Steady frame of a machining cutting machine tool

A technology for cutting machine tools and steady rests, which is applied to metal processing machine parts, metal processing equipment, manufacturing tools, etc. It can solve the problems of difficult adjustment of force, loose force of the workpiece, and locking, so as to achieve uniform force and reduce The effect of being locked and beneficial to processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

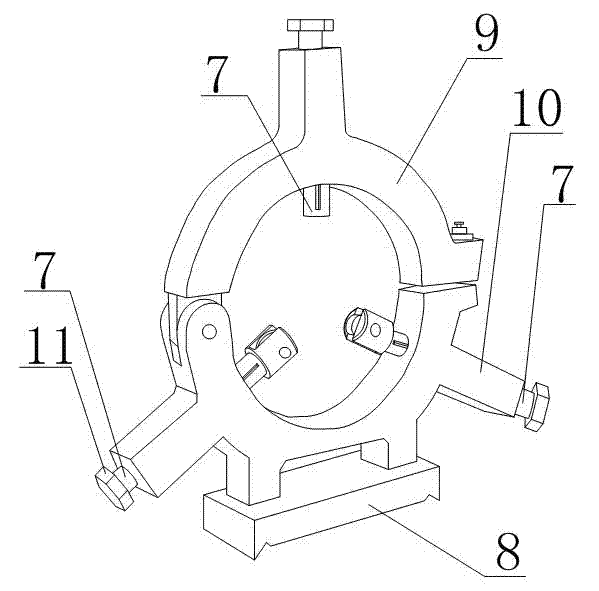

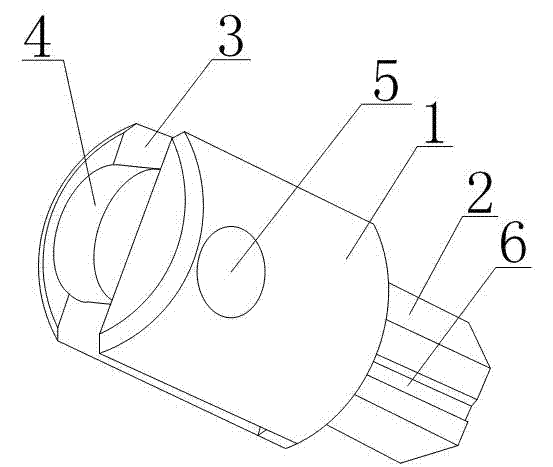

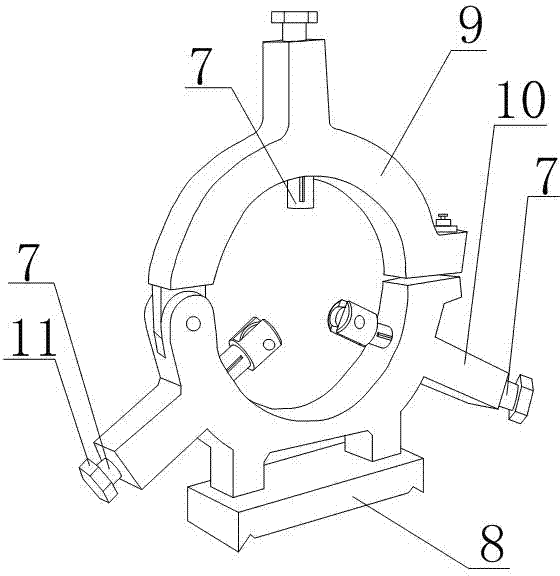

[0018] Such as Figures 1 to 2 As shown, the center frame of a machining and cutting machine tool of the present invention includes a mounting seat 8, a center frame body 9 is arranged on the mounting seat 8, three adjustment cylinders 10 are arranged on the center frame body 9, and three adjustment cylinders 10 are arranged on the adjustment cylinder 10. There is a turntable 11, and the turntable 11 is connected with the top wheel through the screw rod 7 in the adjustment barrel 10. The adjustment barrel 10 runs through the center frame body 9, and one end of the three adjustment barrels 10 located in the center frame body 9 is equipped with a top wheel. The top wheel includes The top cylinder 1, the top cylinder 1 is cylindrical as a whole, and one end surface of the top cylinder 1 is connected with a hexagonal column socket 2, and the socket 2 is provided with a guide groove 6 parallel to the axis of the top cylinder 1. The adjustment cylinder 10 is provided with a guide ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com