Thick Film Spin Coating Method for Semiconductor Packaging

A technology of semiconductor and adhesive film, which is applied in the manufacture of semiconductor/solid-state devices, devices for coating liquid on the surface, and coatings, etc. It can solve the problems of slow consumption of edge solvents, long fusion time, and fast consumption of intermediate solvents, etc., to achieve saving The cost of equipment transformation and the effect of simple process debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

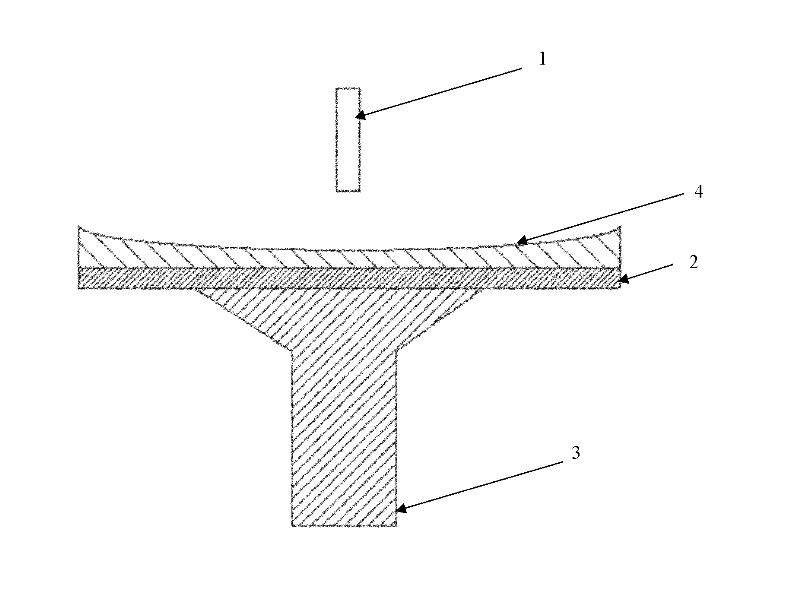

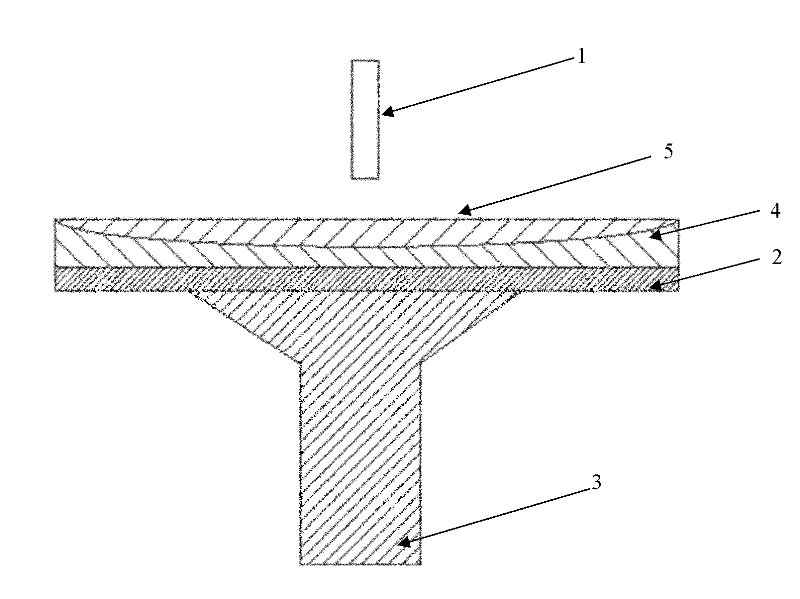

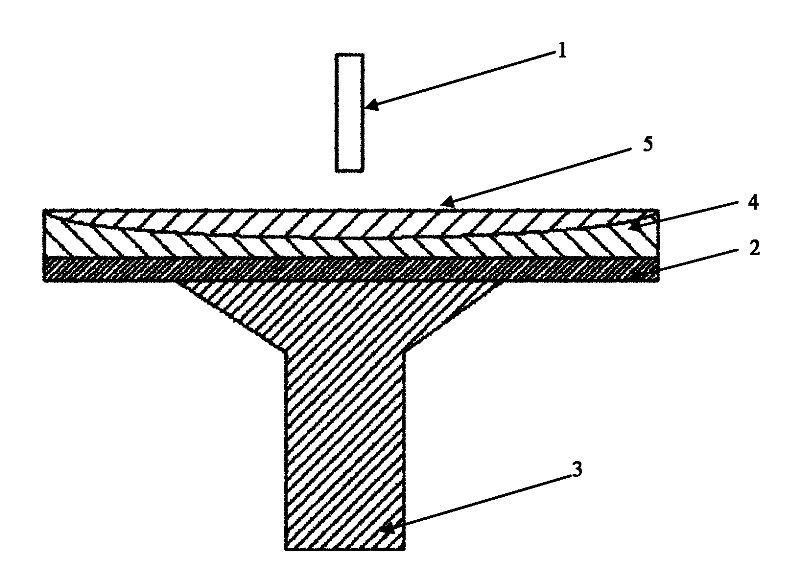

[0019] In this embodiment, when applying glue for the first time, the viscosity of the positive photoresist is 300 centipoise, and the rotation speed of the vacuum chuck is 1200 rpm; when applying glue for the second time, the viscosity of the positive photoresist is 300 centipoise , the rotation speed of the vacuum chuck is 1200rpm; the distance between the outlet of the dripping pipeline 1 and the wafer 2 is 15mm, and the diameter of the wafer 2 is 8 inches.

Embodiment 2

[0021] In this embodiment, when applying glue for the first time, the viscosity of the negative photoresist is 4000 centipoise, and the rotation speed of the vacuum chuck is 1500 rpm; when applying glue for the second time, the viscosity of the negative photoresist is 4000 centipoise , the rotation speed of the vacuum chuck is 1600rpm; the distance between the outlet of the dripping pipeline 1 and the wafer 2 is 10mm, and the diameter of the wafer 2 is 12 inches.

Embodiment 3

[0023] In this embodiment, when applying glue for the first time, the viscosity of the negative photoresist is 1500 centipoise, and the rotation speed of the vacuum chuck is 3000 rpm; when applying glue for the second time, the viscosity of the negative photoresist is 1500 centipoise , the rotation speed of the vacuum chuck is 2800rpm; the distance between the outlet of the dripping pipeline 1 and the wafer 2 is 20mm, and the diameter of the wafer 2 is 8 inches.

[0024] The results of the examples show that the present invention achieves that the center of the glue-coated film is slightly thinner and the edge is slightly thicker for the first time through the control of the glue-spraying speed and the glue-spinning speed through the central glue-dropping and rotating glue-coating. The invention realizes that the center of the second glue coating film is slightly thicker and the edge is slightly thinner through the control of the glue spreading speed and the glue throwing speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com