A kind of preparation method for the lead carbonate combustion catalyst of solid propellant

A technology of burning catalysts and solid propellants, applied in the direction of lead carbonate, offensive equipment, compressed gas generation, etc., can solve the problems of wide particle size distribution of finished powder, troubles in industrialization, high supersaturation, etc., and achieve good crystallinity, Ease of large-scale production, good dispersion of powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

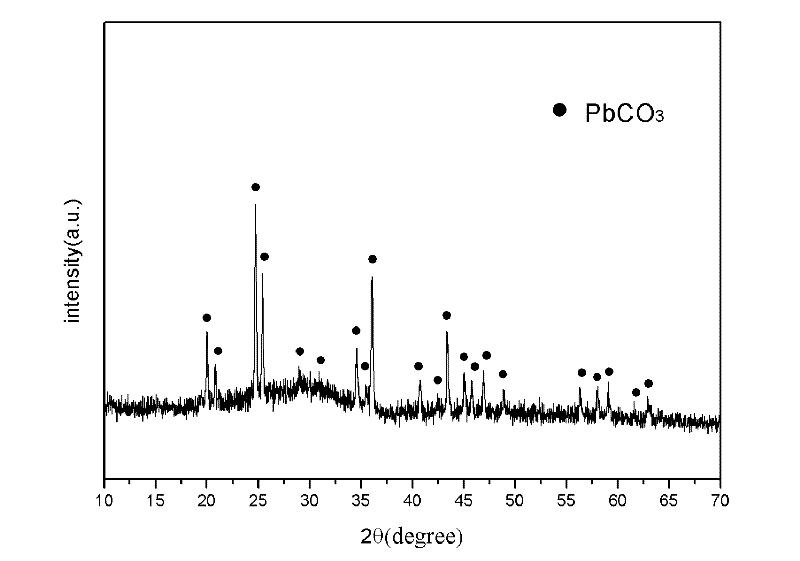

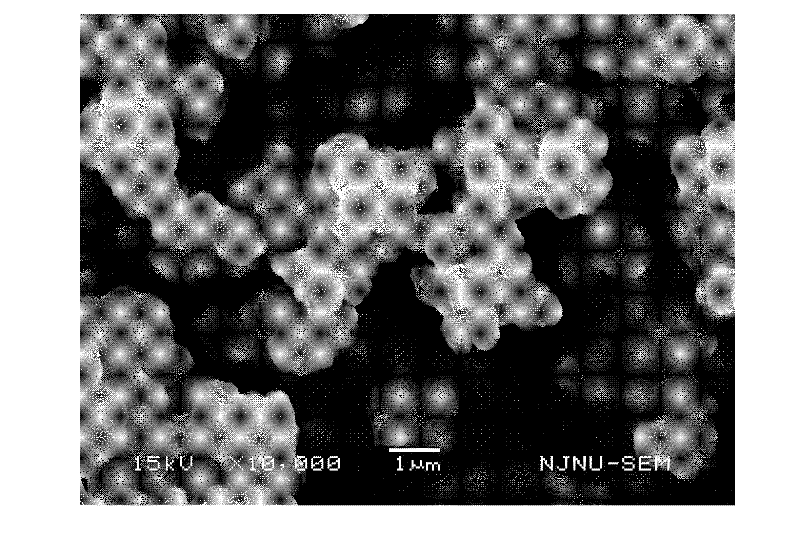

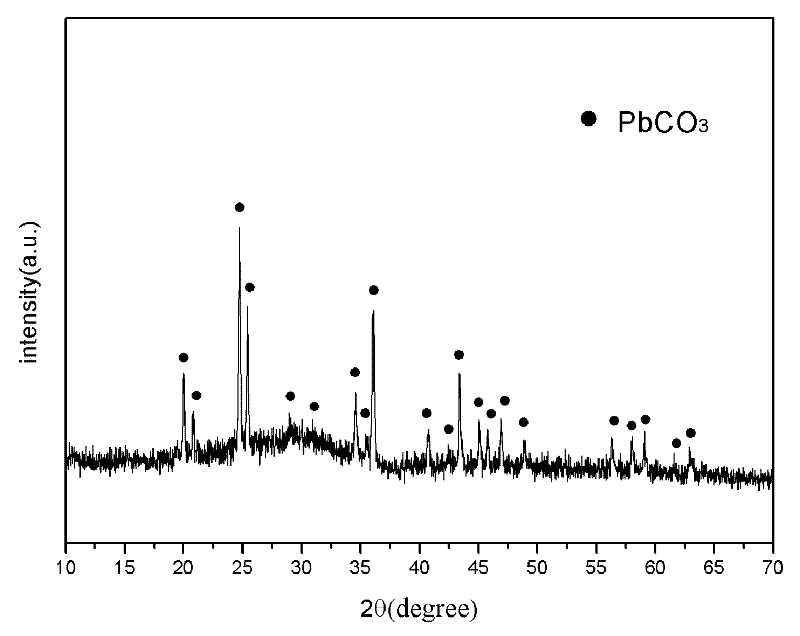

Image

Examples

example 1

[0026] This embodiment includes the following steps:

[0027] Step 1: Weigh a certain amount of lead acetate, zirconium nitrate and tetrabutyl titanate and dissolve them in ethylene glycol to form Pb 2+ 、Zr 4+ 、Ti 4+ Precursor monomers with respective concentrations of 1.0mol / L, 0.5mol / L, and 1.0mol / L;

[0028] Step 2: Then in Ti 4+ Add a certain amount of acetylacetone to the precursor monomer solution, so that the concentration of acetylacetone is 2.0mol / L;

[0029] Step 3: According to the PbZr to be synthesized 0.52 Ti 0.48 o 3 The stoichiometric ratio of the sol takes a certain amount of the three precursor monomer solutions obtained in step 1 and step 2 and mixes them evenly, so that the concentration of the obtained PZT precursor is 0.3mol / L;

[0030] Step 4: Add a certain amount of acetic acid to the PZT precursor obtained in Step 3 to adjust its pH to 3, and stir the solution for 3 hours to form a PZT sol;

[0031] Step 5: Weigh 50ml of sol and add it to the ...

example 2

[0035] This embodiment includes the following steps:

