Higher efficiency extraction and cooling system for heavy ash flows

A high-flow, heavy-ash technology, used in lighting and heating equipment, etc., can solve the problem of poor efficiency of electrostatic separators, and achieve the effect of effective preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

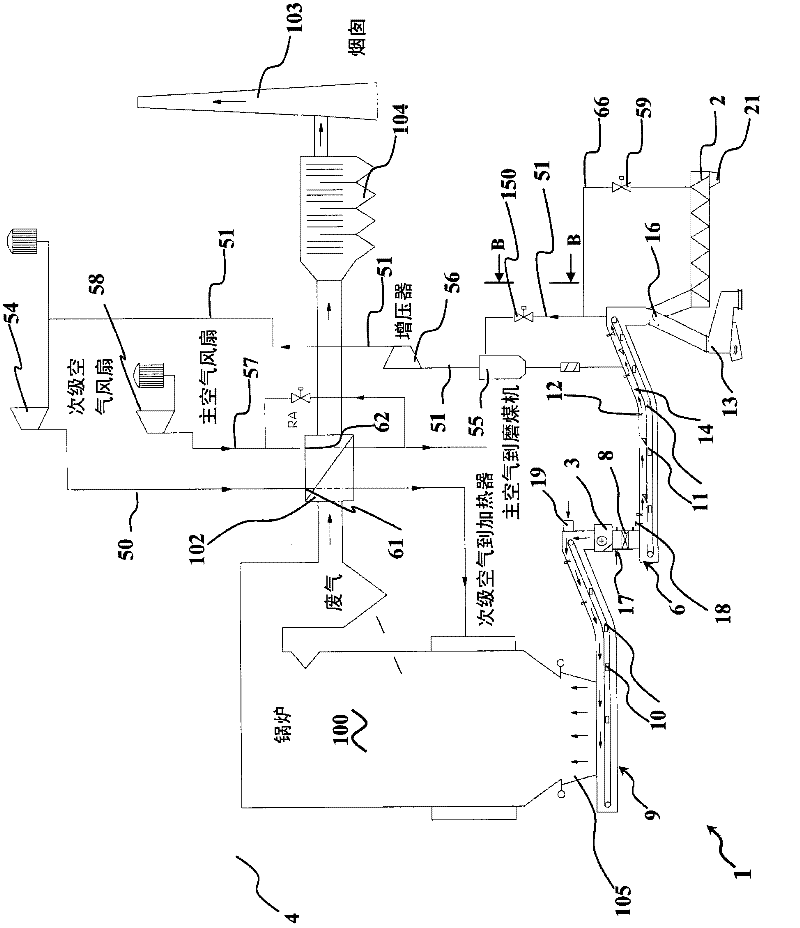

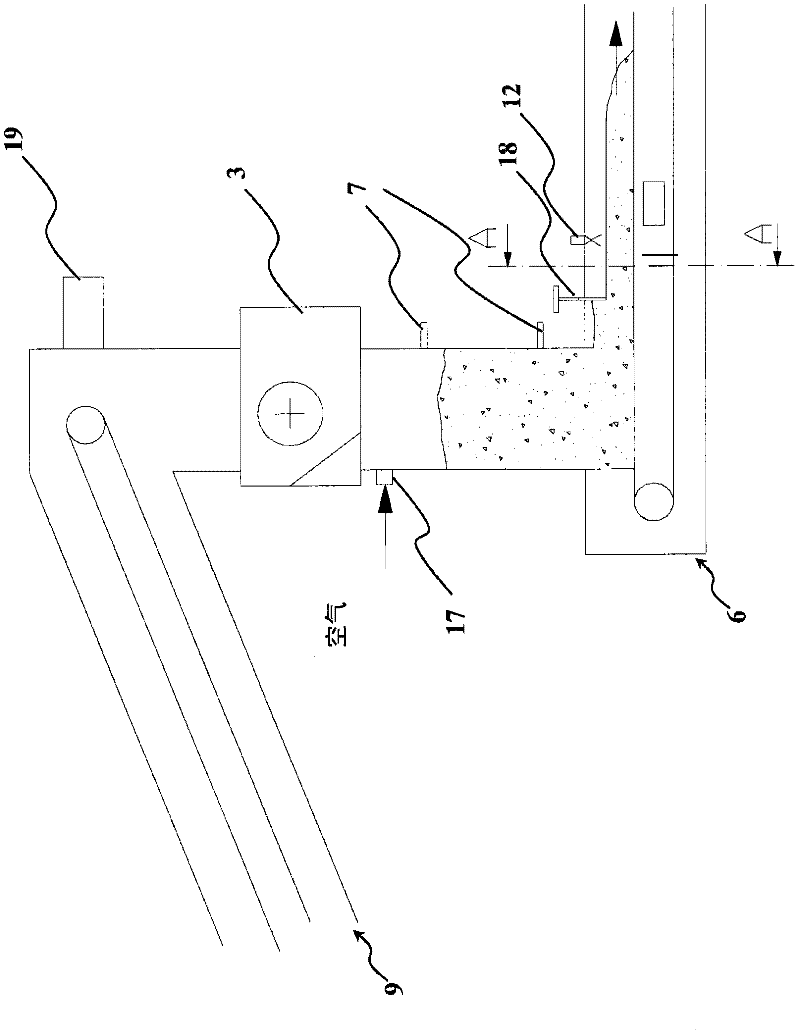

[0045] Referring to the above figures, an apparatus for extracting and cooling combustion residues, of the type used eg in thermal power plants of solid fossil fuels and according to a preferred embodiment of the present invention, is generally designated with reference numeral 1 . As will be better understood in the description below, the