Coal powder delivery pipeline for GSP (Gaskombinat Schwarze Pumpe) gasifier and feeding method

A technology of pulverized coal transportation and feeding method, which is applied in the field of coal chemical industry, and can solve problems such as burnt out water wall, partial burning of gasifier, uneven dispersion of pulverized coal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

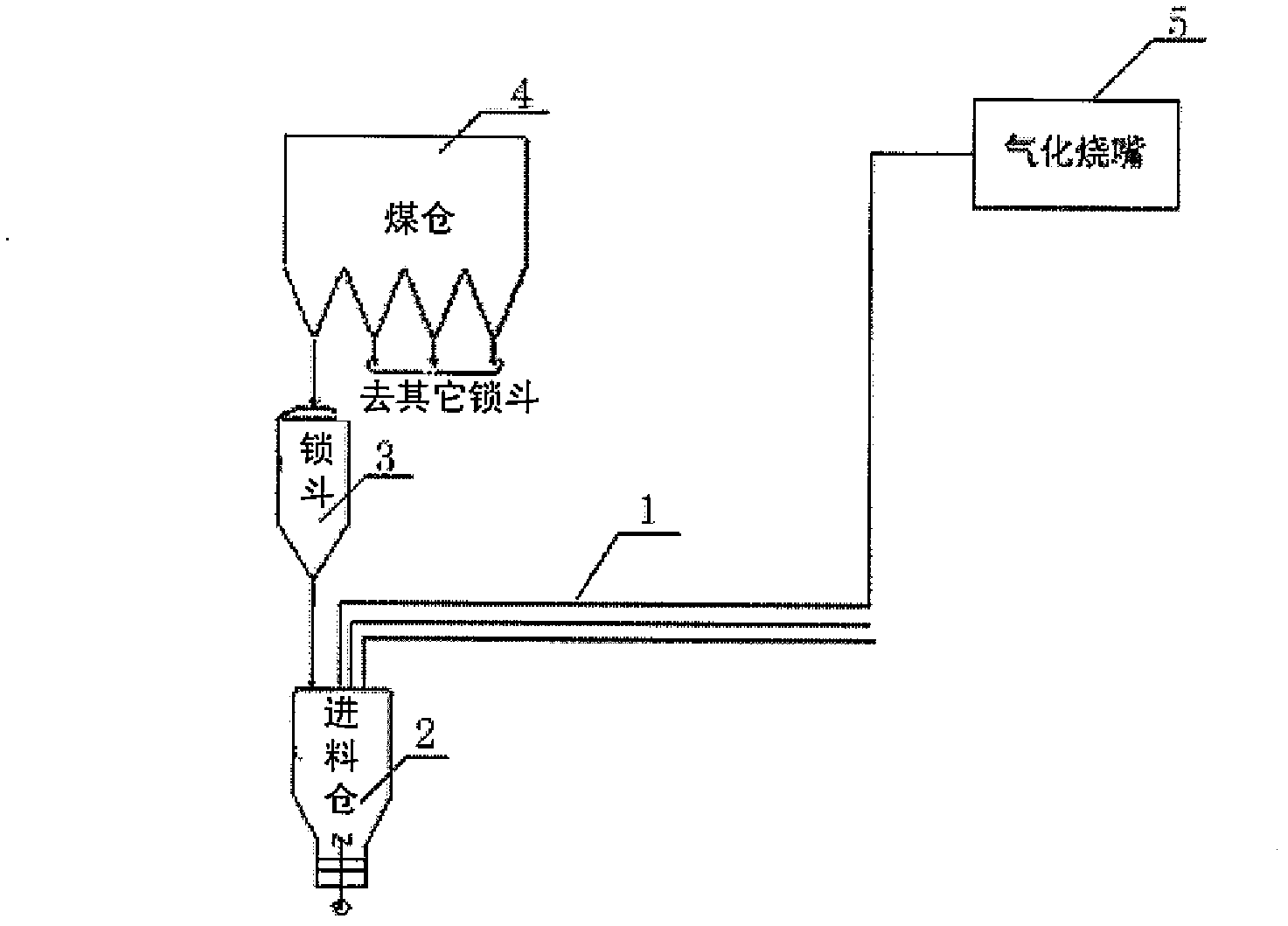

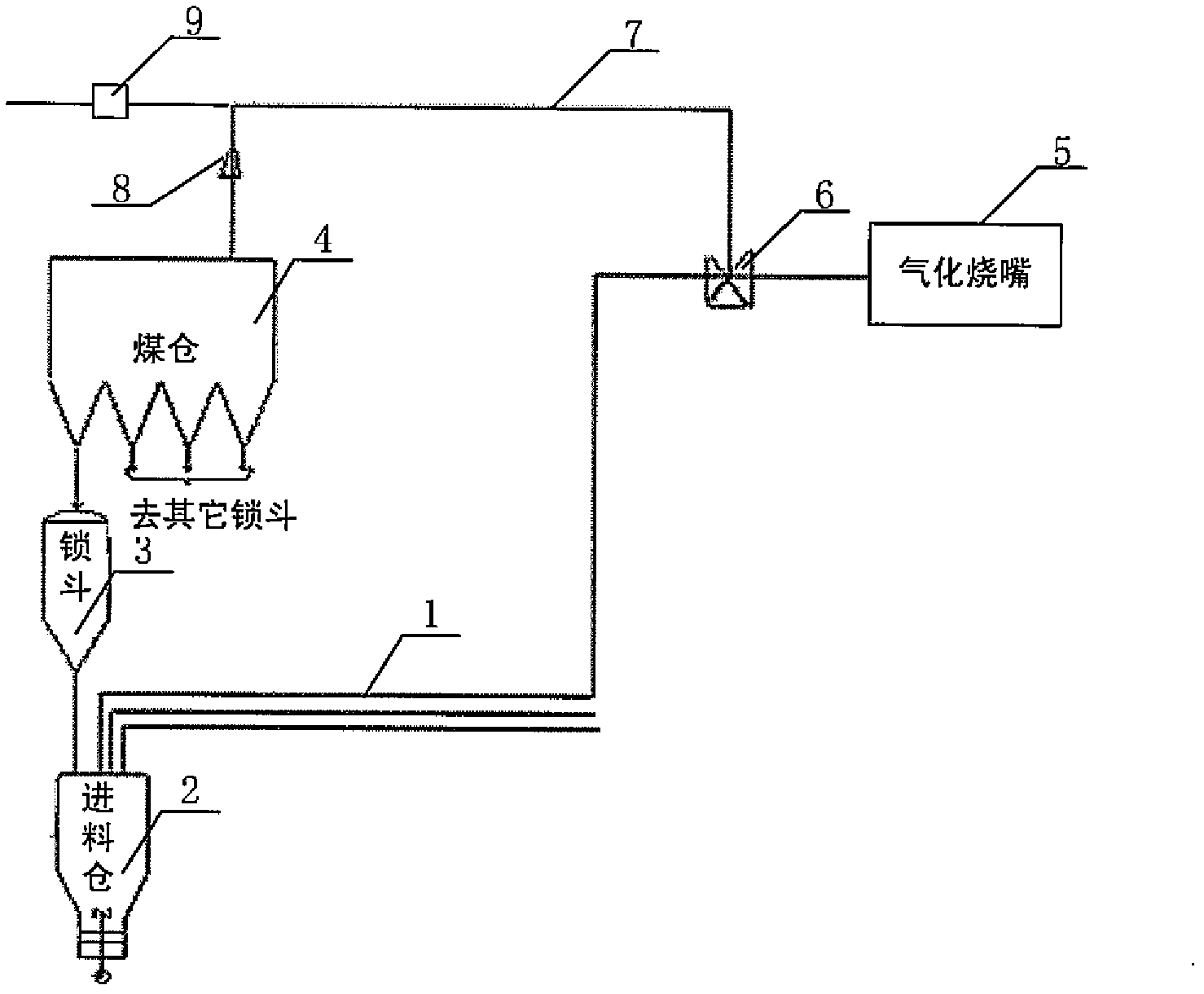

[0028] The invention provides a pulverized coal conveying pipeline and a feeding method for a GSP gasifier, which can adjust the conveying condition of the pulverized coal in the pulverized coal conveying pipeline until the pulverized coal conveying condition in the pulverized coal conveying pipeline Stability, before feeding to the GSP gasifier.

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] figure 2 It is a schematic structural view of the pulverized coal delivery pipeline of the GSP gasifier in the present invention, the pulverized coal gasifier of the GSP includes three pulverized coal delivery pipelines 1, and the three pulverized coal delivery pipelines 1 have the same structure, and are designed for the three pulverized coal delivery pipelines The settings are the same, and for the sake of simplicity, a pulverized coal pipeline is used as an example to illustrate ( figure 2 The pulverized coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com