Automobile door hinge clamp

A door hinge and fixture technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of increasing the production cost of manufacturers, complicated procedures and cumbersome devices, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

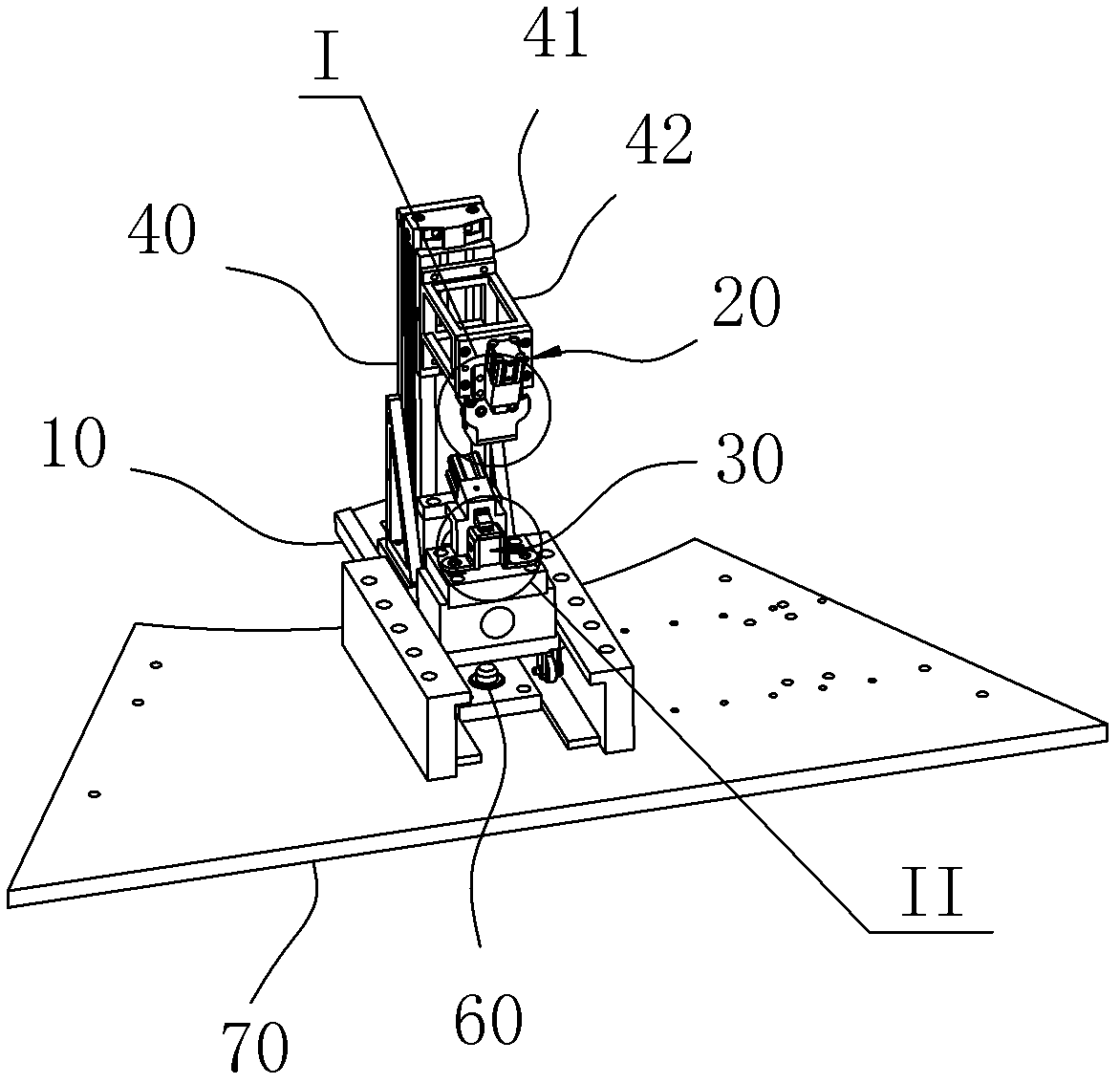

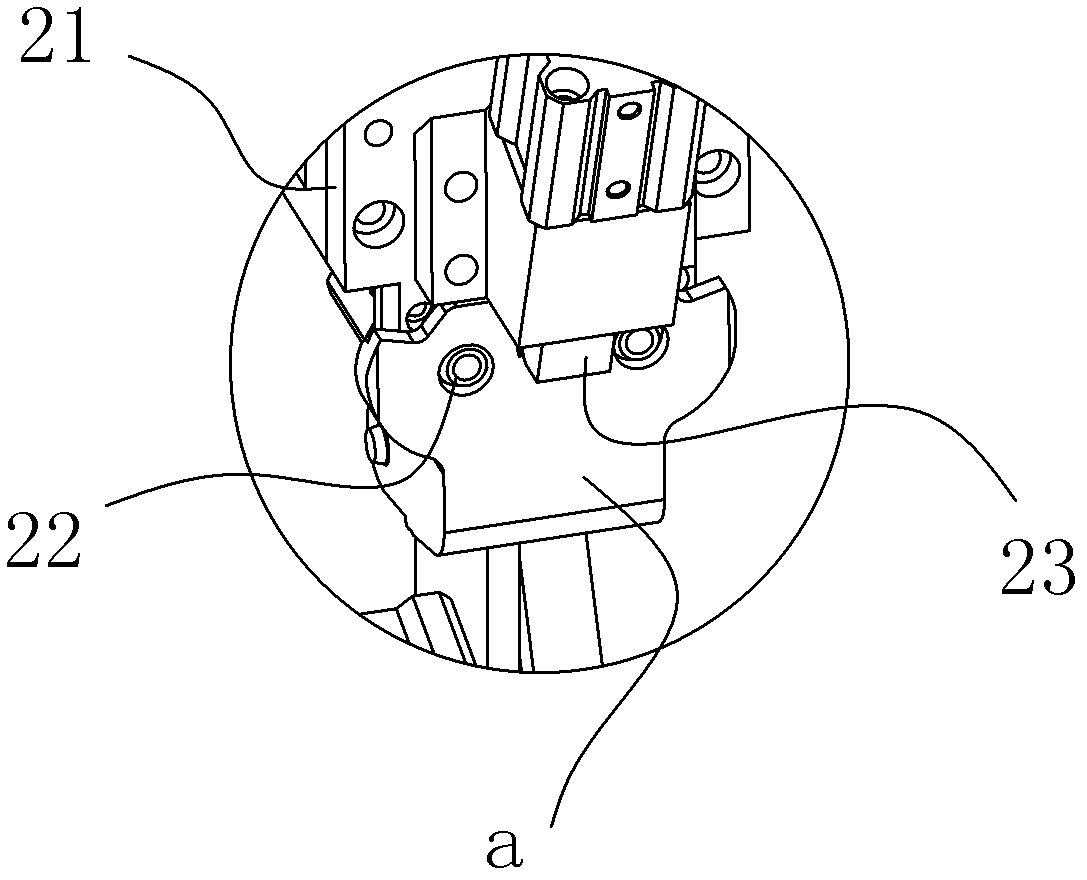

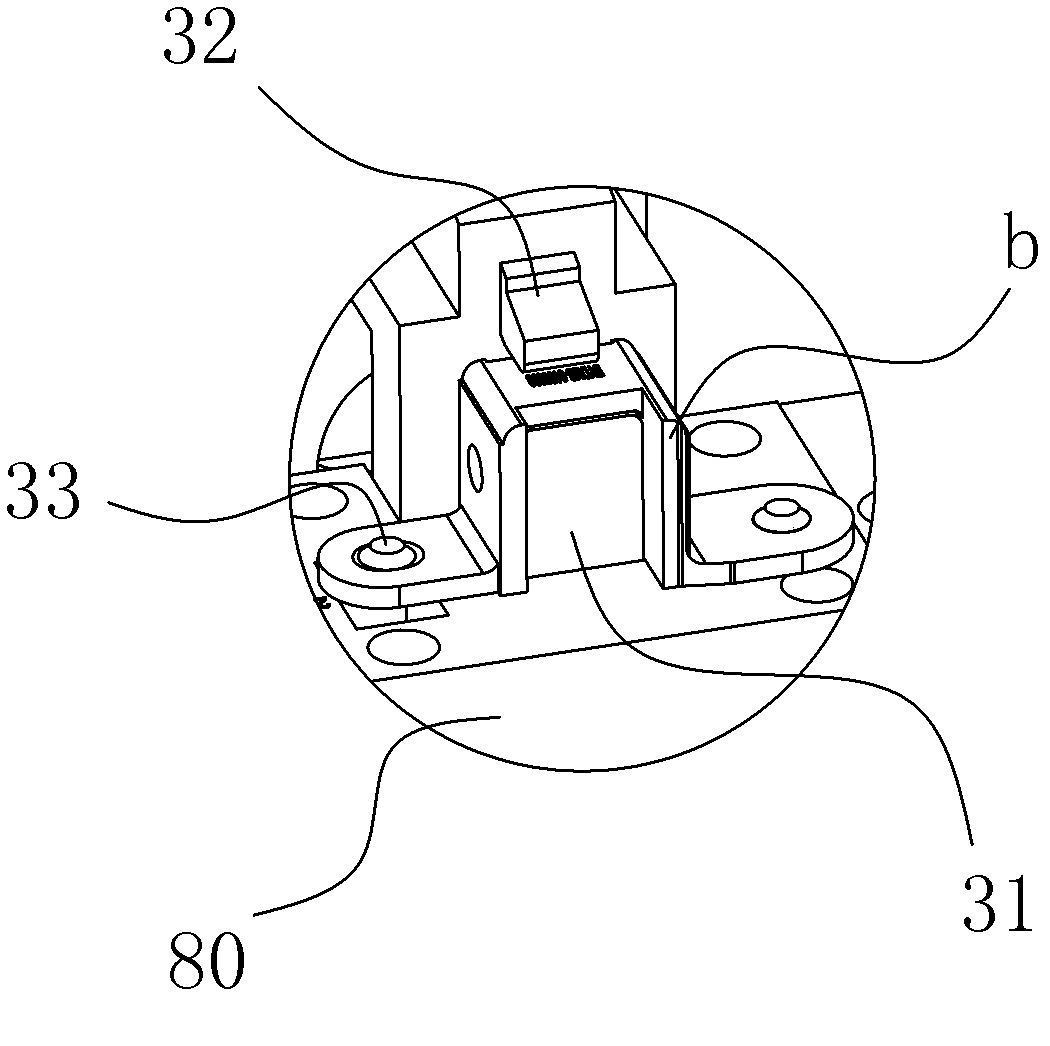

[0014] An automobile door hinge clamp, the clamp includes a base 10 and a clamping portion arranged on the base 10 for clamping the hinge, the clamping portion includes a first clamping portion 20 for clamping the main hinge And the second clamping part 30 for clamping the secondary hinge, the axes of the pin shaft holes of the two hinges clamped on the clamping part are parallel to each other, and the clamp has two position states, one of which is two clamps The holding parts are separated from each other and the corresponding hinge parts are installed separately. Another position state is that the two holding parts move relative to each other along the plane formed by the axes of the two parallel pin shaft holes, and finally guide the axes of the pin shaft holes of the two hinges to coincide and make Both of the above are in the correct assembly position, as in figure 1 and Figure 7-8 shown.

[0015] For ease of understanding, the structure of one of the assembly machines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com