Preparation device and application of thin tape elastic body

A technology for preparing a device and a projectile, applied in the field of testing, can solve the problem that manufacturers and users cannot detect and other problems, and achieve the effects of fast measurement work, low preparation cost, and simple measurement technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

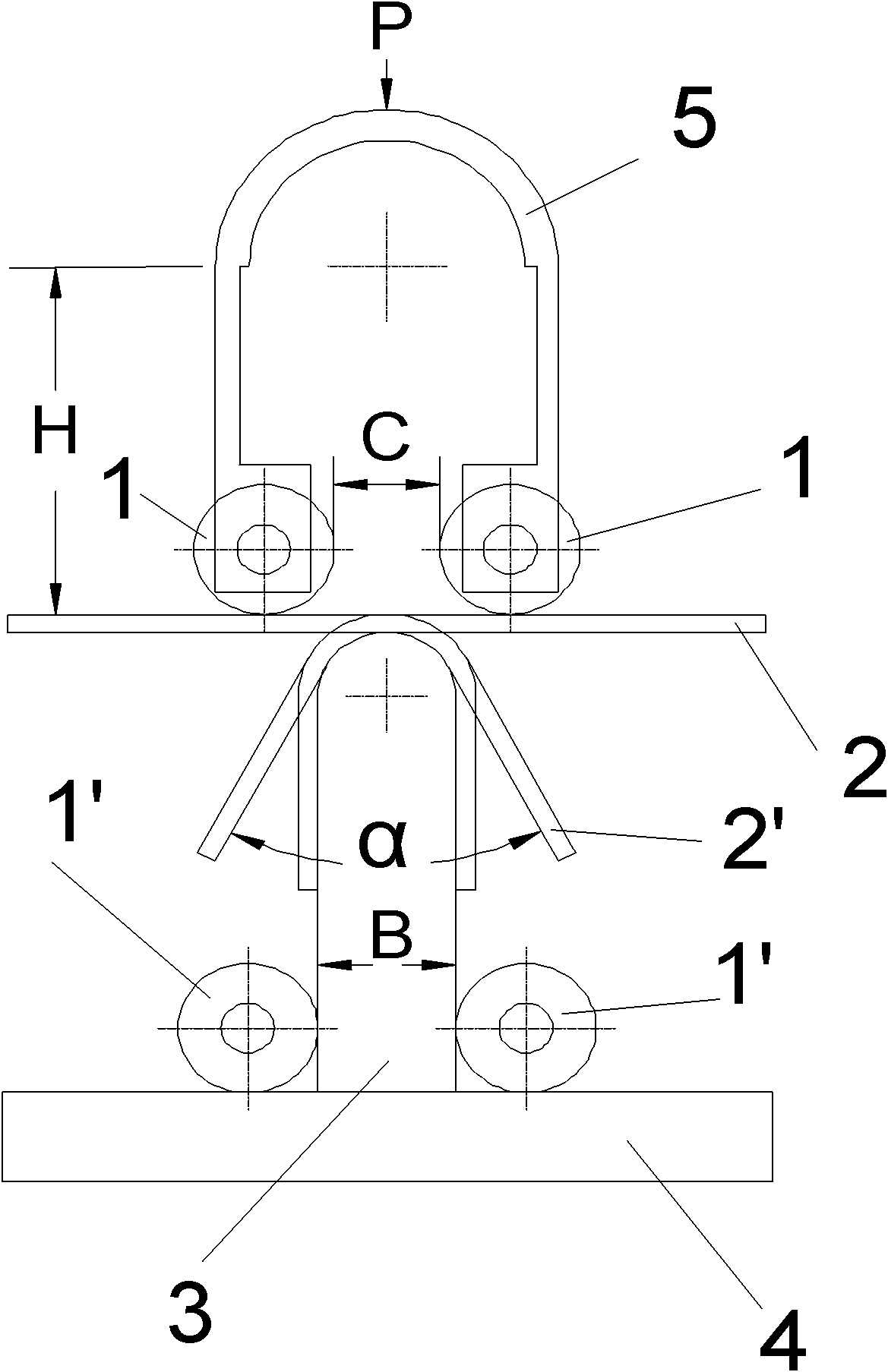

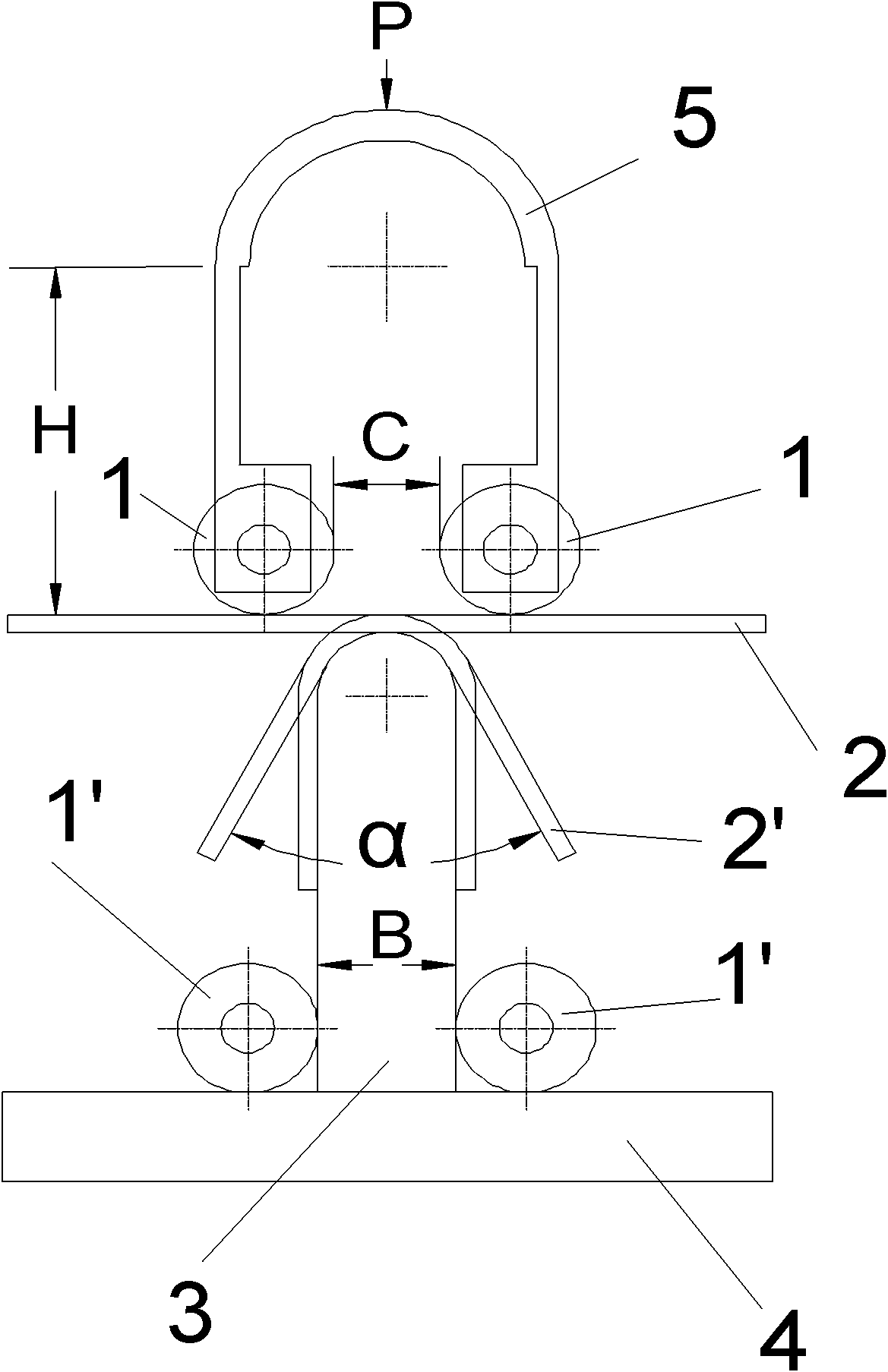

[0015] Such as figure 1 As shown, in the figure 1 is two guide wheels, which are installed at the lower end of the elastic sheet 5, 2 is a U-shaped thin strip to be tested, which is located at the lower end of the two guide wheels, there is an opening (C) between the two guide wheels, and 3 is a punch Head, located at the lower end of the guide wheel 1, 4 is a support plate, located at the lower end of the punch; the width of the opening (C) is smaller than the thickness B of the punch (3), so as to clamp the measured thin strip forming part 2' during stamping, The upper end of the punch is semicircular and has a smooth surface. The height H should be such that the guide wheel rushes to the position of guide wheel 1' in the figure, so that the guide wheel is away from the lower foot of part 2'.

[0016] T10 steel is selected as the elastic sheet 5 with a thickness of 2mm and a width of 15mm. H is 80mm, the tested strip 2 is 0.2×1.6 tin-coated copper strip, the substrate coppe...

Embodiment 2

[0018] The situation is basically the same as in Example 1, except that the 0.2mm thick tin-coated copper strips that have been generally annealed and fully annealed are used as the tested strips, and the obtained α values are 15° and 10° respectively.

Embodiment 3

[0020] The situation is basically the same as in Example 1, except that the 0.5mm thick tin-coated copper strips that have been generally annealed and fully annealed are used as the tested strips, and the obtained α values are 15° and 10° respectively.

[0021] The application of the present invention on the tin-coated copper strip on the photovoltaic cell board is of great significance! The supplier of tin-coated copper strip can mark the springback angle α value, and the application company can also use this device to test its softness and hardness. It is no longer necessary to scrape off the coating and then use a hardness tester to identify soft and hard. That is to say, the larger the rebound angle α value of the tin-coated copper strip, the harder it is, and the higher the debris rate in the process of welding silicon cells, and vice versa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com