Coating composition for frozen desserts

A technology for coating composition and frozen desserts, which can be applied in frozen desserts, food science, confectionery, etc., and can solve problems such as increased coating volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

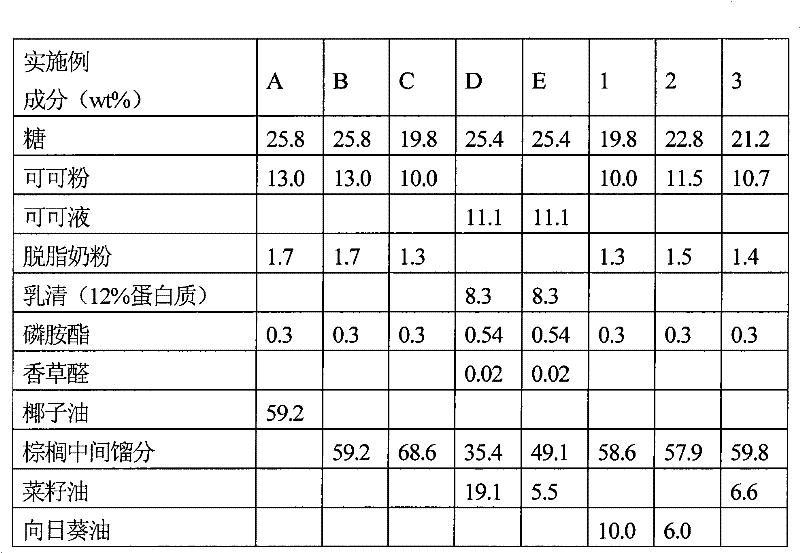

[0041] Coating compositions were prepared according to the formulations in Table 1. Examples A-E are comparative examples, and Examples 1-3 are examples according to the present invention. The palm middle distillate used was Creamelt 700 obtained from Loders Croklaan. Cocoa powder and cocoa liquor contain 10-12% and 55% cocoa butter, respectively.

[0042] Table 1

[0043]

[0044] Coatings were prepared in 1.5 kg batches as follows. First, an emulsifier was added to the oil at 45°C. Blend the dry ingredients together, then add half of the fat / emulsifier mixture to form a slurry. The slurry was placed in a laboratory scale ball mill (supplied by Leatherhead Food RA) which was run at about 60 rpm. Balls (equal volumes of balls with diameters of 9 mm, 11 mm, 14 mm and 17 mm) at a temperature of 50°C. The slurry was ground and the particle size was measured periodically with a Draper external digital micrometer. Once the particle size was reduced to less than 23 microns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com