CdZnTe (cadmium zinc telluride) thin film solar cell with gradient band gap structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

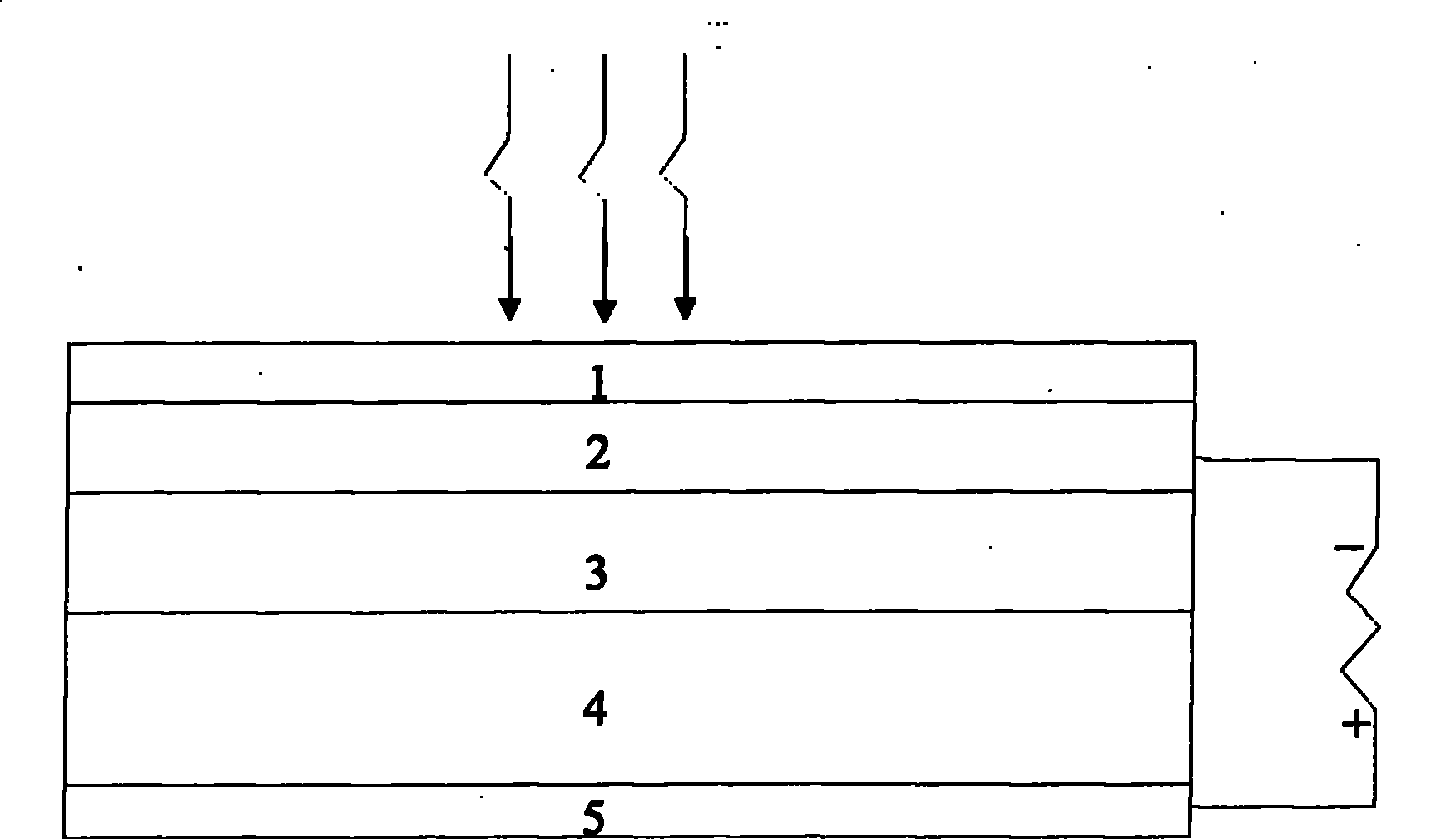

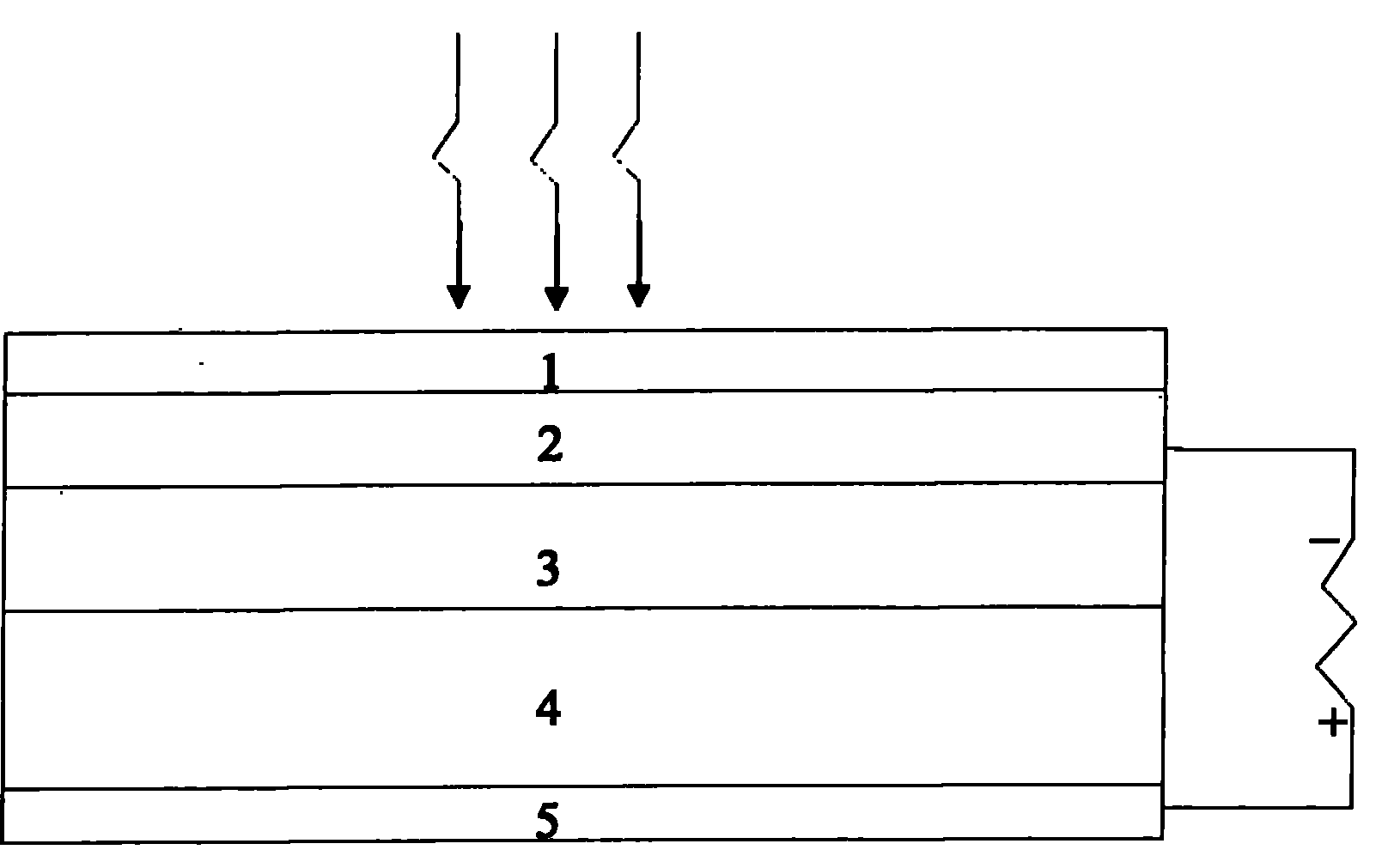

[0015] See figure 1 , Cd with a graded bandgap structure 1-x Zn x Te thin-film solar cells include a glass substrate 1, a transparent conductive oxide front electrode layer 2, an n-type CdS window layer 3, a p-type CdS window layer 3, and a p-type Cd 1-x Zn x Te absorption layer 4, back electrode layer 5.

[0016] A front electrode layer 2 of any transparent conductive oxide among ITO, SnO2:F, and ZnO:Al is thermally evaporated on a glass substrate 1 with a thickness of 200-800 nanometers.

[0017] An n-type CdS window layer 3 with a thickness of 50-100 nanometers is magnetron sputtered on the front electrode layer 2 .

[0018] p-type Cd 1-x Zn x The three regions of the Te absorbing layer 4 are sequentially deposited on the n-type CdS window layer 3 using a double-target co-sputtering method, one target is ZnTe, and the other is CdTe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com