Water-permeable electrochemical microbial reaction walls and methods of use thereof

A microbial reaction and electrochemical technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of increased remediation costs, exhausted reactants, and must be replaced. To achieve the effect of reducing the cost of remediation and improving the effect of pollution control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

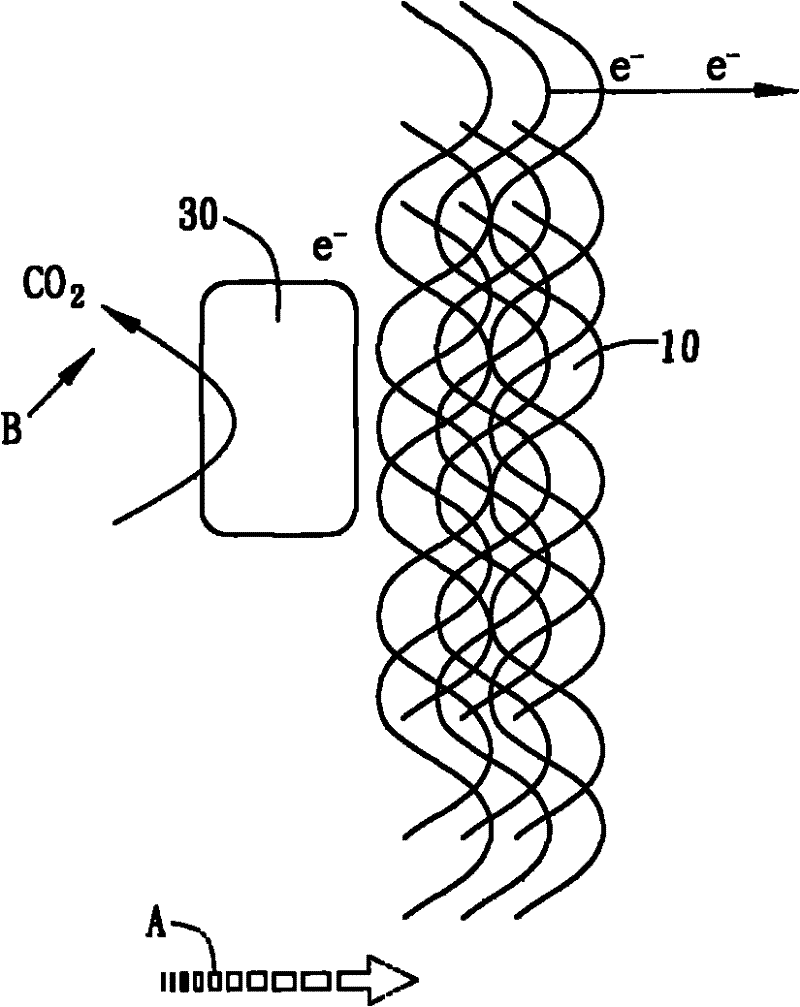

[0031] Embodiment 1: In-situ (on-the-spot) microbial decomposition efficacy test (with electrodes as electron acceptors)

[0032] In this embodiment, benzene is used as the target organic pollutant (concentration is about 350ppm), and the compound microorganisms of polluted soil are used as the source of planting bacteria. In the reaction bottle, the degradation and bioelectric current generation tests are carried out, and the applied voltage is 0.2V vs.Ag / After AgCl, during the experiment, it can be observed that the surface of conductive activated carbon fibers is gradually coated with biofilm.

[0033] The correlation between the presence of benzene and the bioelectric current is as follows: Figure 4 shown. After adding 140ppm of benzene at the beginning of the experiment ( Figure 4 As shown by arrow a), there is no instantaneous current generation (showing that benzene is not directly oxidized by the electrode), and then the current gradually increases, the highest va...

