Shed film special for ginger

A greenhouse film and ginger technology, which is applied to climate change adaptation, horticulture, botanical equipment and methods, etc., can solve the problems of not producing plastic films in greenhouses, and achieve the effects of reducing field operation steps, increasing production efficiency, and increasing ginger yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is based on studying the light-requiring properties of ginger, aiming at the present situation that there is no special greenhouse film for ginger, and is developed through scientific and rational formula by adding suitable color masterbatch. The main technical indicators of the product are: the light transmittance is 60%-85%, the ratio of green light in the transmission spectrum is 5%-15% higher than that of ordinary greenhouse films, and the film thickness is 0.02-0.15mm.

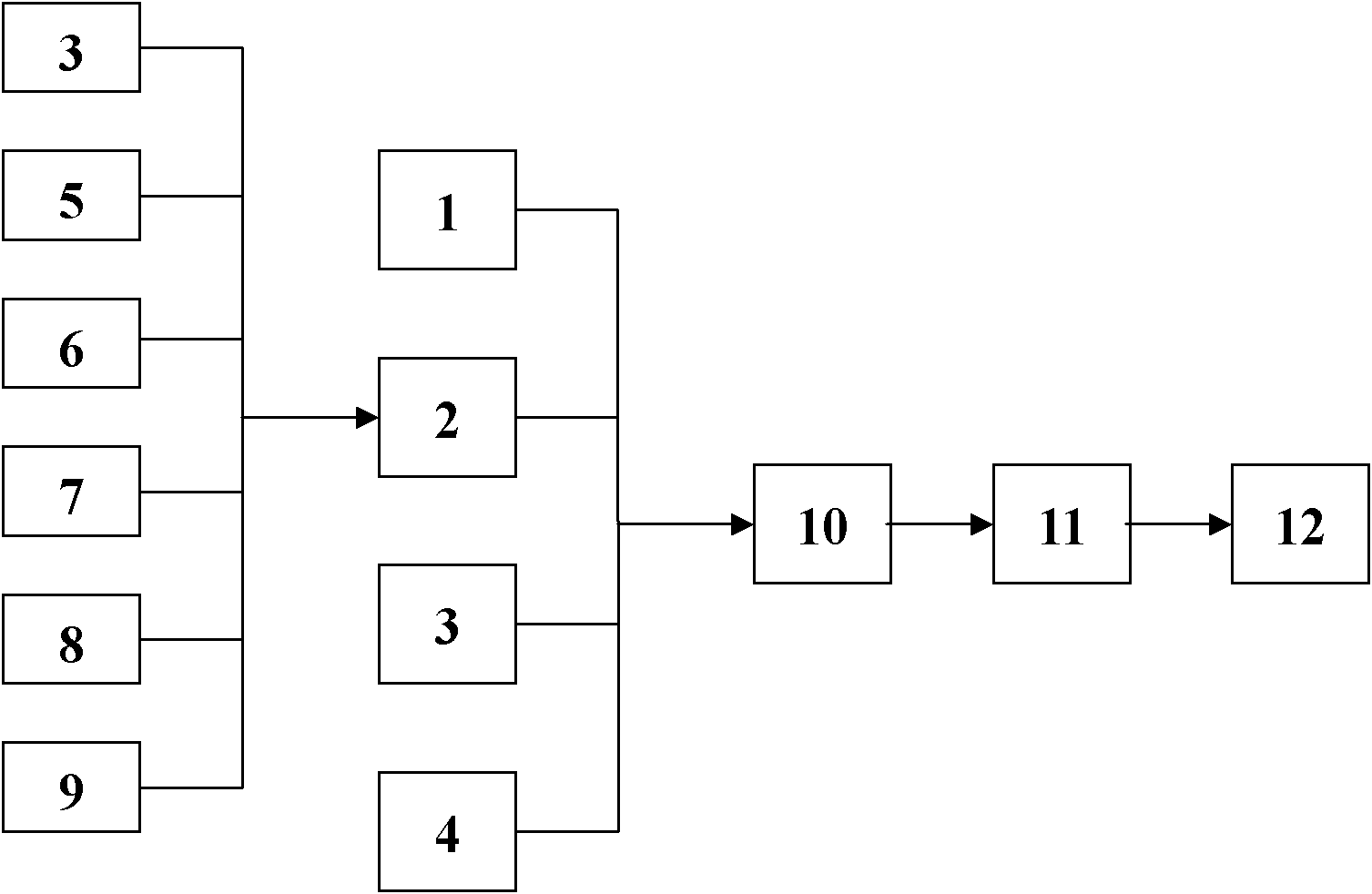

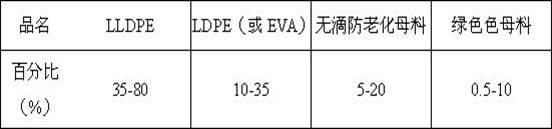

[0012] The specific processing procedures and requirements of this product are as follows: First, prepare the non-drip anti-aging masterbatch (2), the weight percentage of each component is: LLDPE powder 62.5%-82.5% (commercially available) (3), no drop agent LA- 2 10%-20% (5), insulation agent talc 5%-10% (6), antioxidant B215 0.5%-1.5% (7), light stabilizer 944 1%-3% (8) and light stabilizer 622 1%-3% (9). The above raw materials are fully mixed and uniformly heated, kneade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com