An Arrayed Electrohydrodynamic Jet Printing Head

A print head, electro-fluid technology, applied in printing and other directions, can solve the problems of inability to eject high-viscosity ink, inability to print sub-micron sized patterns, complicated nozzle manufacturing process, etc., to facilitate industrial application, omit manufacturing process, save money effect of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The arrayed electrohydrodynamic inkjet printing head of the present invention adopts the principle of electrohydrodynamic inkjet printing, and realizes the breakage of the jet by controlling the voltage, thereby generating ink droplets to form a jet, which flows out from the nozzle to realize inkjet printing.

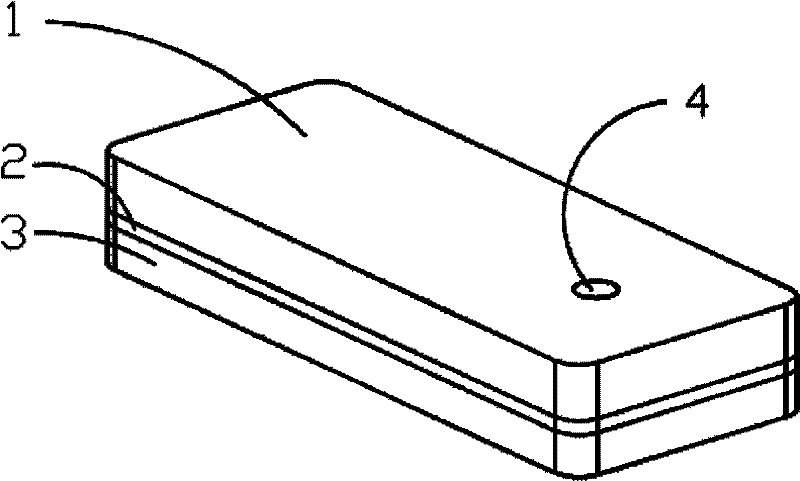

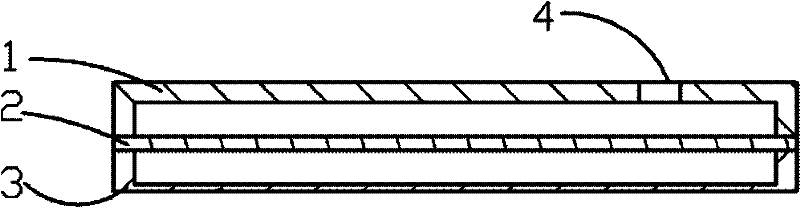

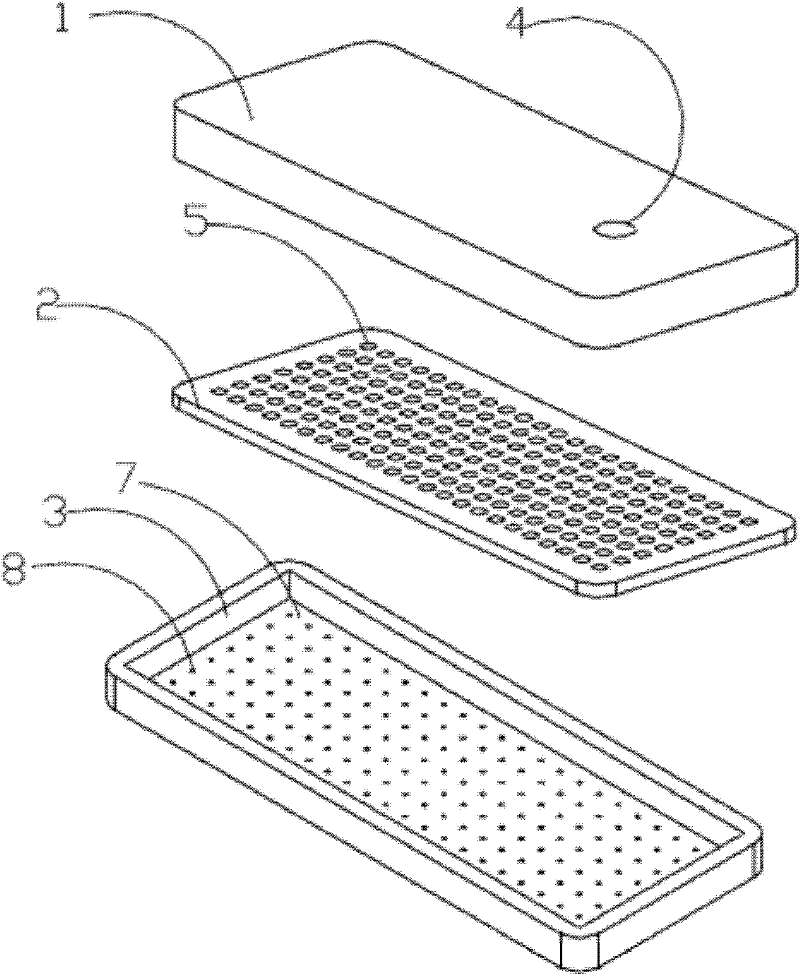

[0028] Such as Figure 1~4 As shown, the printing head includes an ink cartridge 1, and a nozzle plate 2 located in the middle of the ink cartridge that divides the inner chamber of the ink cartridge into an upper chamber and a lower chamber, wherein the nozzle plate 2 is provided with nozzle holes 5 arranged in an array, Each nozzle hole 5 runs through the upper chamber and the lower chamber, and the bottom surface of the lower part of the ink cartridge 1 is provided with corresponding ink outlets 8 arranged in an array...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com