Fully automatic solar barrel processing machine

A solar energy, fully automatic technology, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of difficulty in ensuring product quality, low production efficiency, high labor intensity, etc., and achieve simple operation, low production cost, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

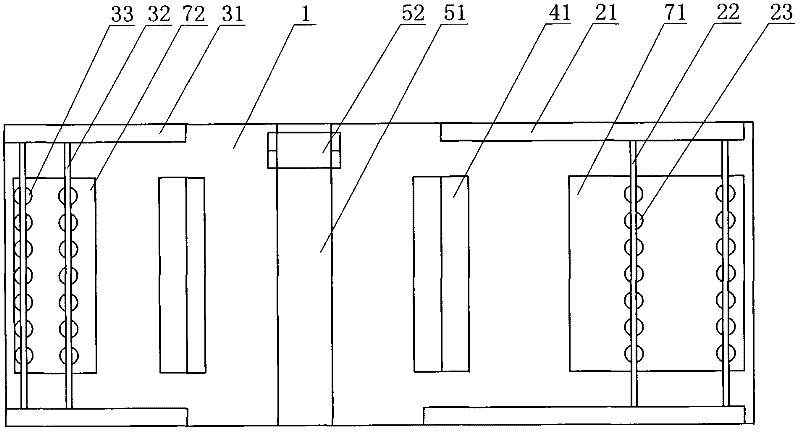

[0050] Such as figure 1 with figure 2 As shown, the fully automatic solar outer barrel processing machine is used to bend the sheet materials into a cylindrical shape, and includes a frame 1, and one end of the frame 1 is equipped with a main board material feeding device. The other end is equipped with an auxiliary sheet material feeding device, and a sheet material bending device is installed on the frame 1 at the stroke end of the main sheet material feeding device and the auxiliary sheet material feeding device, and the sheet material bending device The frame 1 above is equipped with a sheet material hemming device and a sheet material butt joint pressing device, and the frame 1 is also provided with an automatic barrel discharge device. The sheet material in this embodiment is divided into main sheet material 71 and auxiliary sheet material 72 .

[0051] Described main material feeding device comprises the main material mobile slide rail 21 that is installed on the des...

Embodiment 2

[0070] Such as Figure 23 with Figure 24 As shown, the fully automatic solar outer barrel processing machine is used to bend the sheet materials into a cylindrical shape, and includes a frame 1, and one end of the frame 1 is equipped with a main board material feeding device. The other end is equipped with an auxiliary sheet material feeding device, and a sheet material bending device is installed on the frame 1 at the stroke end of the main sheet material feeding device and the auxiliary sheet material feeding device, and the sheet material bending device The frame 1 above is equipped with a sheet material hemming device and a sheet material butt joint pressing device, and the frame 1 is also provided with an automatic barrel discharge device. The sheet material in this embodiment is divided into main sheet material 71 and auxiliary sheet material 72 .

[0071]Described main material feeding device comprises the main material mobile slide rail 21 that is installed on the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com