Online detection method of printing machine based on machine vision

A detection method and machine vision technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of inability to guarantee the detection quality, high labor intensity, visual fatigue, etc., and achieve the effect of avoiding repetition, fast response, and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

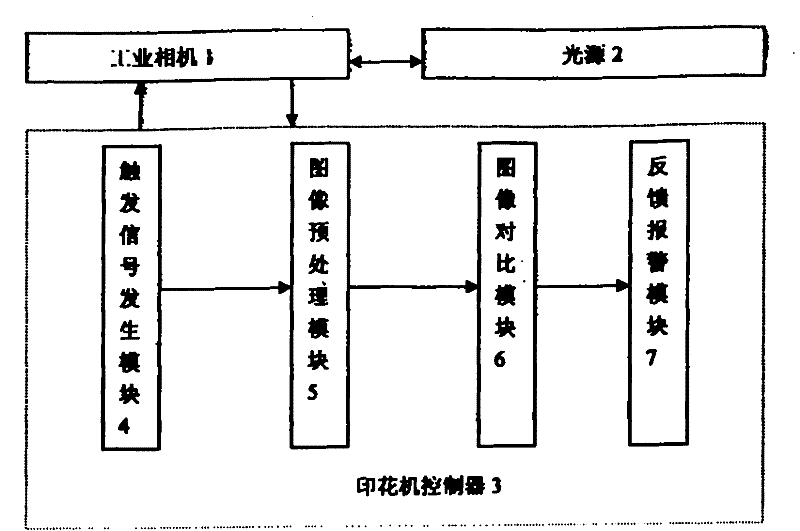

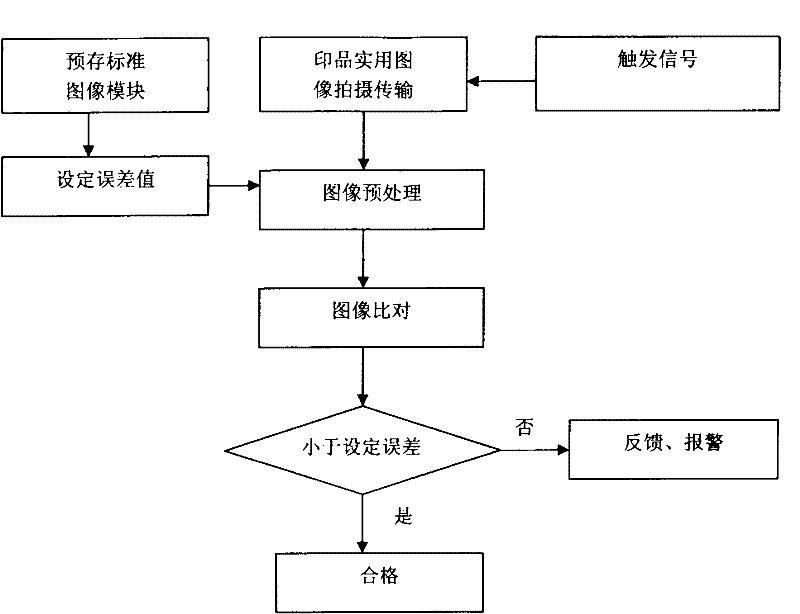

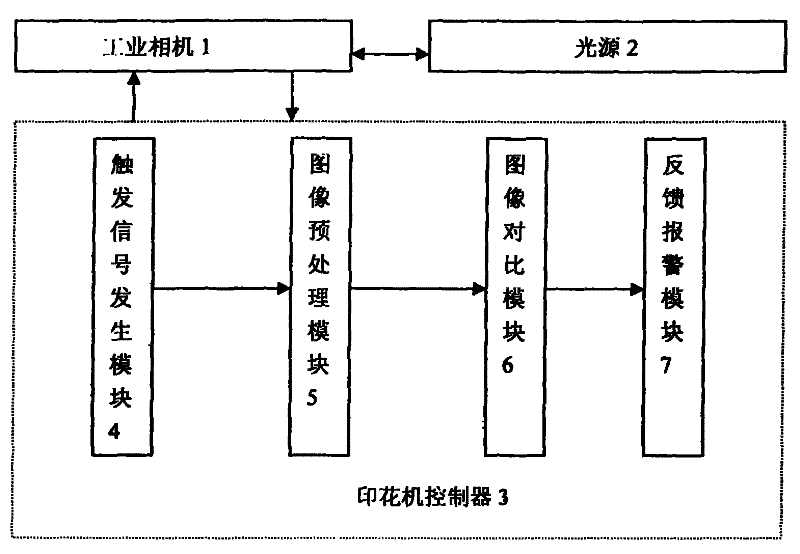

[0018] Such as figure 1 As shown, the hardware part is composed of an industrial camera 1, a light source 2, and a printing machine controller 3. The industrial camera of this embodiment adopts In-Sight1403C of Cognex Company, with a resolution of 1600×1200, capable of high-resolution inspection of various color applications. The light source is a ring light that surrounds the camera. The control system is built into the printing machine controller and consists of trigger signal generation module, image template pre-storage module, ingested image preprocessing module, image comparison module, feedback alarm and other modules. Such as figure 2 The flow chart of online detection is shown, and the following is a detailed description of the process.

[0019] 1. The pattern determined during plate making is stored in the printing machine controller as a standard image template;

[0020] 2. Set the allowable value of the defect area and image grayscale error;

[0021] 3. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com