[0036] Step 1: Weigh a certain amount of lead oxide, zirconium oxychloride and titanium oxide and dissolve them in ethylene glycol methyl ether to form Pb 2+ 、Zr 4+ 、Ti 4+ Precursor monomers with respective concentrations of 1.0mol / L, 0.5mol / L, and 1.0mol / L;

[0037] Step 2: Then in Ti 4+ Add a certain amount of acetylacetone to the precursor monomer solution, so that the concentration of acetylacetone is 2.5mol / L;

[0038]Step 3: According to the PbZr to be synthesized 0.52 Ti 0.48 o 3 The stoichiometric ratio of the sol takes a certain amount of the three precursor monomer solutions obtained in step 1 and step 2 and mixes them evenly so that the concentration of the PZT precursor is 0.3mol / L;

[0039] Step 4: Add a certain amount of acetic acid to the PZT precursor obtained in Step 3 to adjust its pH to 3, and stir the solution for 2 hours to form a PZT sol;

[0040] Step 5: Take 50ml of the sol obtained in step...

Embodiment 3

[0044] This embodiment includes the following steps:

[0045] Step 1: Take a certain amount of lead nitrate, zirconium chloride and titanium chloride respectively and dissolve them in ethylene glycol ether to form Pb 2+ 、Zr 4+ 、Ti 4+ Precursor monomers whose respective concentrations are 1.2mol / L, 0.6mol / L, and 1.0mol / L;

[0046] Step 2: Then in Ti 4+ Add a certain amount of acetylacetone to the precursor monomer solution, so that the concentration of acetylacetone is 2.0mol / L;

[0047] Step 3: According to the PbZr to be synthesized 0.52 Ti 0.48 o 3 The stoichiometric ratio of the sol takes a certain amount of the three precursor monomer solutions obtained in step 1 and step 2 and mixes them evenly so that the concentration of the PZT precursor is 0.5mol / L;

[0048] Step 4: Add a certain amount of acetic acid to the PZT precursor obtained in Step 3 to adjust the pH of the precursor to 4, and stir the solution for 1 hour to form a PZT sol.

[0049] Step 5: Weigh 50ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com