A variable flow electromagnetic low pressure mold filling method for aluminum alloy melt

An aluminum alloy melt and variable flow technology, applied in the field of metal casting, can solve the problems of reducing the quality of castings, entrainment, splashing, etc., and achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

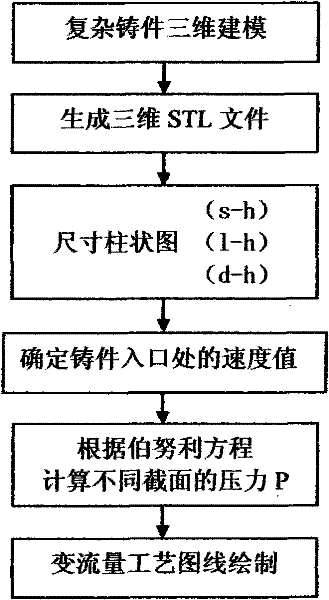

Method used

Image

Examples

Embodiment Construction

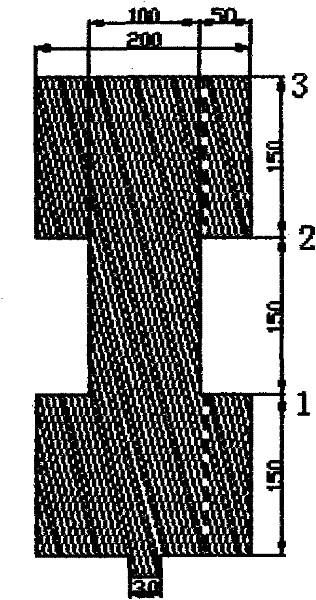

[0063] Take the I-shaped casting as a design example:

[0064] (1) CAD drawing of I-shaped casting

[0065]

[0066] figure 2 I-shaped casting CAD drawing

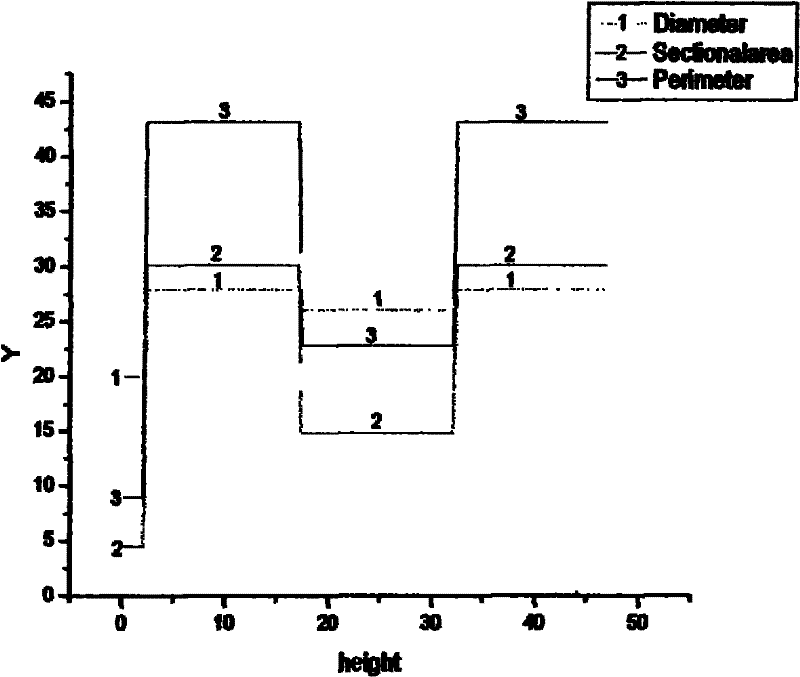

[0067] (2) The relationship between the cross-sectional area and height of the casting

[0068] Calculate and draw the histogram through the three-dimensional STL file of the I-shaped casting. like image 3 As shown, the four sets of data respectively represent: the X-axis is the vertical height of the casting from filling to different positions, 1 is the equivalent diameter corresponding to each height, 2 is the cross-sectional area, and 3 is the peripheral length.

[0069]

[0070] image 3 I-piece histogram

[0071] (3) Calculation of filling pressure of traditional craft I-shaped parts

[0072] Traditional process filling pressure calculation:

[0073] P 充 =μρgH=1.27×2400×9.8×0.45=13441Pa

[0074] It can be seen that although the I-shaped castings have cross-sectional changes at different heights, this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com