Wire storage conveyor

A conveyor and linear technology, applied in the field of linear material storage conveyors, can solve the problems of inability to prevent pollution, inconsistent length of outgoing wires, and easy work fatigue, etc., and achieve the effect of avoiding waste of wire materials, low working intensity, and not easy to fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below, the present invention will be further described in conjunction with the accompanying drawings, but the present invention is not limited thereto.

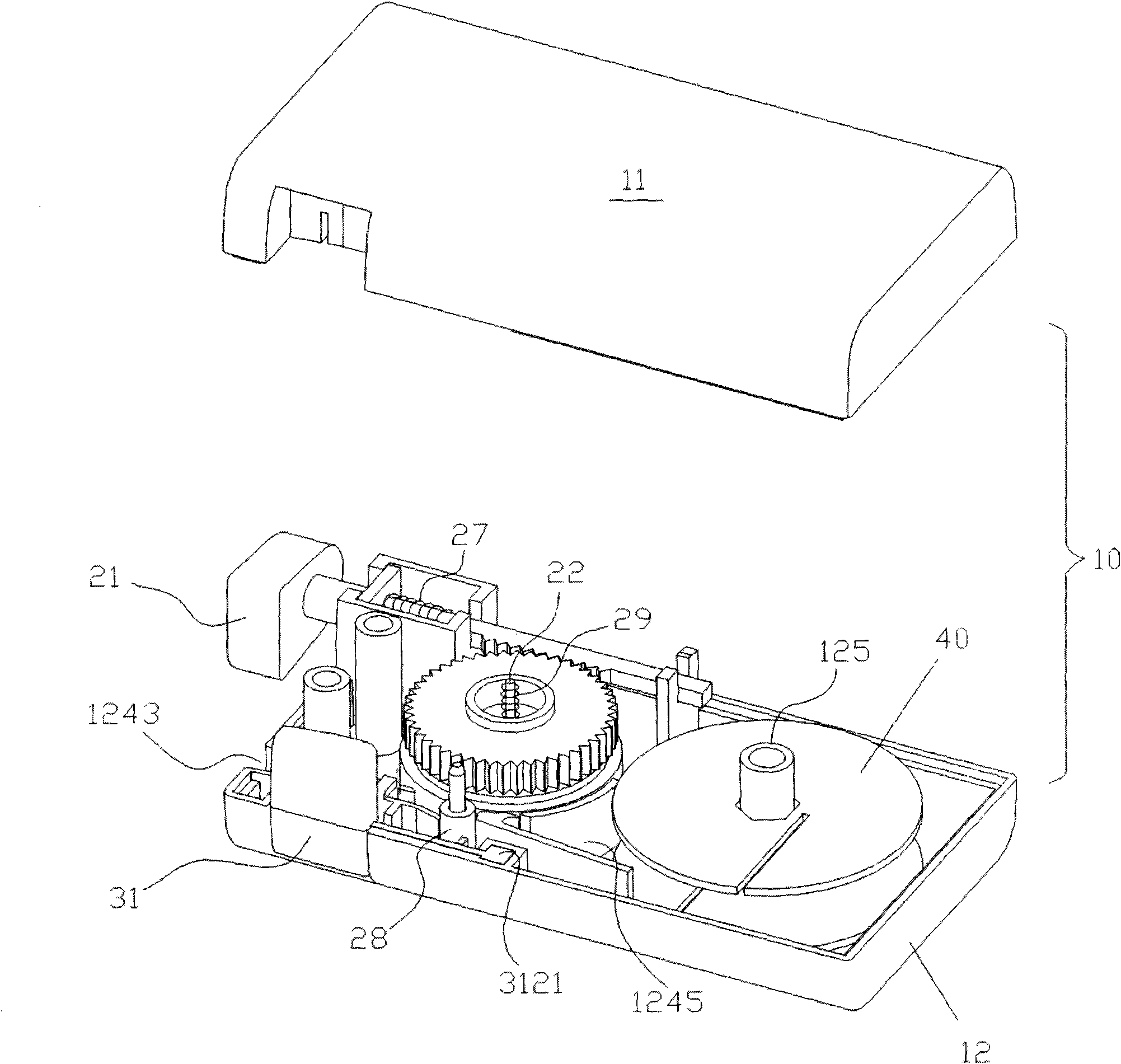

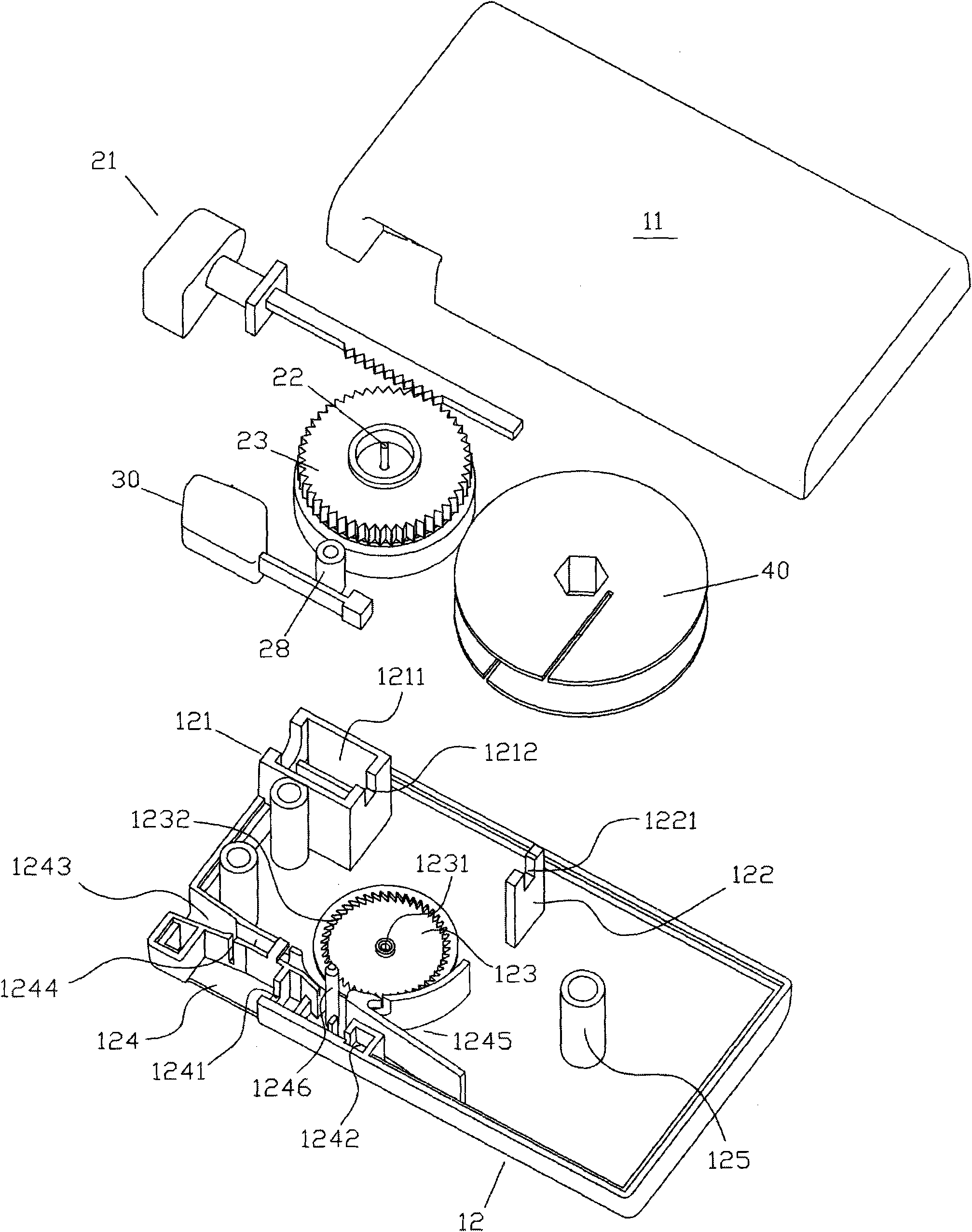

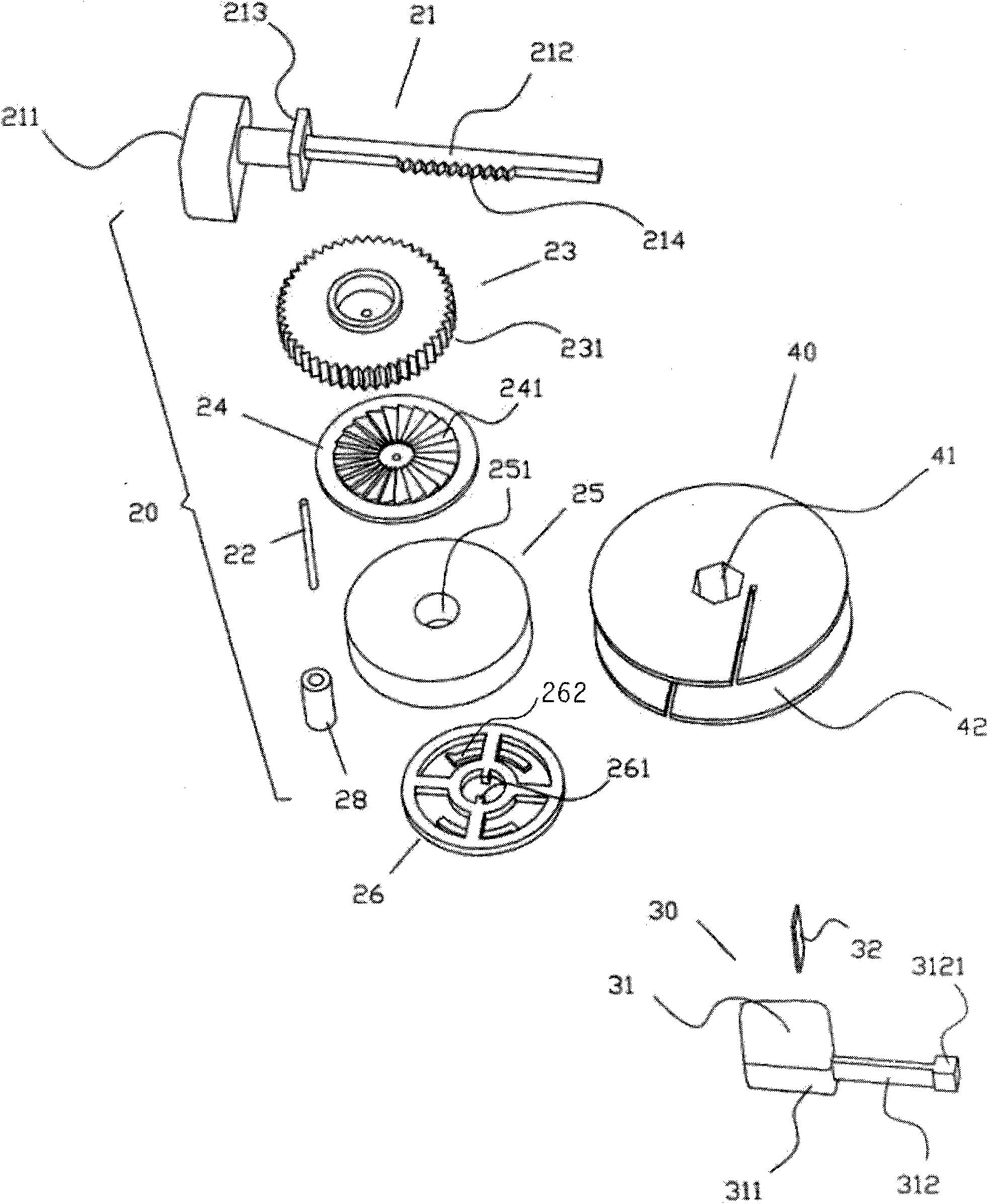

[0040] see figure 1 and combine Figure 2 to Figure 5 As shown, a wire material storage conveyor (100) is composed of a drive mechanism (20), a thread cutting mechanism (30) and a wire storage wheel (40) covered by a casing (10), wherein:

[0041] The casing (10) includes an upper casing (11) and a lower casing (12);

[0042] see figure 2 As shown, the upper shell (11) and the lower shell (12) are a corresponding structure that is fastened together, so that in the embodiment of the present invention, only the lower shell (12) is used as an example for specific description, and the lower shell ( 12) Contains a raised rectangular portion (121), a raised portion (122) and a positioning portion (123) for installing the main shaft (22), as well as a recessed groove (124) of the device thread cutting mechanism (30) and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com