A flame-retardant solid wood composite profile and its manufacturing method

A technology of composite profiles and manufacturing methods, which is applied in the manufacture of thin wood chips, impregnated wood, and tool manufacturing, can solve the problems of poor dimensional stability of flame-retardant profiles, poor service life of decay resistance, and prone to mildew and blue stains, etc., to achieve Accelerates the drying speed and heat treatment improvement speed, is not easy to be lost, and has the effect of high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Wood chip production steps: select the masson pine sawn timber, and cut it into 5.5mm thick masson pine wood chips by a frame saw.

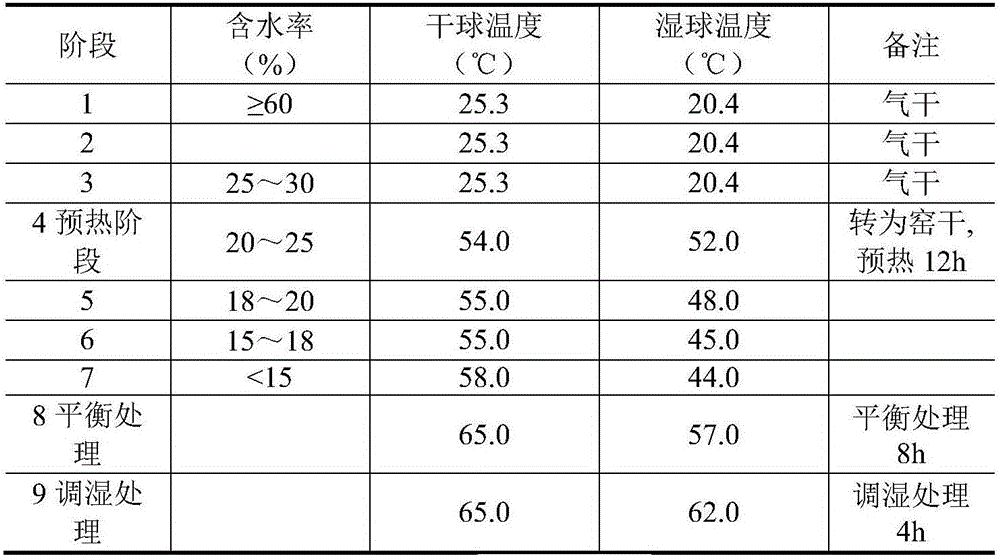

[0046] (2) The first stacking and drying step: stack 5 pieces of masson pine wood chips with a thickness of 5.5mm to form a stack, use trays with uniform specifications and aluminum alloy spacers, and the distance between the spacers and the end surface of the veneer is within 5cm when stacking , the distance between the bars is 20cm, and the bars are neatly formed in a straight line in the vertical direction. Cement blocks are pressed on the stacked veneer, and placed in the air-drying shed for air-drying first (the average temperature of day and night is 25.3 ° C, day and night The average wind speed is 2.1m / s, the season is September), and when the moisture content of the wood chips is reduced to about 25%, it is then moved to a drying kiln for kiln drying, so that the moisture content of the veneer is 10%. The combined drying proce...

Embodiment 2

[0059] (1) Wood chip production steps: select poplar sawn timber, and saw it into 4.5mm thick poplar wood chips by a multi-blade sawing machine.

[0060] (2) The first stacking and drying step: stack 2 pieces of poplar wood chips with a thickness of 4.5mm together to form a whole stack, use trays with uniform specifications and aluminum alloy spacers, and the distance between the spacers and the end surface of the veneer is 5cm when stacking Within 10cm, the spacing of the spacers is 10cm, and the spacers are neatly formed in a straight line in the vertical direction. Cement blocks are pressed on the stacked wood chips, and the poplar wood chips are dried by a kiln drying process to make the poplar wood chips dry. rate was reduced to 15%.

[0061] (3) Heat treatment improvement step: Send the dried wood chip pile directly into the heat treatment kiln with a forklift, close the heat treatment kiln door, open the heating and humidification valves at the same time, heat up the wo...

Embodiment 3

[0070] (1) Steps for making wood chips: select poplar sawn timber, and slice it into 1.2mm thick poplar wood chips by a slicer.

[0071] (2) The first stacking and drying step: stack 5 pieces of 1.2mm thick poplar wood chips together to form a whole stack, use trays with uniform specifications and aluminum alloy spacers, and the distance between the spacers and the end surface of the veneer is 5cm when stacking Within 10cm, the spacing of the spacers is 10cm, and the spacers are neatly formed in a straight line in the vertical direction. Cement blocks are pressed on the stacked wood chips, and the poplar wood chips are dried by a kiln drying process to make the poplar wood chips dry. rate was reduced to 15%.

[0072] (3) Heat treatment improvement steps: Send the dried wood chip pile directly into the heat treatment kiln with a forklift, close the heat treatment kiln door, open the heating and humidification valves at the same time, heat up the wood veneer directly to 190°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com