrate manufactured using same, and method for manufacturing them

A technology of epitaxial growth and manufacturing methods, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as the quality of nitride semiconductor films or the uniformity of light-emitting wavelengths, and achieve the goal of improving quality or yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

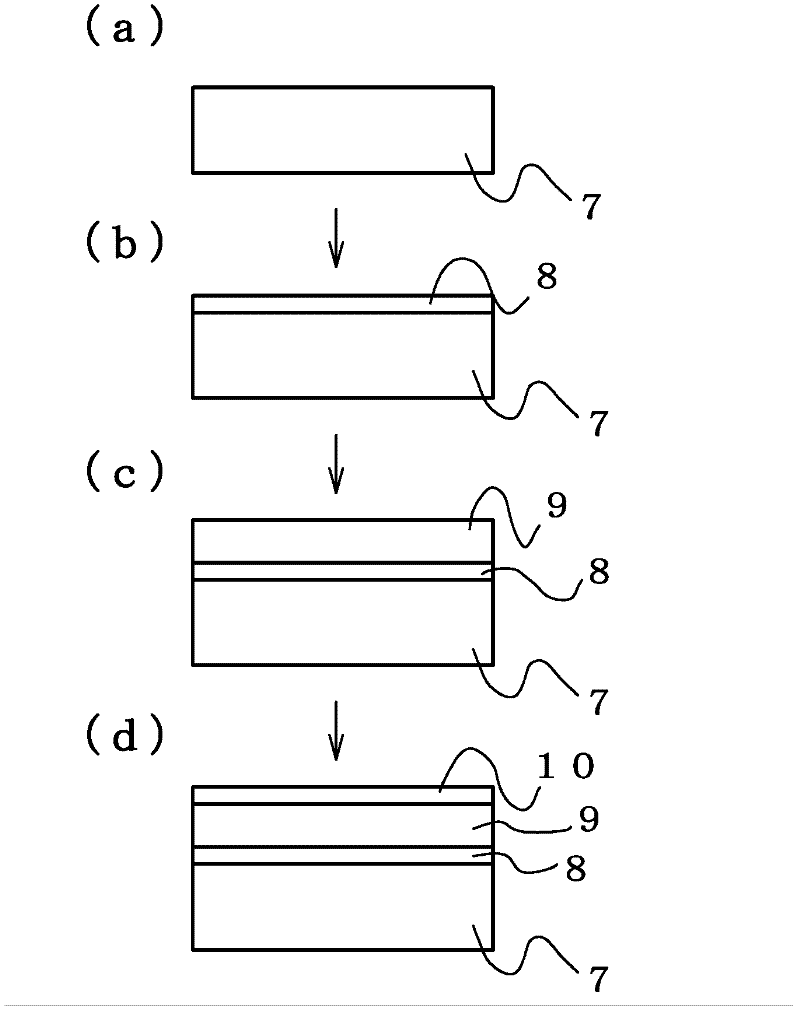

[0170] As the sapphire substrate for forming the modified region pattern, a 2-inch sapphire substrate whose one side was ground was used. The substrate thickness was 430 μm. The warpage shape and warpage amount of the substrate before the modified region pattern is formed are measured by a laser interferometer.

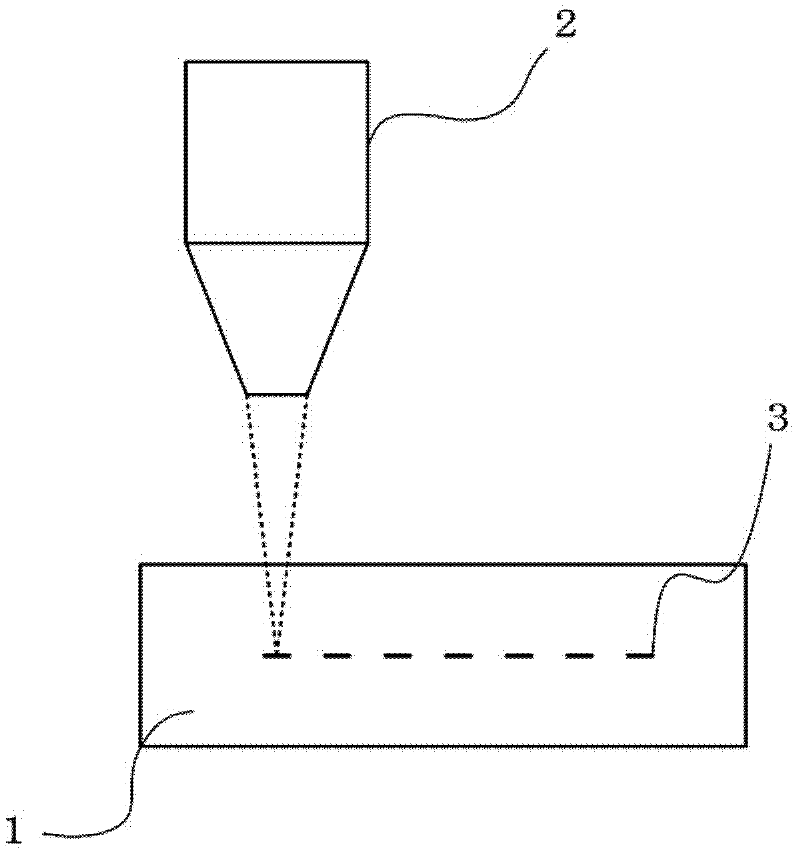

[0171] Next, the sapphire substrate was placed on the sample stage of the pulsed laser device, and the pattern of the modified region inside the sapphire substrate was formed.

