Method for reducing curved conduit rail surface corrugation

A curve and wave grinding technology, applied in railway car body parts, railway vehicle shape measuring instruments, railway auxiliary equipment, etc., can solve the problems of inattentive curve design, single vehicle model, low resonance gain, etc. Maintenance workload and expenses, improving safety, and reducing the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

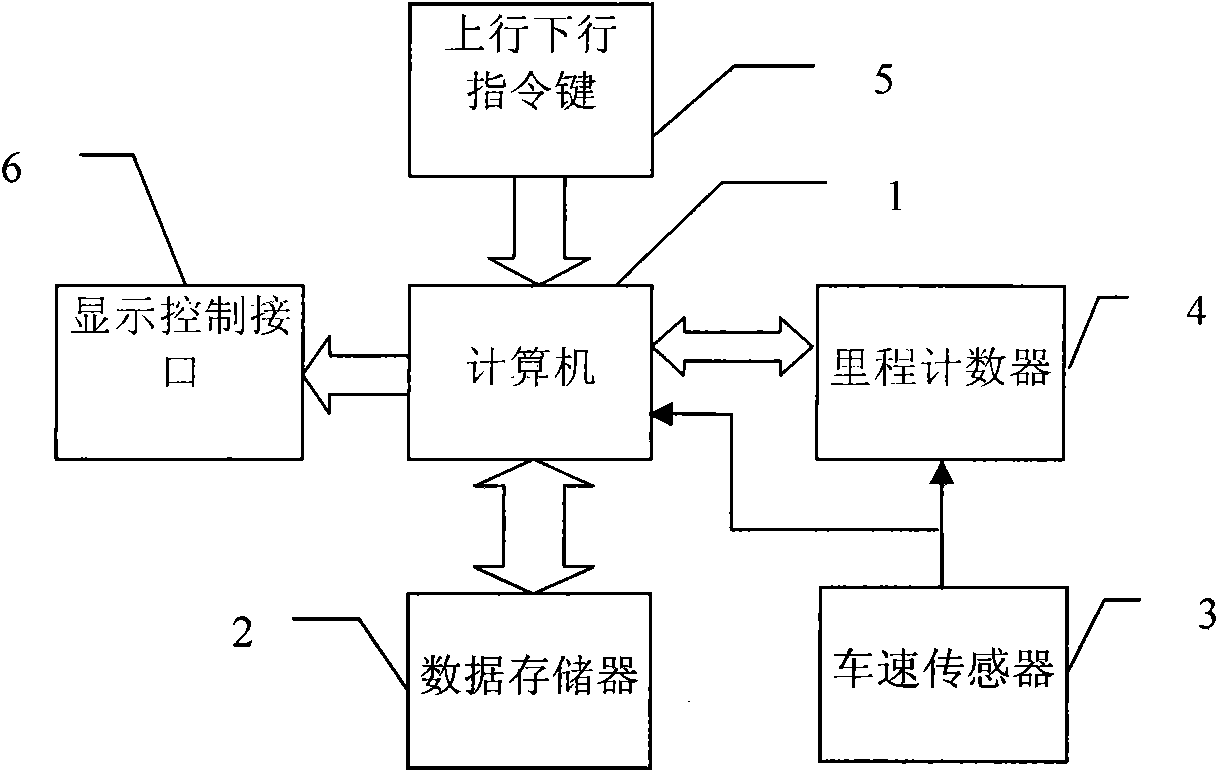

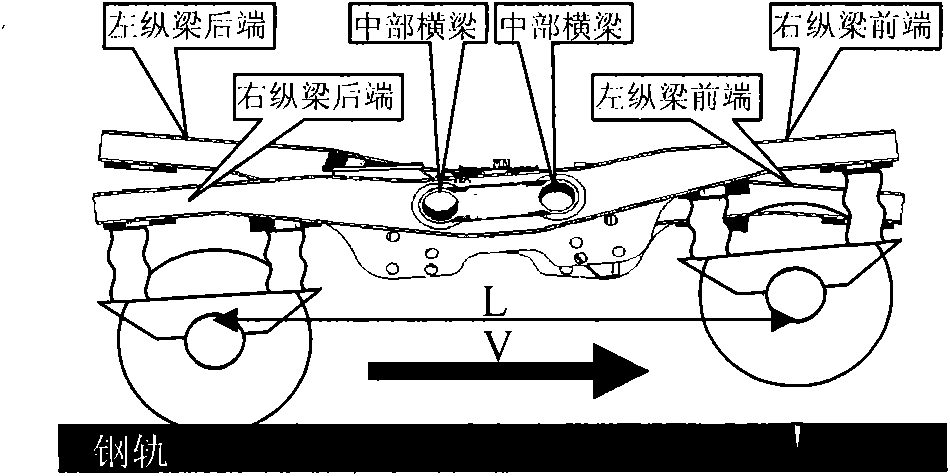

[0105] The present invention proposes a monitoring device for reducing curved track surface corrugation and a vehicle and track improvement method. The maximum mileage SZ of the line, the design vehicle speed V(n) of each curve, the vehicle wheelbase L, the diameter D[mm] of the wheel where the vehicle speed sensor is located, the number of pulses sent by the vehicle speed sensor when the wheel rotates one revolution m, bogie The data memory 2 and the computer 1 including the longitudinal beam resonance frequency F, the data memory 2 can be the memory in the computer 1, or an external memory, the two are connected by a data bus, and the computer can pass through its contained peripherals, Obtain the data of two kinds of storage and data memory, store it in the data memory through the data bus, and also read the required data from the data memory; it also contains a vehicle speed sensor 3 installed on the circumference of the wheel whose diameter is D, and each wheel After one ...

