Stator winding connection method for low-voltage high-power multipole multiphase permanent magnet synchronous motor

A permanent magnet synchronous motor and stator winding technology, which is applied to the shape/style/structure of synchronous machine components and winding conductors, and can solve the problems of large total cross-sectional area of phase winding conductors, reduced motor performance, and low battery voltage. , to achieve the effect of reducing the cross-sectional area of the coil conductor, reducing the cross-sectional area of the conductor, and improving the performance of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

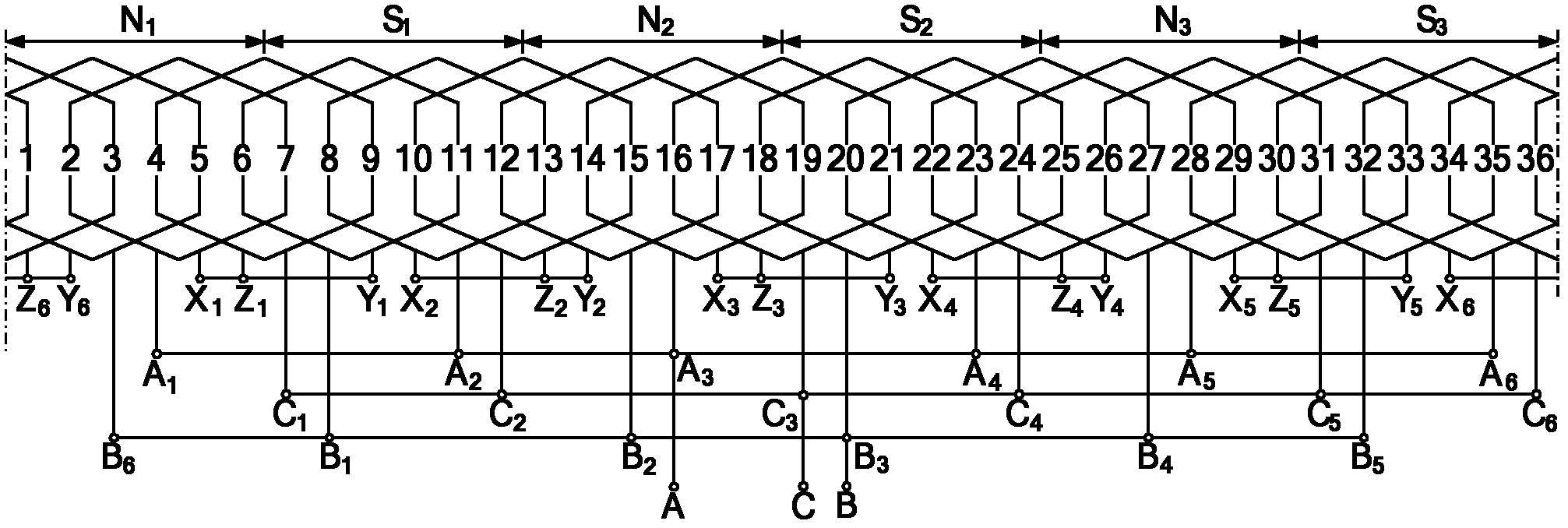

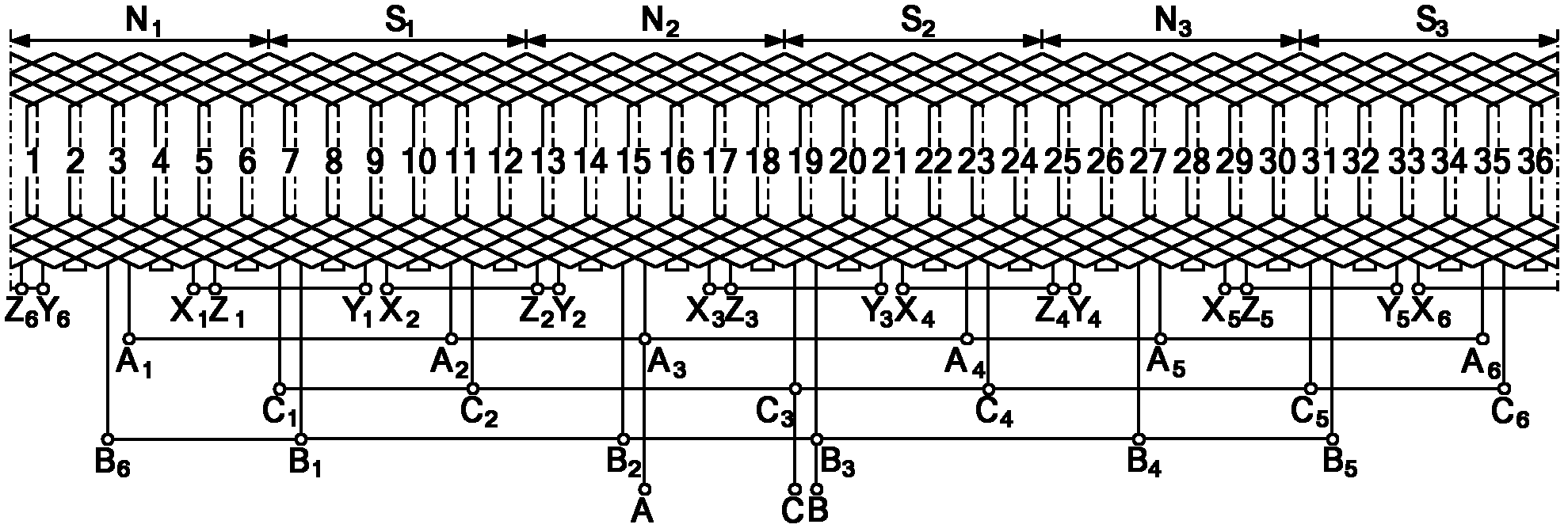

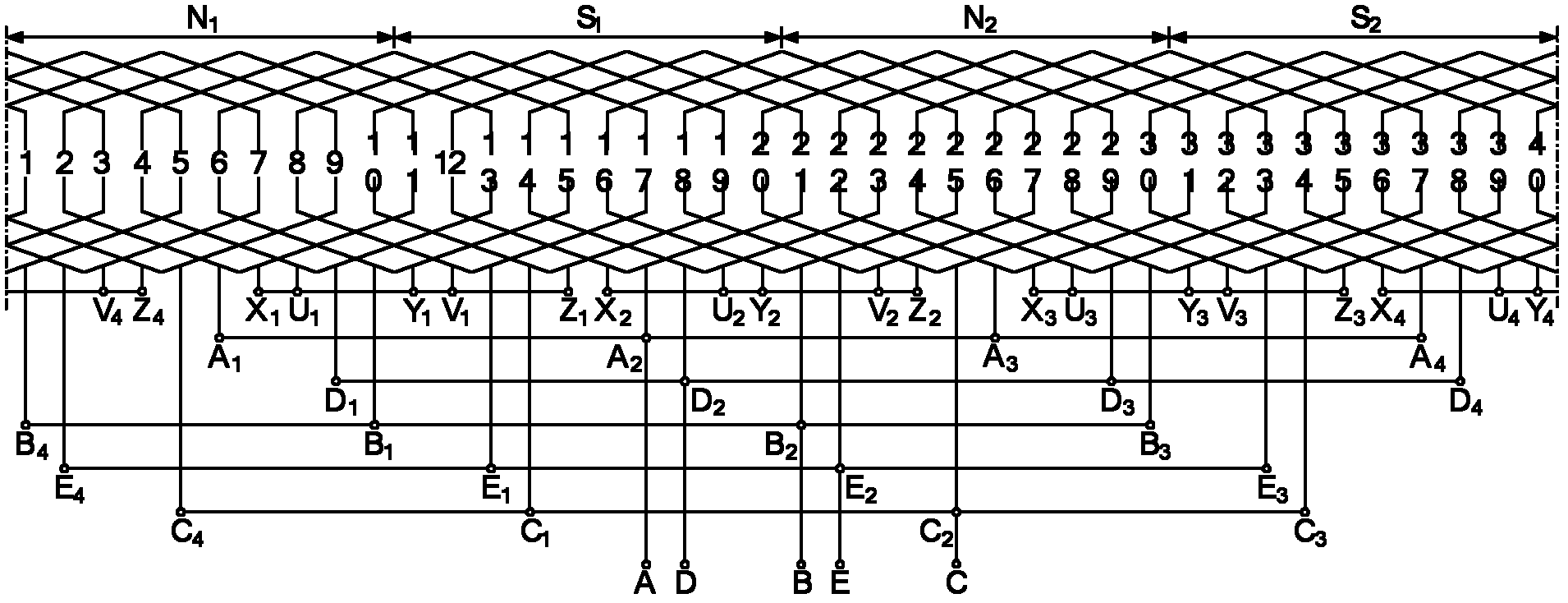

[0018] as attached figure 1 As shown, the number of motor phases m=3, the number of poles 2p=6, the number of stator slots Z=36, the windings are divided into phases according to π / 3 electrical angle, and are connected into 6 star-connected groups in parallel according to the present invention, and each star contact Unconnected AC motor stator single layer winding. In the figure, N 1 , S 1 , N 2 , S 2 , N 3 , S 3 Represents the 6 magnetic poles of the motor rotor, and the numbers 1, 2, L, 35, 36 represent the serial numbers of the 36 slots of the motor. There are 18 coils placed in the stator, and the number of turns of the coils is N. c . A 1 X at the end 1 Coil A 1 x 1The two coil sides of A are respectively embedded in slot 2 and slot 7, and coil A 1 x 1 This coil itself constitutes the first coil group of phase A; the end is A 2 X 2 Coil A 2 x 2 The two coil sides of A are respectively embedded in slot 13 and slot 8, coil A 2 x 2 This coil itself constit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com