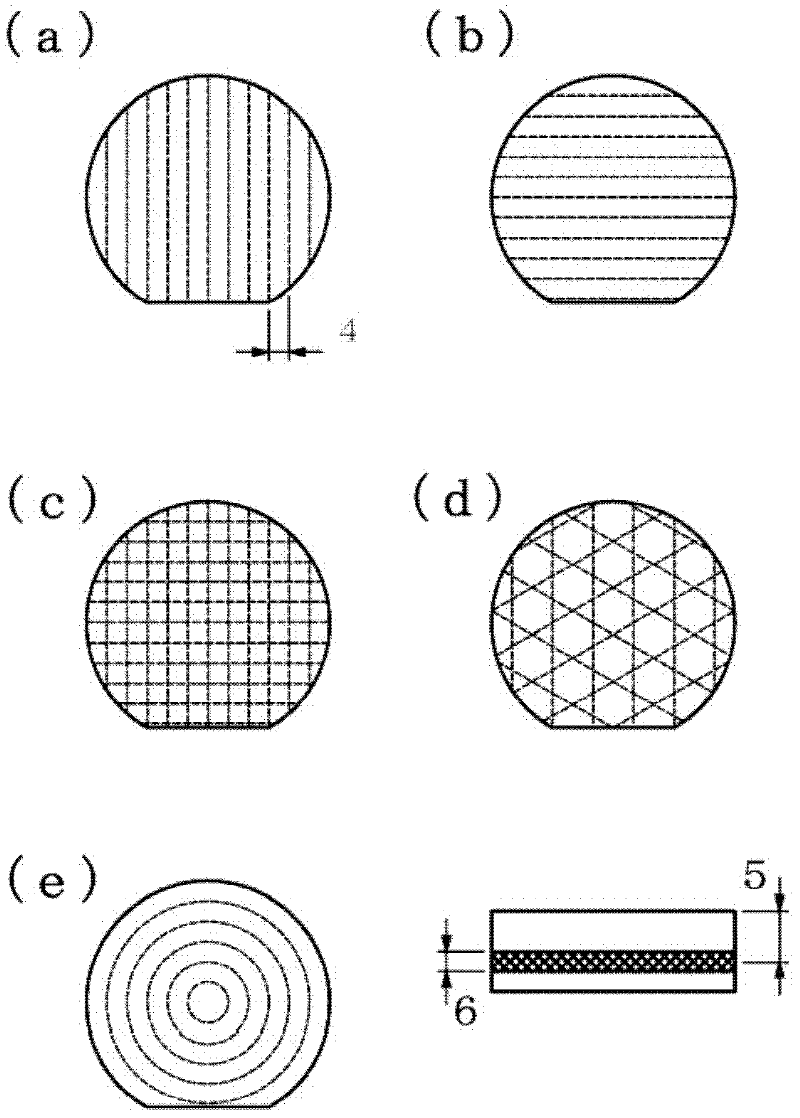

[0172] Table 3 shows the pattern shapes of samples 1 to 9, the distance between each line, the formation position, the length of the modified layer, and the processing time for each sheet. The substrate shape of the sapphire substrate after the modified area pattern is formed is measured by a laser interferometer, and the warpage and substrate thickness are measured by a linear gauge and a laser interferometer. In Table 3, ⊥O.F. means perpendicular to the orientation plane of the sapphire su...

Embodiment 2

[0179] As the sapphire substrate for forming the internal modified region pattern, a 4-inch sapphire substrate whose one side was ground was used. The substrate thickness was 650 μm. Similar to Example 1, the warped shape and warped amount of the substrate before the modified region pattern was formed were measured with a laser interferometer.

[0180]Next, the sapphire substrate was placed on the sample stage of the pulsed laser device, and the pattern of the modified region inside the sapphire substrate was formed. Table 5 shows the pattern shapes, pitches, and formation positions of samples 10 to 19.

[0181] [table 5]

[0182]

[0183] The warped shape of the substrate after the modified region pattern is formed is measured by a laser interferometer, and the warped amount is measured by a linear measuring instrument. Table 6 compares the substrate shape, warpage amount, and curvature calculated from the warpage amount before and after the modified region pattern is f...

Embodiment 3

[0188] Samples 10, 12, 14, 16, and 18 in the sapphire substrate on which the modified region pattern was formed in Example 2, and the existing sapphire substrate (as sample 20) without a pattern were simultaneously introduced into the MOCVD device , and the growth of the GaN layer on the sapphire substrate was carried out. Table 7 shows the growth temperature and film thickness in each film formation process.

[0189] [Table 7]

[0190] Growth temperature (℃)

Film thickness (nm)

AlGaN buffer layer

550

500

n-GaN layer

1070

5000

GaN / InGaN active layer

750

100 / 2

[0191] The In-situ (in-situ) observation results of each sample are shown in Figure 8a ~ Figure 8f In Table 8, the warped shape, warped amount, and curvature of the substrate of each sample are shown in Table 8, and the amount of change in substrate curvature in each step is shown in Table 9.

[0192] (1)~(4) in Table 9, such as Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com