plant 1 is particularly suitable for handling high flows of heavy ash, eg resulting from the combustion of high ash content coal or lignite.

[0046] For greater clarity, the different parts of the plant 1 will be described below with reference to the path followed from the extraction of combustion residues from the bottom of the combustion chamber (or boiler) 100 until the residues are to be disposed of.

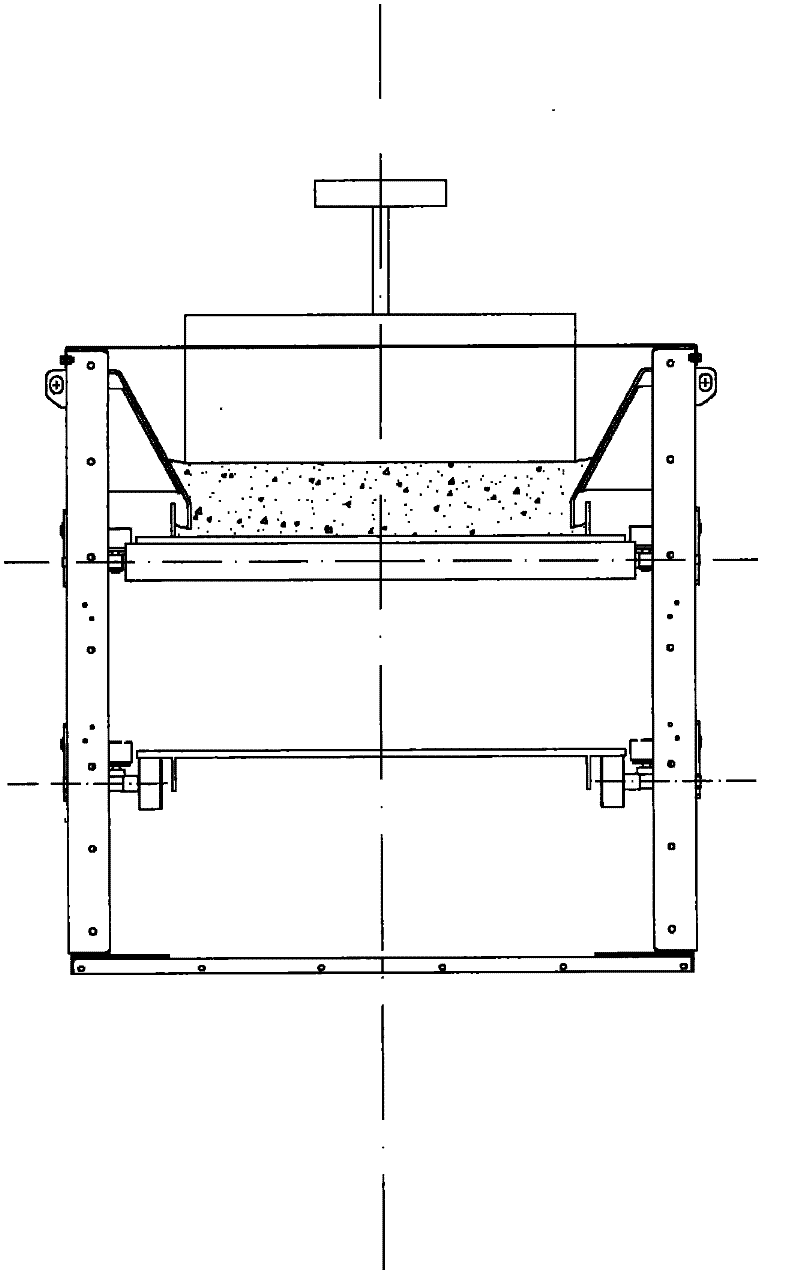

[0047] Downstream of the combustion chamber 100 , or better its transition funnel 105 , the plant 1 provides a first extraction and / or transport unit, in particular a dry extractor 9 mainly made of high thermal resistance steel. Said extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com