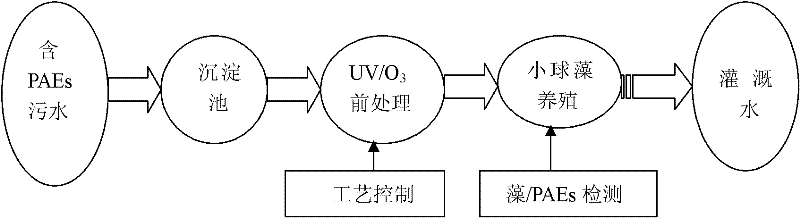

Method for removing phthalates out of water by utilizing UV (ultraviolet)/ozone/chlorella degradation composite process

A technology of phthalates and chlorella, applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of long time-consuming DMP and shorten the treatment time , save energy and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Start with 1mg.L -1 The phthalate-contaminated water was sampled and pre-tested for UV / ozone joint process, and the process parameters were determined to be: UV intensity 135μW.cm -2 , ozone flux 2.0mg.h -1 .L -1 And the treatment time for the removal rate to reach 90% is 30 minutes, so the ultraviolet intensity is 135μW.cm -2 , Ozone inflow rate 2.0mg.h -1 .L -1 The water body is pre-treated for 10 minutes; the pre-treated water is then injected into the 100m 2 The biological redegradation is carried out in the chlorella culture pond of the area, and the chlorella culture density is 1.0×10 7 ~1.0×10 8 ml -1 ; The content of phthalates in the detected water is 0.0074mg.L -1 , discharged into farmland as irrigation water. This process produces 120kg of algae per year, saves 8kW.h of energy compared with the pure UV / ozone process, and shortens the time by 20h compared with the pure biodegradation process.

Embodiment 2

[0031] Start with 2mg.L -1The phthalate-contaminated water was sampled and pre-tested for UV / ozone joint process, and the process parameters were determined to be: UV intensity 135μW.cm -2 , ozone flux 4.0mg.h -1 .L -1 And the treatment time for the removal rate to reach 90% is 30 minutes, so the ultraviolet intensity is 135μW.cm -2 , Ozone inflow 4.0mg.h -1 .L -1 The water body is pre-treated for 10 minutes; the treated water is then injected 100m 2 Bioredegradation is carried out in the chlorella culture pool of the area, and the chlorella culture density is 1.5×10 7 ~1.6×10 8 ml -1 ; The content of phthalates in the detected water was 0.0079mg.L -1 , discharged into farmland as irrigation water. This process produces 130kg of algae per year, saves 16kW.h of energy compared with the pure UV / ozone process, and shortens the time by 20h compared with the pure biodegradation process.

Embodiment 3

[0033] Start with 4mg.L -1 Sampling of phthalate-contaminated water and conduct a pre-test of UV / ozone joint process, and determine the process parameters: UV intensity 202.5μW.cm -2 , ozone flux 6.0mg.h -1 .L -1 And the treatment time for the removal rate to reach 90% is 30 minutes, so the ultraviolet intensity is 202.5μW.cm -2 , Ozone inflow 6.0mg.h -1 .L -1 The water body is pre-treated for 10 minutes (9-12 minutes, take 10 minutes); the treated water is injected into 100m 2 The biological re-degradation is carried out in the chlorella culture pool of the area, and the chlorella culture density is 1.6×10 7 ~1.8×10 8 ml -1 ; The content of phthalates in the detection water is 0.0075mg.L -1 , discharged into farmland as irrigation water. This process produces 130kg of algae per year, saves 30kW.h of energy compared with the pure UV / ozone process, and shortens the time by 21h compared with the pure biodegradation process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| UV radiation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com