Displacement Measuring Device

A technology of displacement measurement and measuring rod, applied in the direction of micrometer, etc., can solve the problems of deviation of measured value, difficult rotation of measuring rod, increase of friction force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

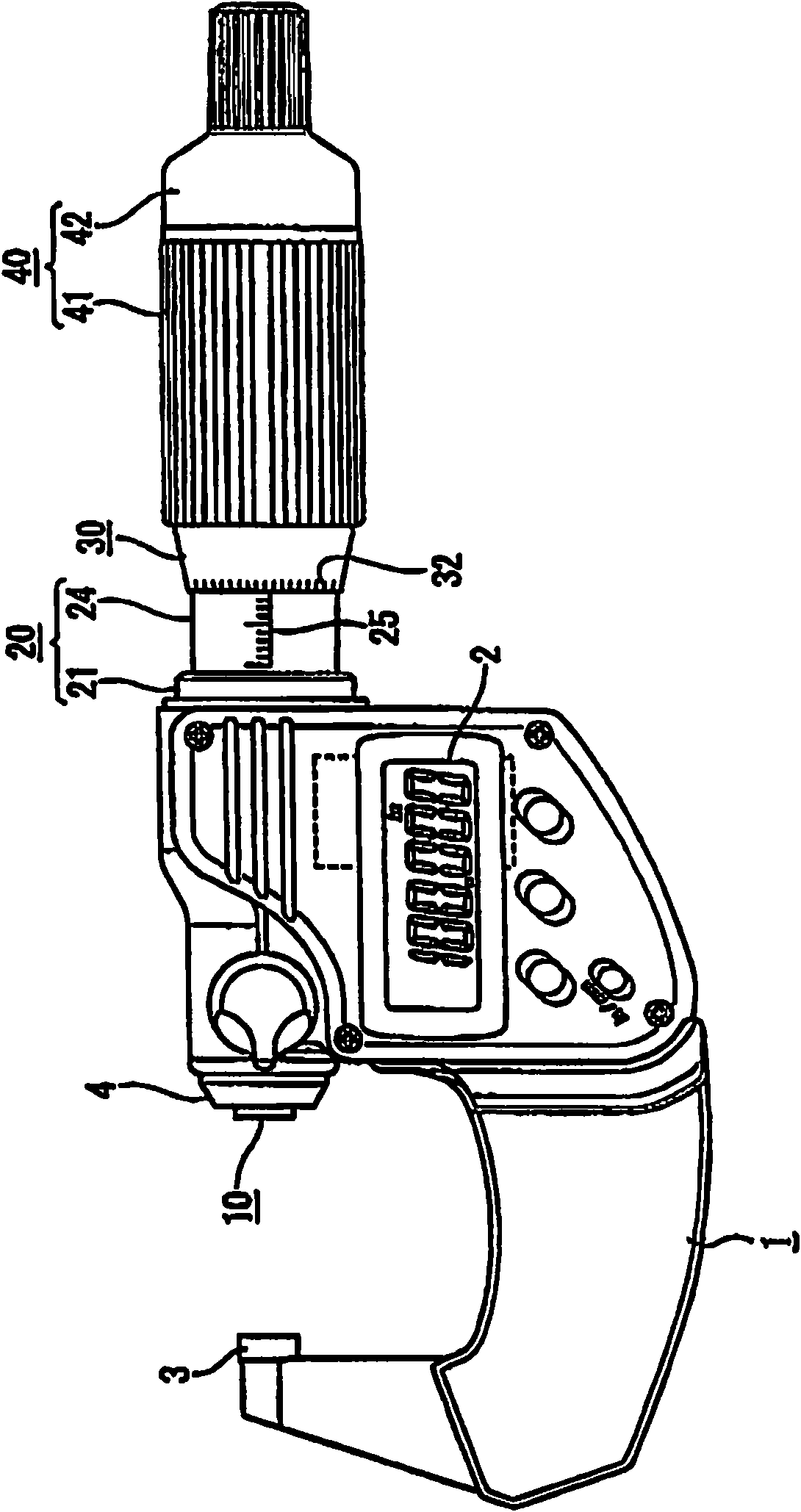

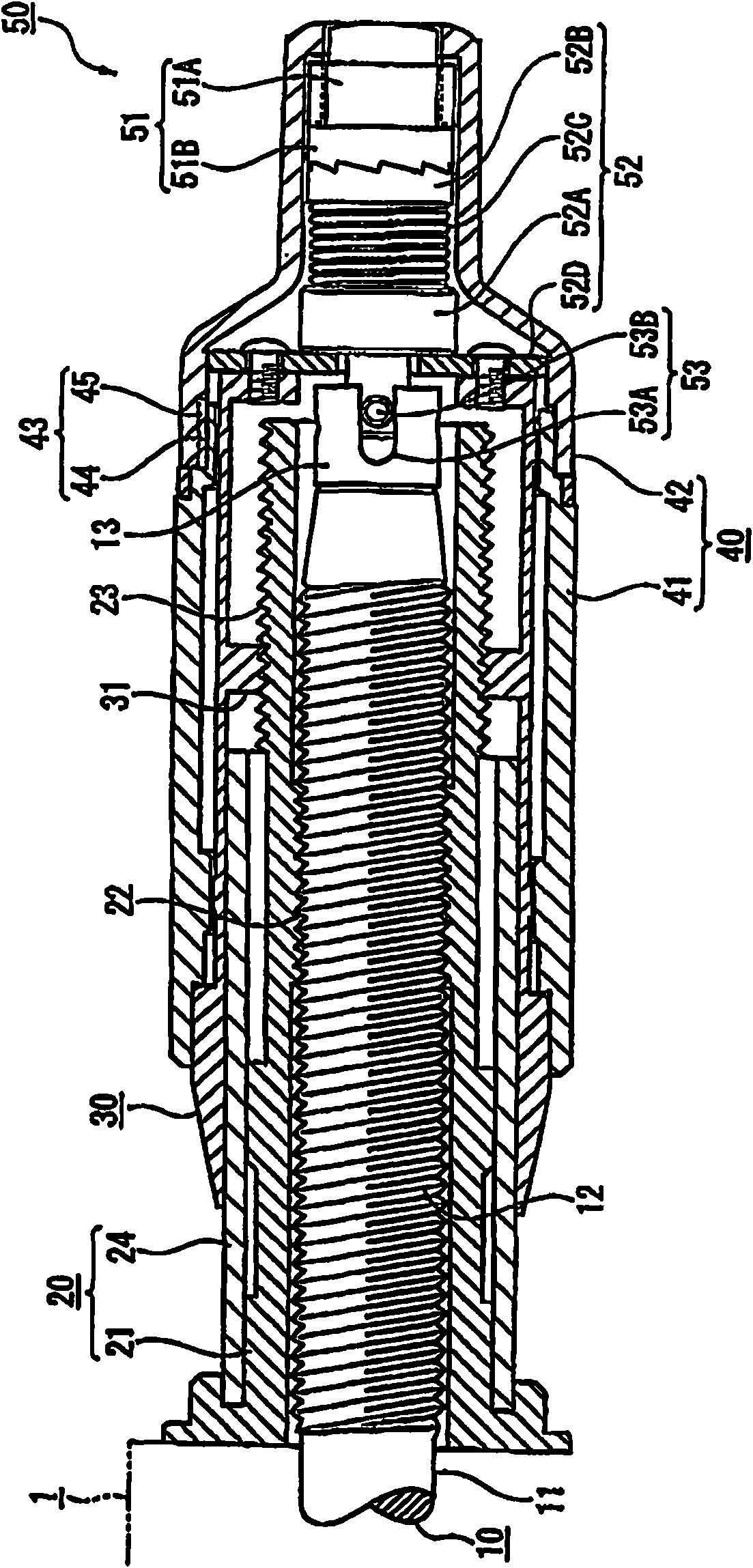

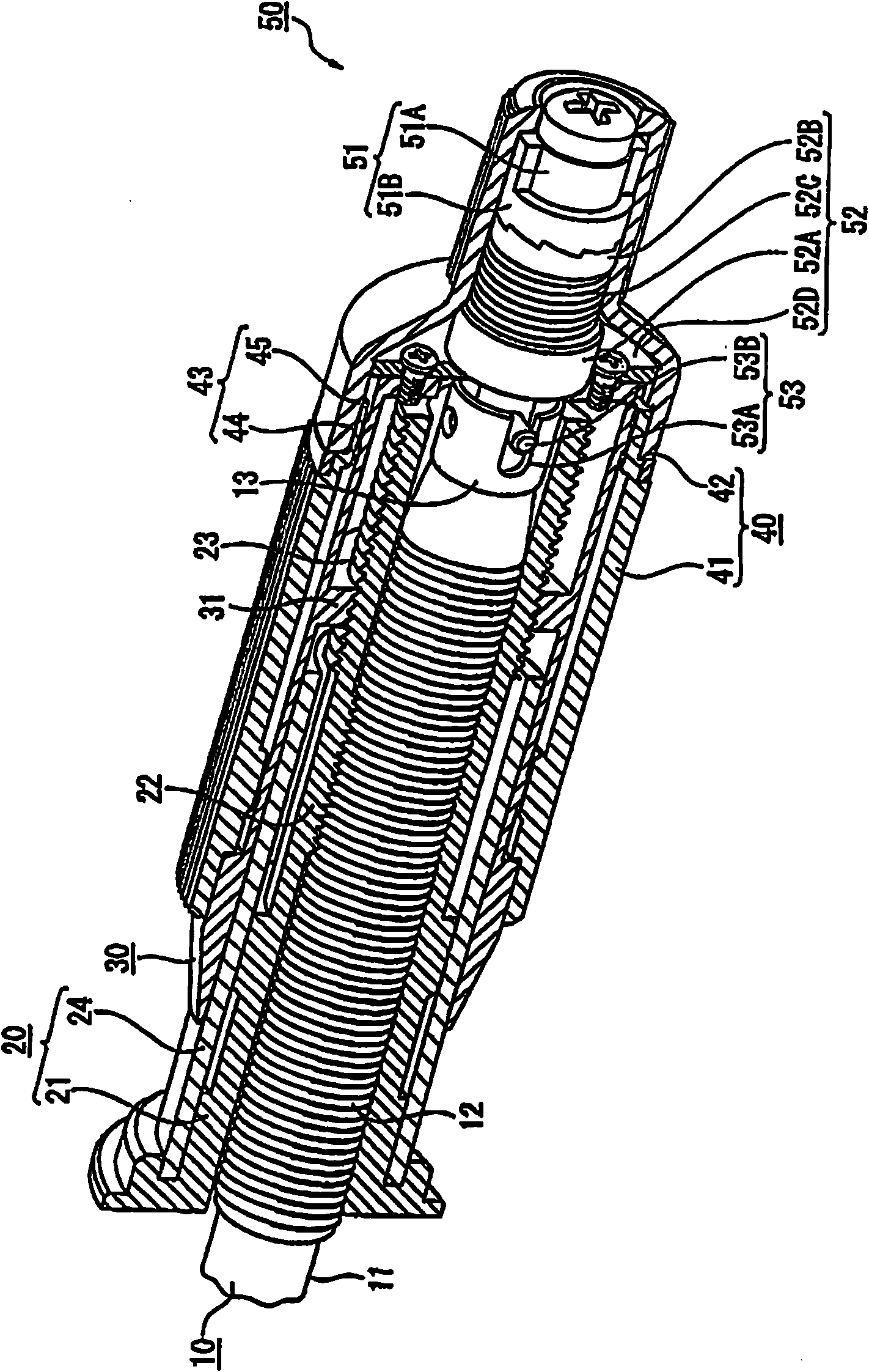

[0020] Hereinafter, embodiments of the present invention will be described based on the drawings. In this embodiment, an example of a digital micrometer will be described as a displacement measuring device.

[0021] Structure of digital micrometer

[0022] Such as figure 1 As shown, the digital micrometer has a substantially U-shaped main body 1, a measuring rod 10 slidably installed on the main body 1, and an encoder (not shown) for detecting the displacement of the measuring rod 10 inside the main body 1. . A digital display 2 for displaying the displacement (measured value) of the measuring rod 10 detected by the encoder.

[0023] An anvil 3 is fixed at one end of the main body 1 , and a bearing cylinder 4 for supporting the measuring rod 10 in a manner to support the measuring rod 10 to slide freely is provided at the other end.

[0024] The inner end side of the measuring rod 10 passes through the bearing cylinder 4 and is supported by the bearing cylinder 4 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com