Repeated adaptive grouting system and construction method

A grouting system and self-adaptive technology, applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as large sleeve valve pipe diameter, affecting the bearing capacity of anchor bolts, and loss of effective cross-sectional area of anchor bolts and anchors , to achieve the effect of wide application range, simple production and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

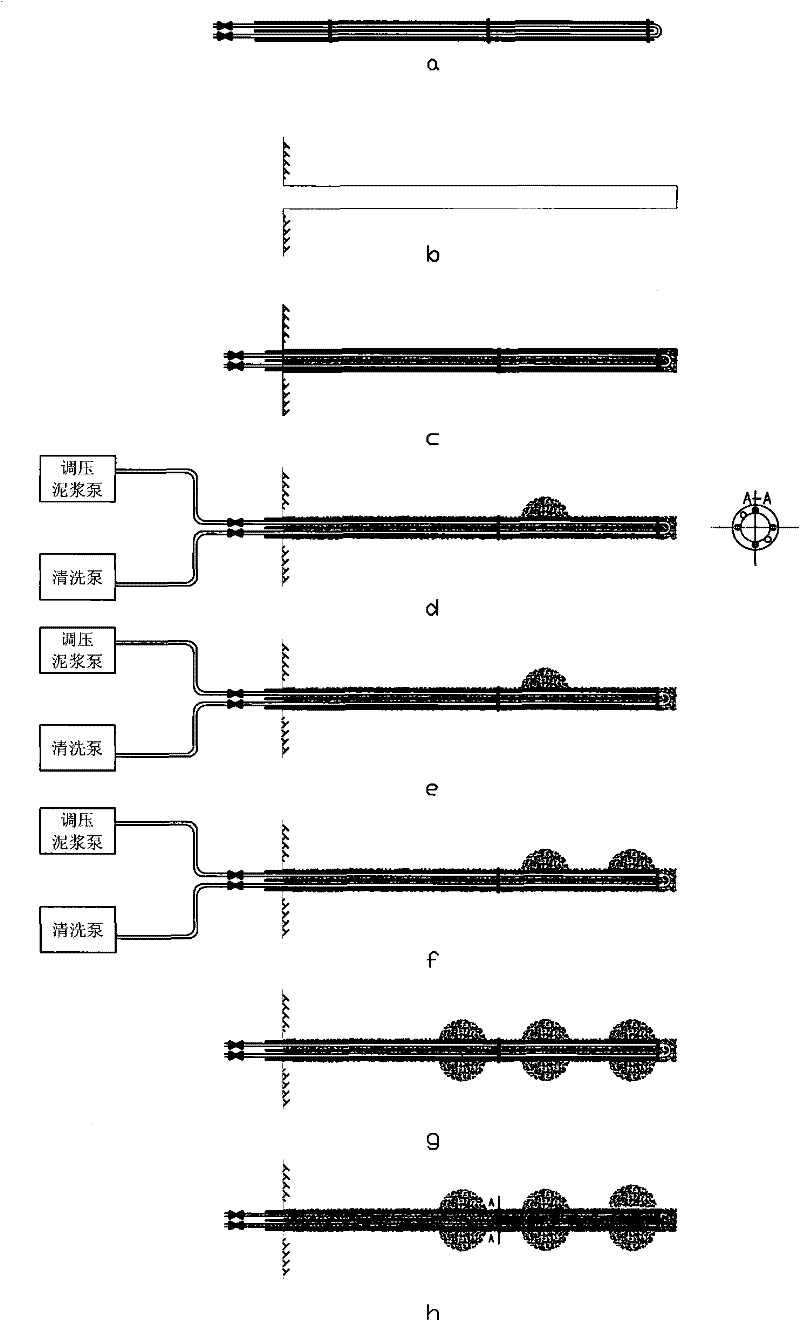

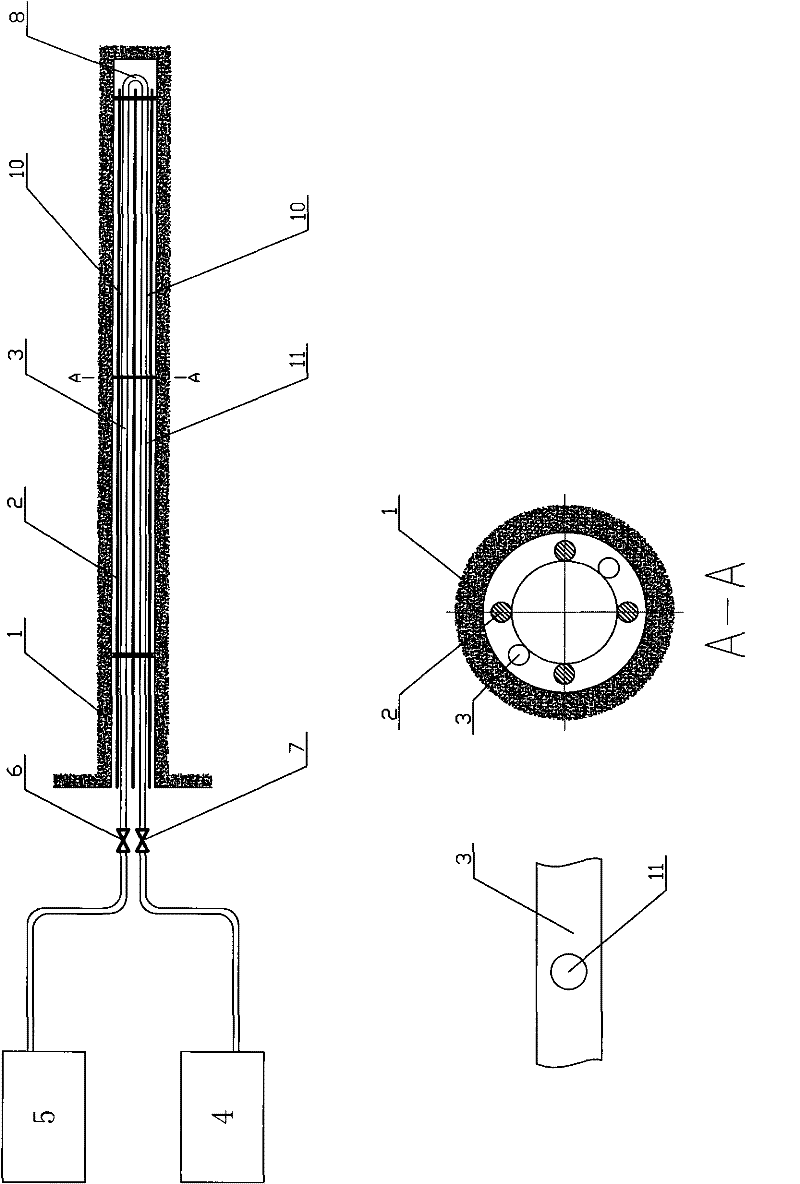

[0055] A specific implementation method of a repetitive self-adaptive grouting system and construction process, the basic steps are as follows:

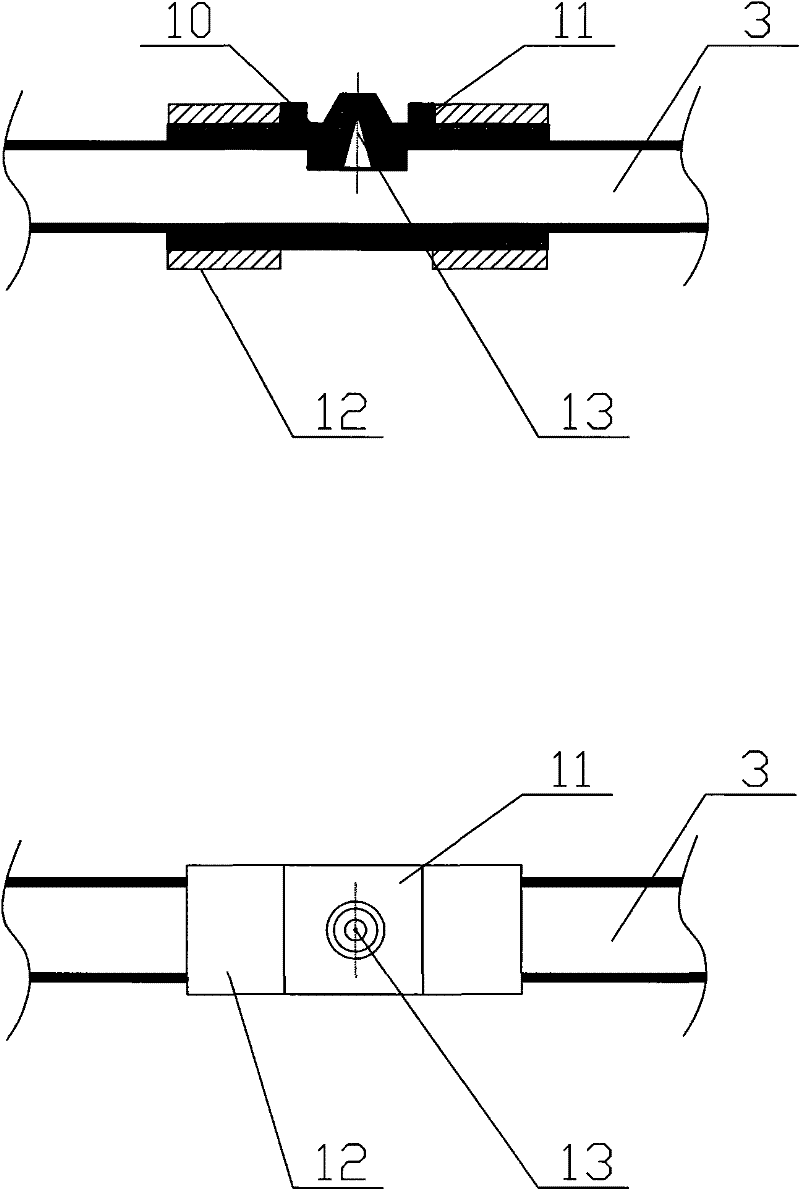

[0056] 1. If figure 1 , 2 As shown in , 3, two 19m ordinary galvanized pipes with an outer diameter of 22mm and an inner diameter of 18mm are used as split grouting pipes. The maximum diameter of the flexible pressure opening valve is 4mm. The same 30mm grouting pipe is used to make a U shape with a bending machine. The diameter of the U shape is 60mm, and it is placed at the bottom of the U shape. Set a grouting port with a diameter of 8mm, install a flexible pressure opening valve, connect the U-shaped pipe with the two sections of the grouting pipe respectively to form a long U-shaped pipe, and keep the distance between the straight pipe sections of the grouting pipe greater than 60mm. Two valves are installed respectively for pressure grouting and grouting pipe cleaning. After the grouting pipe is manufactured, it is fixed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com