Windproof construction device for high bridge pier

A technology for construction devices and high bridge piers, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of prolonging the construction period, increasing the pump power, generating grooves and seams on the surface of the pier body, and staggering the platform, so as to ensure the strength and quality. The effect of increasing bending stiffness and wind resistance is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

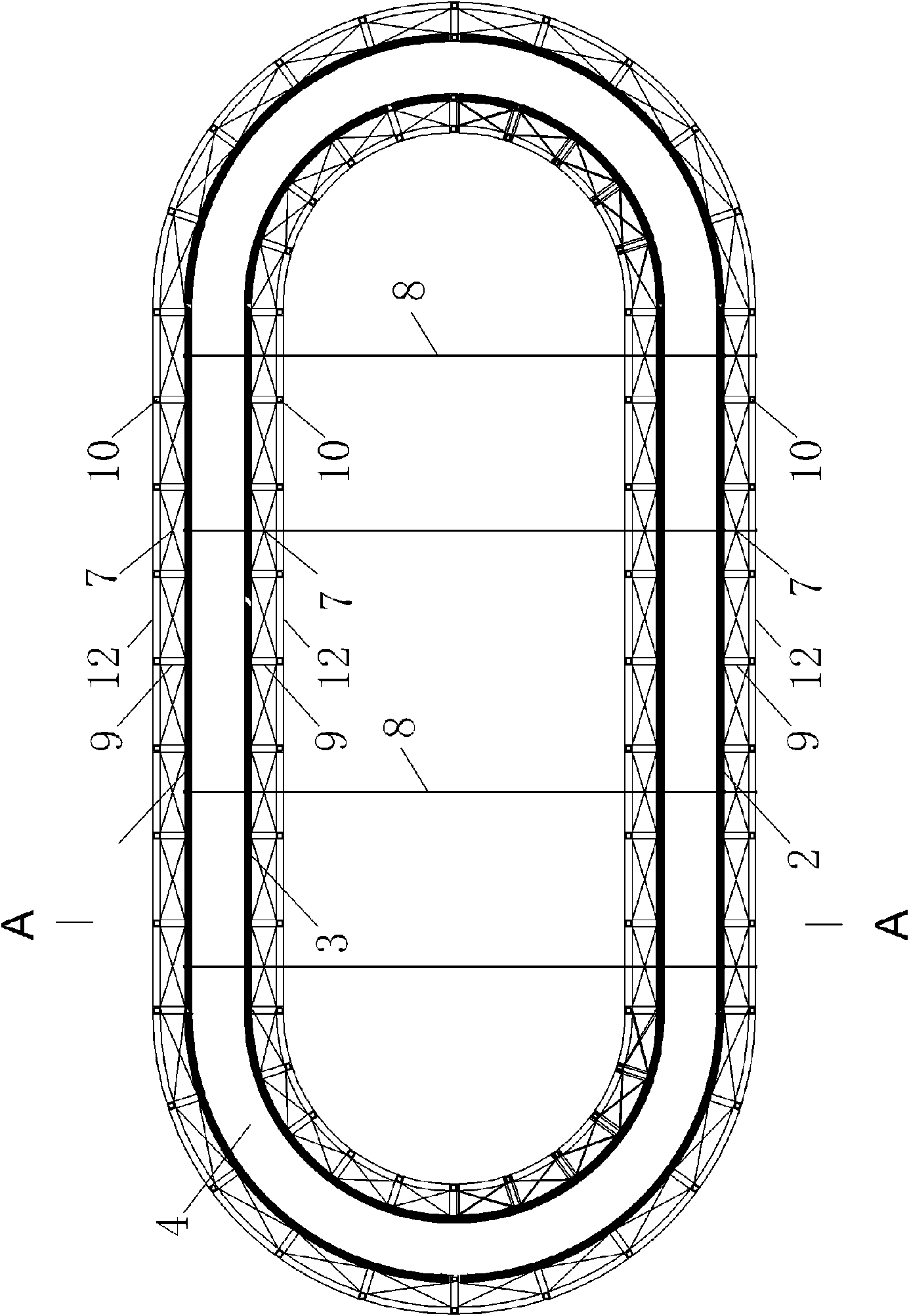

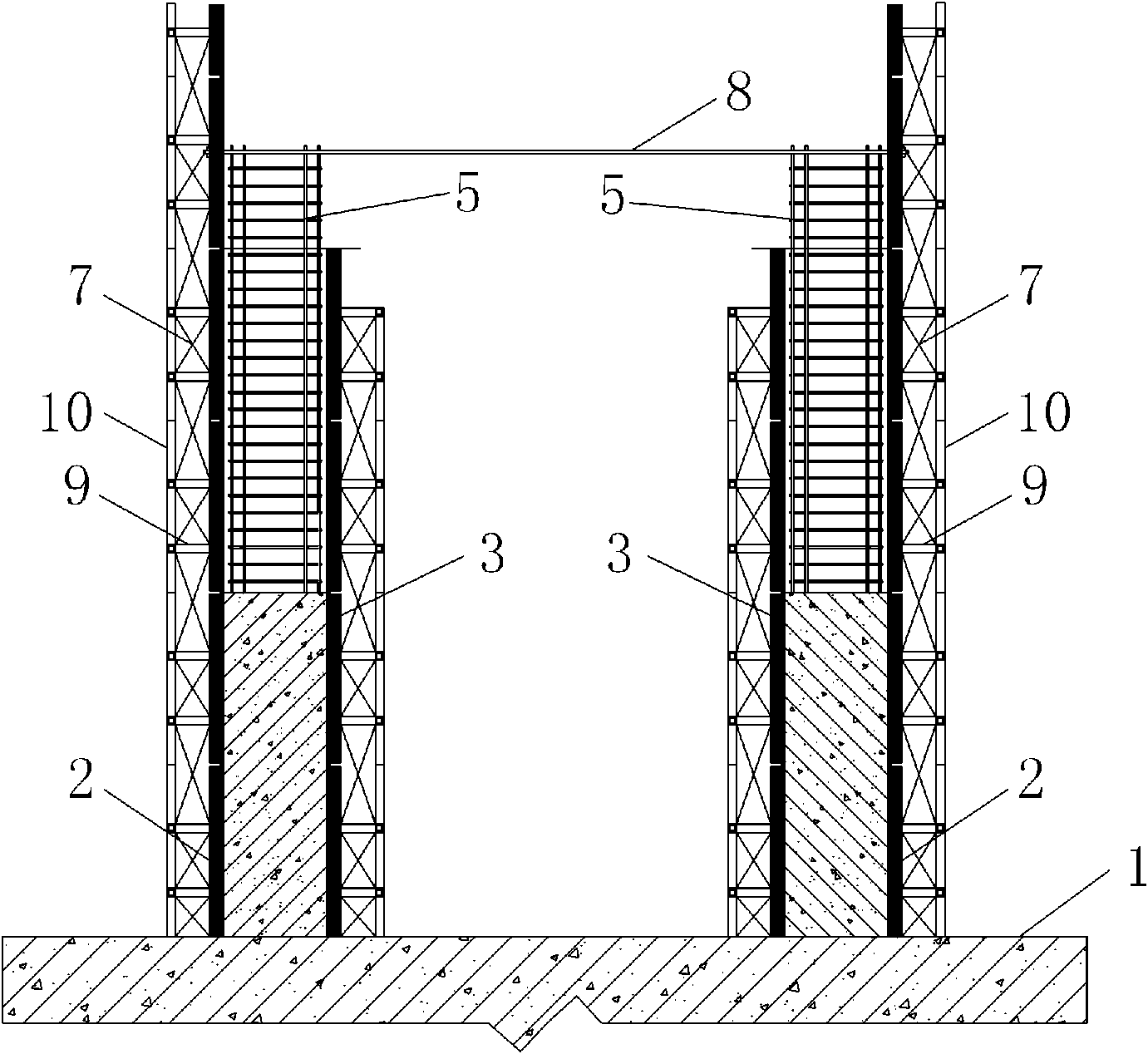

[0022] figure 1 , 2 As shown, a specific embodiment of the present invention is: a windproof construction device for high bridge piers, including an inner formwork 3 and an outer formwork 2 arranged on the inside and outside of the steel cage 5 on the pier cap 1, and is characterized in that : the outer formwork 2 is 31.3-1.8m higher than the inner formwork; the inner side of the inner formwork 3 and the outer side of the outer formwork 2 are fixedly connected.

[0023] figure 2 It is shown that the outer formwork 2 is composed of a lower part of the same height as the inner formwork 3 and an upper part higher than the inner formwork 3, and the upper and lower parts are fixed by bolts.

[0024] figure 1 , 2 It is shown that the top of the reinforcement cage 5 is connected with a detachable tie rod 8 in the direction perpendicular to the long side direction of the bridge pier, and the ends of the tie rod 8 are fixed on the outer formwork 3 .

[0025] The specific composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com