A method for extracting cantharidin with compound enzyme

A cantharidin and compound enzyme technology, which is applied in the fields of drug combination, sexual diseases, organic chemistry, etc., to achieve the effect of convenient follow-up processing, less product impurities, and increased white blood cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

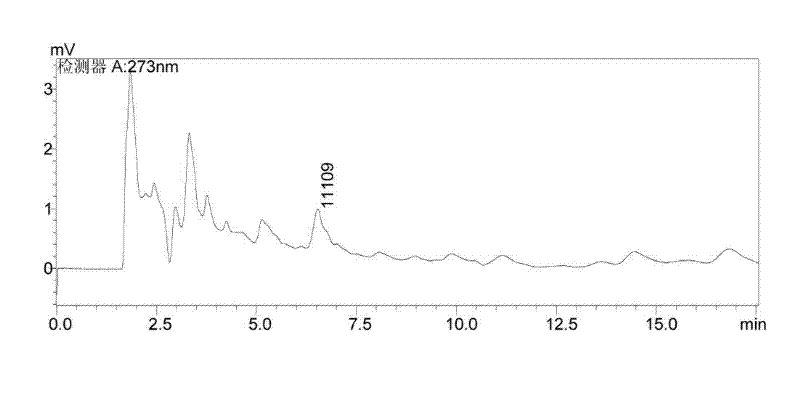

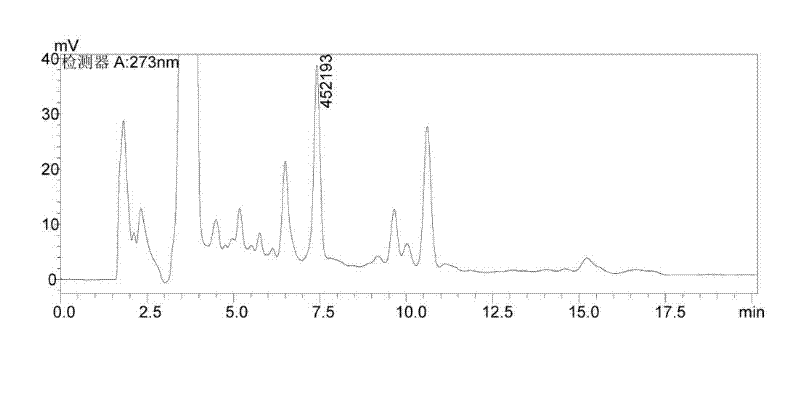

Image

Examples

Embodiment 1

[0031] (1) Take the southern big mylabris ( Mylabris phalerata Pallas ) 500g of medicinal materials, pulverized and passed through a 10-20 mesh sieve.

[0032] (2) Soak with water, add 0.8g of cellulase and 1.6g of pectinase per 500g of medicinal materials.

[0033] (3) Adjust the pH to 5.0 with HCl, enzymatically hydrolyze at 50°C for 2.5 hours, and then boil for 3 minutes to inactivate the enzyme.

[0034] (4) Extract the enzymatic hydrolysis product with chloroform-absolute ethanol-concentrated hydrochloric acid (volume ratio 1.5:1:1) in a 66°C water bath for 24 hours, filter the extraction product with hot suction, and add chloroform- Absolute ethanol-concentrated hydrochloric acid (volume ratio 1:2:1) leaching, hot suction filtration.

[0035] (5) The two filtrates were combined and evaporated to dryness, the obtained solid was dissolved in water-chloroform (volume ratio 2:1), and the lower organic phase was extracted.

[0036] (6) Rotate the lower organic phase to dry...

Embodiment 2

[0039] (1) Take 500g of Chinese mylabris medicinal material, crush it, and pass it through a 10-20 mesh sieve.

[0040] (2) Soak with water, add 1g of cellulase and 1.8g of pectinase per 500g of medicinal materials.

[0041] (3) Adjust the pH to 5.8 with HCl, enzymatically hydrolyze at 48°C for 3 hours, and then boil for 4 minutes to inactivate the enzyme.

[0042] (4) Extract the enzymatic hydrolysis product with chloroform-absolute ethanol-concentrated hydrochloric acid (volume ratio 1.5:1.5:1) in a water bath at 57°C for 23 hours, filter the extracted product with hot suction, and add chloroform- Absolute ethanol-concentrated hydrochloric acid (volume ratio 1:2:1.5) leaching, hot suction filtration.

[0043] (5) The two filtrates were combined and evaporated to dryness, the obtained solid was dissolved in water-chloroform (volume ratio 2:1.5), and the lower organic phase was extracted.

[0044] (6) Rotate the lower organic phase to dryness, add absolute ethanol-petroleum ...

Embodiment 3

[0047] (1) Take yellow and black mylabris ( M. cichorii Linnaeus ) 500g of medicinal materials, pulverized and passed through a 10-20 mesh sieve.

[0048] (2) Soak with water, add 1.5g of cellulase and 2.0g of pectinase per 500g of medicinal materials.

[0049] (3) Adjust the pH to 6.0 with HCl, enzymatically hydrolyze at 45°C for 2.5 hours, and then boil for 2 minutes to inactivate the enzyme.

[0050] (4) Extract the enzymatic hydrolysis product with chloroform-absolute ethanol-concentrated hydrochloric acid (volume ratio 1.5:1:1) in a 70°C water bath for 25 hours, filter the extracted product with hot suction, and add chloroform- Absolute ethanol-concentrated hydrochloric acid (volume ratio 1:2:1.5) leaching, hot suction filtration.

[0051] (5) The two filtrates were combined and evaporated to dryness, the obtained solid was dissolved in water-chloroform (volume ratio 2:1.5), and the lower organic phase was extracted.

[0052] (6) Rotate the lower organic phase to dryn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com