Low-density ceramsite filter material for biological aerated filter, and preparation method thereof

A technology of biological aerated filter and ceramsite filter material, which is applied in the field of water treatment, can solve the problems of unfavorable promotion and development of biological aerated filter technology, incomplete backwashing, and high apparent density, and shorten the backwashing time , reduce energy consumption, and avoid the effect of filter material hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

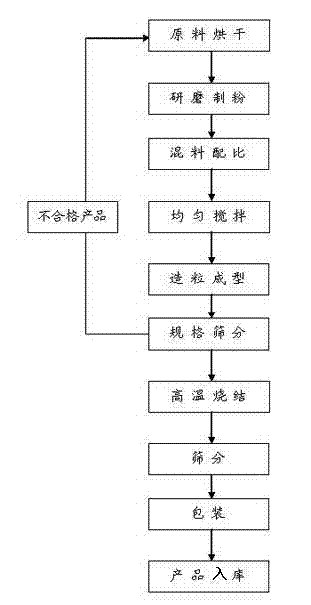

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] like Figure 1 to Figure 2 As shown, a low-density ceramsite filter material for biological aerated filter is mainly made of Guizhou soil, clay, pottery clay, Yichun soil, pore forming agent, binder and charcoal material.

[0027] Calculated by weight percentage, they are: Guizhou soil 20-30%, clay 10-15%, pottery clay 5-12%, Yichun soil 1-5%, pore-forming agent 10-20%, binder 6-15%, Charcoal material 3~15%. The Guizhou soil may be Guizhou kaolin or Guizhou bauxite, and the Yichun soil may be Yichun kaolin or Yichun bauxite.

[0028] The low-density ceramsite filter material is in the shape of spherical particles with a rough surface, and its particle size is 3-6mm. Moreover, the low-density ceramsite filter material has a porous structure, and its porosity is greater than 60%.

[0029] The particle size of the low-density ceramsite f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com