Embodiment 2

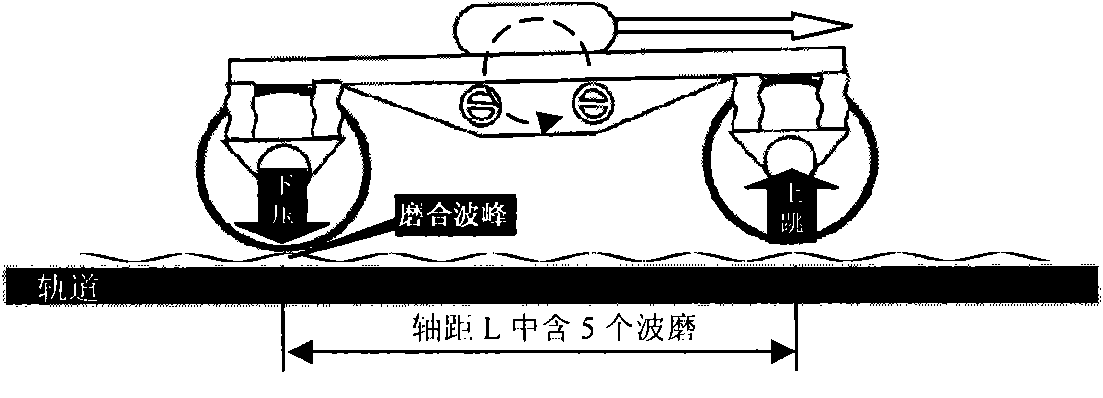

[0107] In the vehicle improvement technology, in order to reduce the amplification factor, amplitude, and generalized resonance time or fluctuation times of the longitudinal beam generalized resonance, the vibration damping of the longitudinal beam can be increased by increasing the vibration damping of the longitudinal beam from above the wheels at both ends of the vehicle's bogie longitudinal beam to the bottom of the car box. A damper that does not affect the rotation of the bogie relative to the carriage. as attached Image 6 .

[0108] Shock absorbers with similar effects can also use air springs and metal rubber springs. as attached Figure 7 .

[0109] Figure 8-10 It is the simulation diagram of track corrugation after changing the damping of the bogie longitudinal beam. After increasing the damping of the bogie longitudinal beam, the generalized resonance of the front and rear wheels gradually decreases, so that the corrugation also gradually decreases.

Embodiment 3

[0111] It is also possible to obtain the current frame resonance frequency data F of each car and each bogie through the relevant interface with the existing subway fault monitoring device, and calculate the new suggested vehicle speed VJ according to the value after the resonance frequency changes by more than 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com