Method for preparing 2-aminoisonicotinic acid

A technology of isonicotinic acid and amino group, applied in the field of preparing 2-aminoisonicotinic acid, can solve problems such as the yield of only 5%, and achieve the effects of low price, mild reaction adjustment and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

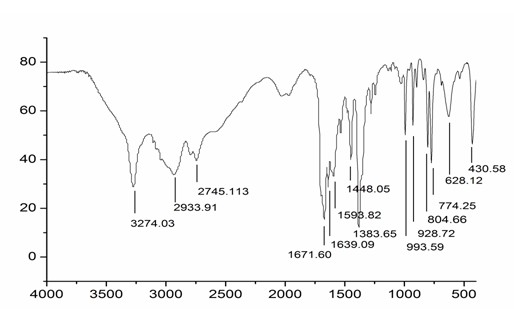

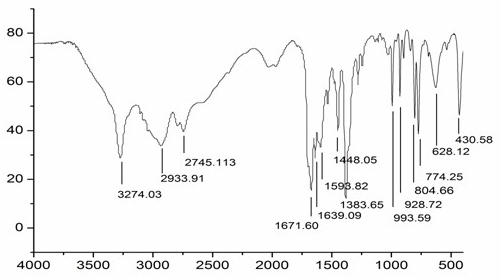

Image

Examples

Embodiment 1

[0016] (1) Put 5Kg of 2-amino-4-picoline into a 20L spherical reactor, then add 4.2Kg of glacial acetic acid (2-amino-4-picoline is insoluble) and drop 6.65Kg of acetyl chloride into the Reaction system, the reaction produces a large amount of white smoke, the dripping speed should not be too fast. The raw materials will dissolve during the dropwise addition of acetyl chloride, and after the dropwise addition, heat to reflux at 110° C. for 12 hours. After the reaction, stop heating and cool down in the reactor. When a certain amount of crystals are precipitated, put them in water (about 70°C) and continue to cool down to crystallize. Stir frequently during the crystallization process, otherwise they will stick together and suction filtration will be difficult. . After room temperature, filter with suction. The filtrate should be kept, and the unseparated crystals in it can be distilled under reduced pressure after the batch is completed, and the crystals can also be precipit...

Embodiment 2

[0019] (1) Put 5Kg of 2-amino-4-picoline into a 20L spherical reactor, then add 4.6Kg of glacial acetic acid (2-amino-4-picoline is insoluble) and drop 6.3Kg of acetyl chloride into the Reaction system, the reaction produces a large amount of white smoke, the dripping speed should not be too fast. The raw materials will dissolve during the dropwise addition of acetyl chloride, and after the dropwise addition, heat to reflux at 105°C for 13 hours. After the reaction, stop heating and cool down in the reactor. When a certain amount of crystals are precipitated, put them in water (about 70°C) and continue to cool down to crystallize. Stir frequently during the crystallization process, otherwise they will stick together and suction filtration will be difficult. . After room temperature, filter with suction. The filtrate should be kept, and the unseparated crystals in it can be distilled under reduced pressure after the batch is completed, and the crystals can also be precipitate...

Embodiment 3

[0022] (1) Put 5Kg of 2-amino-4-picoline into a 20L spherical reactor, then add 5Kg of glacial acetic acid (2-amino-4-picoline is insoluble) and drop 6.65Kg of acetyl chloride into the reaction while stirring system, the reaction produces a large amount of white smoke, and the dripping speed should not be too fast. The raw materials will dissolve during the dropwise addition of acetyl chloride, and after the dropwise addition, heat to reflux at 110° C. for 12 hours. After the reaction, stop heating and cool down in the reactor. When a certain amount of crystals are precipitated, put them in water (about 70°C) and continue to cool down to crystallize. Stir frequently during the crystallization process, otherwise they will stick together and suction filtration will be difficult. . After room temperature, filter with suction. The filtrate should be kept, and the unseparated crystals in it can be distilled under reduced pressure after the batch is completed, and the crystals can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com