Magazine clip type hole packer

A hole sealer and clip-type technology, which is used in gas discharge, safety devices, mining equipment, etc., can solve problems such as damage to the hole sealer, rupture, and failure to achieve the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

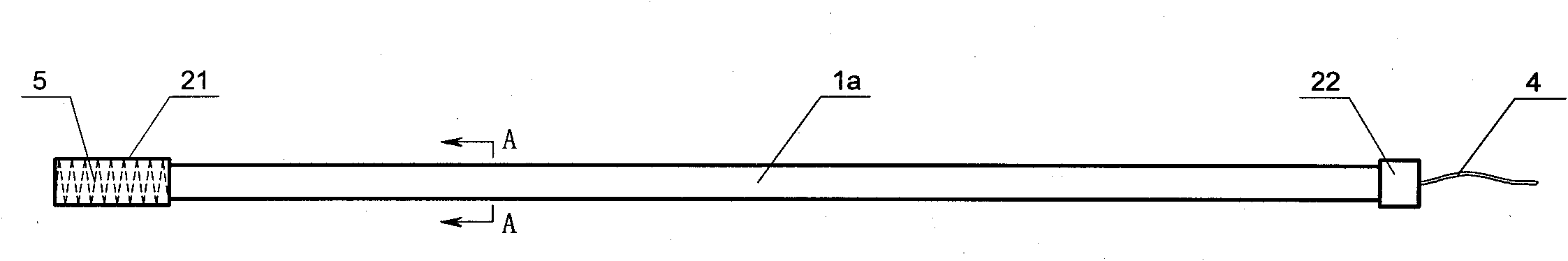

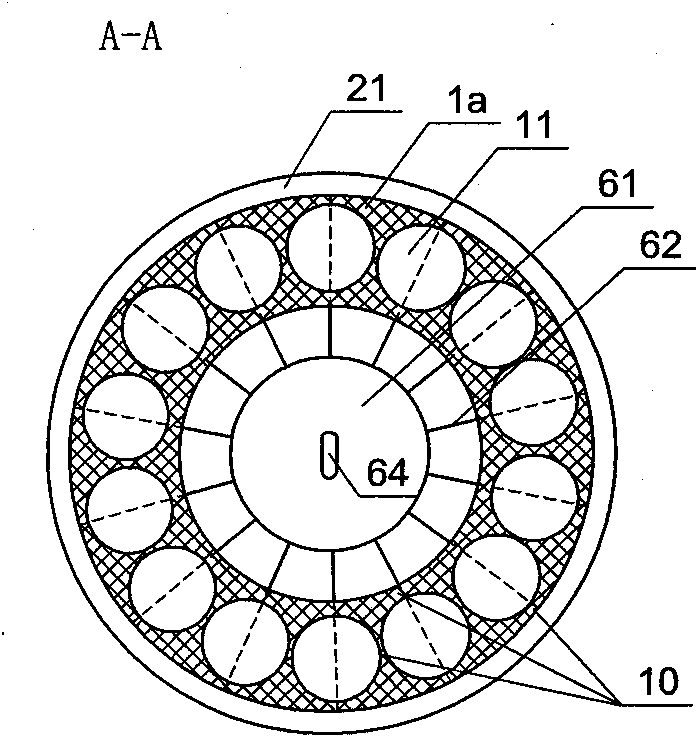

[0027] Embodiment one: see figure 1 and figure 2 , The clip-type hole sealer includes a closed support tube 1a. The annular tube wall of the closed support tube 1a is evenly distributed with drug intestinal cavities 11 , and the adjacent parts of each drug intestinal cavity 11 and the inner and outer surfaces of each drug intestinal cavity and the support tube are film layers 10 . Each medicine intestine cavity 11 is equipped with a medicine intestine, and the adjacent medicine intestines are respectively equipped with an expansion compound A and an expansion compound B, and the expansion compound A and the expansion compound B can rapidly expand and fix after being mixed. In the prior art, there are many materials that expand rapidly after the two solutions are mixed, and will not be described in detail.

[0028] In this embodiment, end caps 21 and 22 are respectively installed on the inner end and the outer end of the closed support tube 1a. A combination cutter is provi...

Embodiment 2

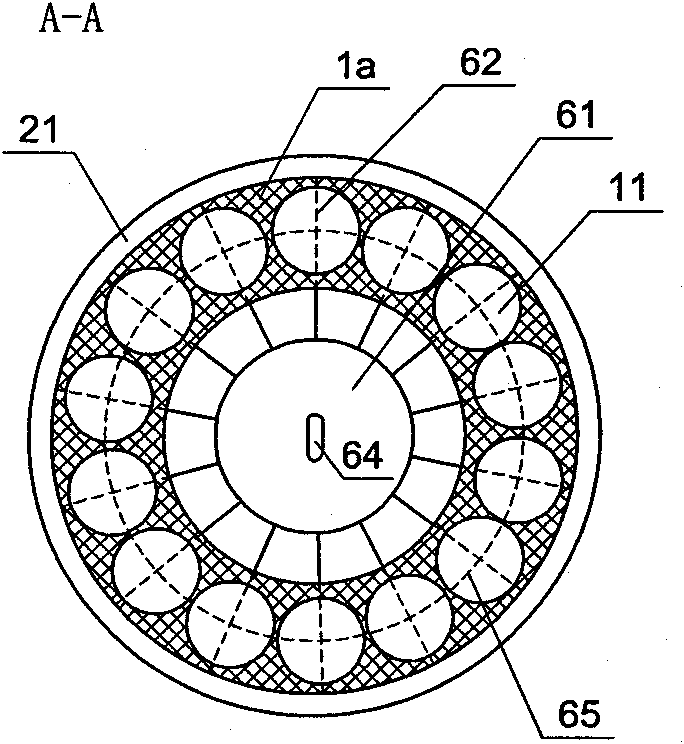

[0030] Embodiment two: see figure 1 and image 3 , the content is basically the same as that of Embodiment 1, and the same parts will not be repeated. The difference is that the combined tool includes an annular blade 65, and radially divergent blades 62 are fixed on the annular blade 65, and each blade 62 is respectively Corresponding to the film layer 10 of the intestinal cavity of the medicine.

Embodiment 3

[0031] Embodiment three: see figure 1 and Figure 4 , the content is basically the same as that of Embodiment 1, and the same parts will not be repeated. The difference is that the combined tool includes an annular blade 65, and radially divergent blades 62 are fixed on the annular blade 65, and each blade 62 is respectively Corresponding to the film layer 10 of the intestinal cavity of the medicine. A stay cord 4 is fixed on the annular blade 65 , and the stay cord 4 protrudes from the closed medicinal intestine cavity 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com