Fermentation production method for citric acid

A production method and technology of citric acid, which is applied in the field of continuous fermentation production of citric acid, can solve the problems of unstable batch fermentation production, large fluctuations in fermentation results, and low utilization rate of fermentation tanks, so as to shorten the fermentation cycle and improve conversion rate, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

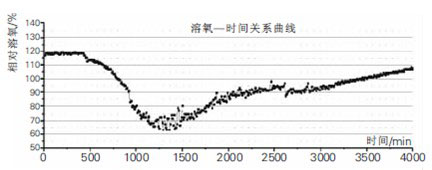

Method used

Image

Examples

Embodiment 1

[0041] at 50m 3 Add seed medium containing 12.5% total sugar (m / m) and Aspergillus niger spores into the seed tank, maintain pH 3-7, temperature 40°C, and cultivate for 12-24 hours to form Aspergillus niger balls for use.

[0042] Add corn fermentation medium containing 12.5% (m / m) of total sugar to 250m 3 In the first-stage fermenter of the tank capacity, when the fermentation medium accounts for 70% of the volume of the fermenter, the ventilation, stirring and cooling systems are activated to maintain the temperature of the material liquid in the fermenter at 35-37°C and inoculate according to 10% of the inoculation amount. Inject Aspergillus niger balls from the seed tank and maintain an air volume of 8.6 m 3 / m 3 h, pH2.9-4.5;

[0043] According to 13.5m 3 The flow rate of / h continuously adds the fermentation medium and the Aspergillus niger balls from the seed tank at a rate of 10% to the primary fermenter, according to 14.85m 3 The flow rate of / h flows out fro...

Embodiment 2

[0049] at 50m 3 Add seed medium containing 13.0% total sugar (m / m) and Aspergillus niger spores into the seed tank, maintain pH 3-7, temperature 38°C, and cultivate for 12-24 hours to form Aspergillus niger balls for use.

[0050] Add corn fermentation medium containing 13.5% (m / m) of total sugar to 250m 3 In the first-stage fermenter of the tank capacity, when the fermentation medium accounts for 80% of the volume of the fermenter, the ventilation, stirring and cooling systems are started to maintain the temperature of the feed liquid in the fermenter at 35-37°C and the inoculation amount of 8% is inoculated. Inject Aspergillus niger balls from the seed tank and maintain an air volume of 9.8 m 3 / m 3 h, pH2.9-4.5;

[0051] Press 13m 3 The flow rate of / h is continuously added to the primary fermenter with fermentation medium and aspergillus niger pellets from the seed tank at a rate of 8%, 14.85m 3 The flow rate of / h flows out from the primary fermentation tank or extra...

Embodiment 3

[0057] at 75m 3 Add seed medium containing 12.5% total sugar (m / m) and Aspergillus niger spores into the seed tank, maintain pH 3-7, temperature 40°C, and cultivate for 12-24 hours to form Aspergillus niger balls for use.

[0058] Add cassava fermentation medium containing 12.5% (m / m) of total sugar to 550m 3 In the first-stage fermenter of the tank capacity, when the fermentation medium accounts for 75% of the volume of the fermenter, the ventilation, stirring and cooling systems are started to maintain the temperature of the material liquid in the fermenter at 35-37°C and the inoculation amount is 10%. Inject Aspergillus niger balls from the seed tank and maintain an air volume of 8.5 m 3 / m 3 h, pH2.9-4.5;

[0059] Press 31m 3 The flow rate of / h is continuously added to the primary fermentation tank with fermentation medium and aspergillus niger balls from the seed tank at a rate of 10%, according to 34.1m 3 The flow rate of / h flows out from the primary fermentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com