Embodiment 2

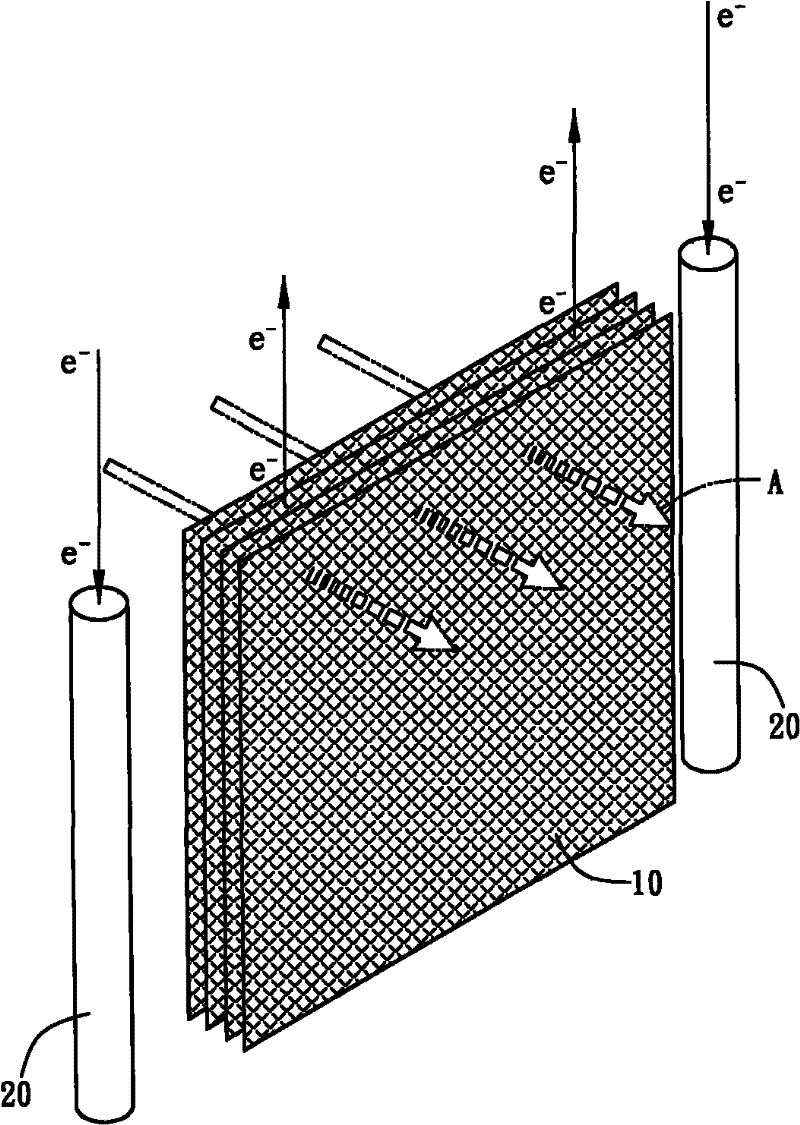

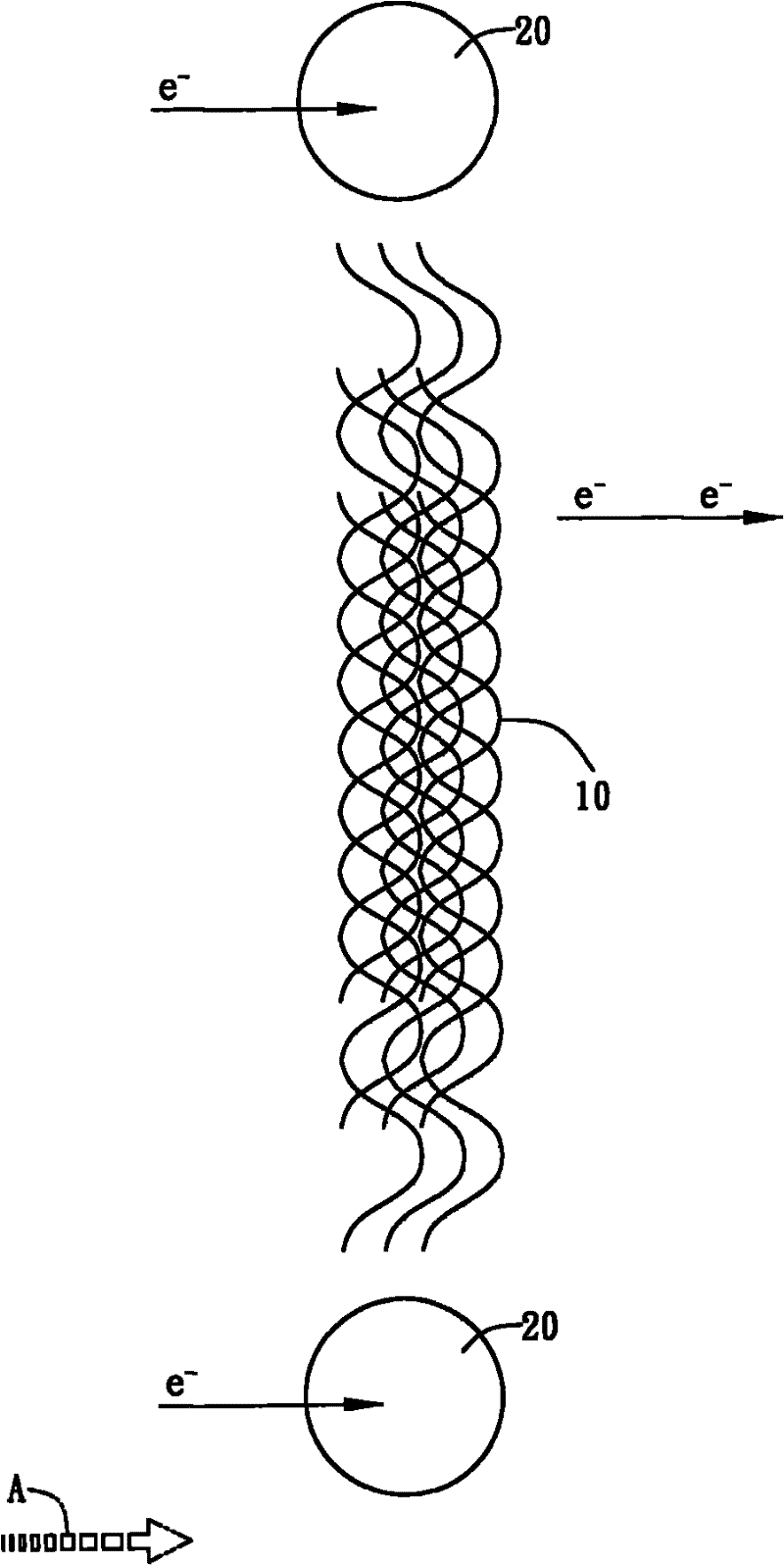

[0035] Example 2: Verification experiment of a simulated soil pipe column of a permeable electrochemical microbial reaction wall

[0036] Embodiment two is to carry out the simulation test of the permeable electrochemical microbial reaction wall with soil pipe column in the laboratory, the soil pipe column in the present embodiment is 45 centimeters long, and internal diameter is 3 centimeters, and it comprises one deck conductive activated carbon fiber layer ( Thickness 15 centimeters) and a platinum (Pt) cathode, it is arranged on the adjacent side distance of this conductive activated carbon fiber layer at a distance of 5 centimeters, the experimental process is carried out in a continuous flow mode, and the hydraulic retention time is within 2 days. The simulated pollutants contained in the influent solution are benzene, toluene, ethylbenzene, and p-xylene (BTEX for short), and the test concentrations are about 19524, 15383, 14981, and 7257 ppb, respectively, which are take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com