Annular groove machining cutter tool used for vertical drilling machine

A technology for processing cutting tools and ring grooves, which is applied in the direction of manufacturing tools, metal processing equipment, milling cutters, etc., can solve the problems of inconsistent depth and dimension, long adjustment time, and difficult clamping of workpieces, etc., to achieve good size consistency and production The effect of improving efficiency and easy quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

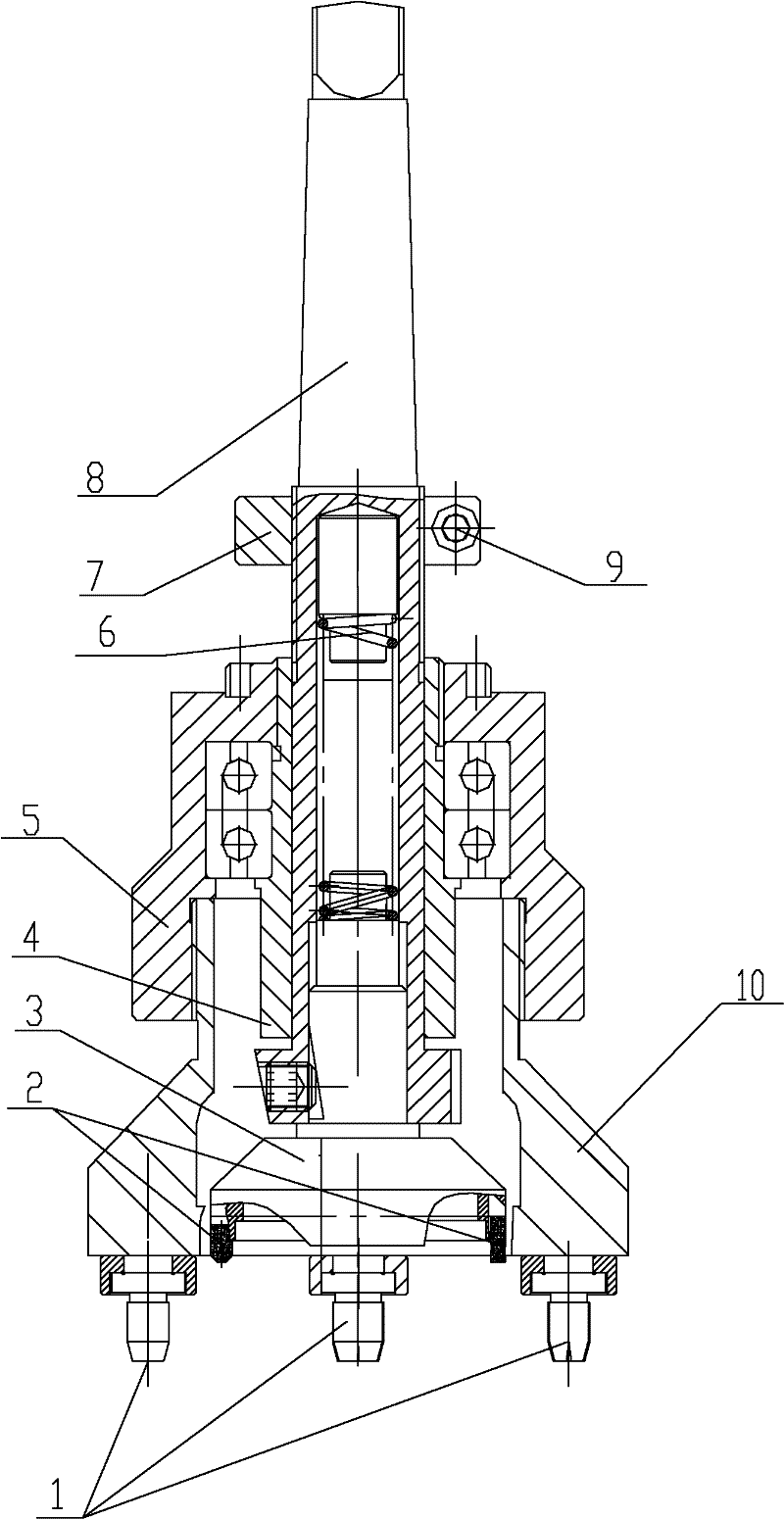

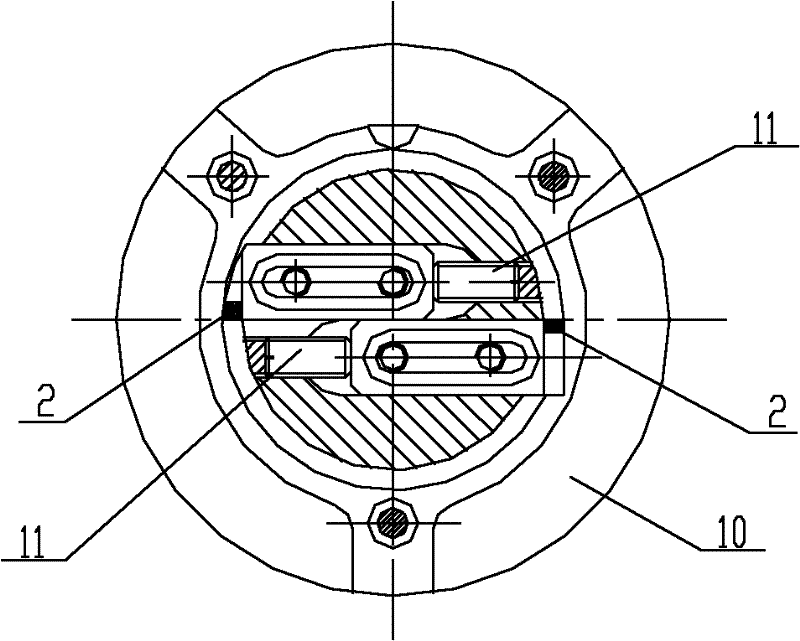

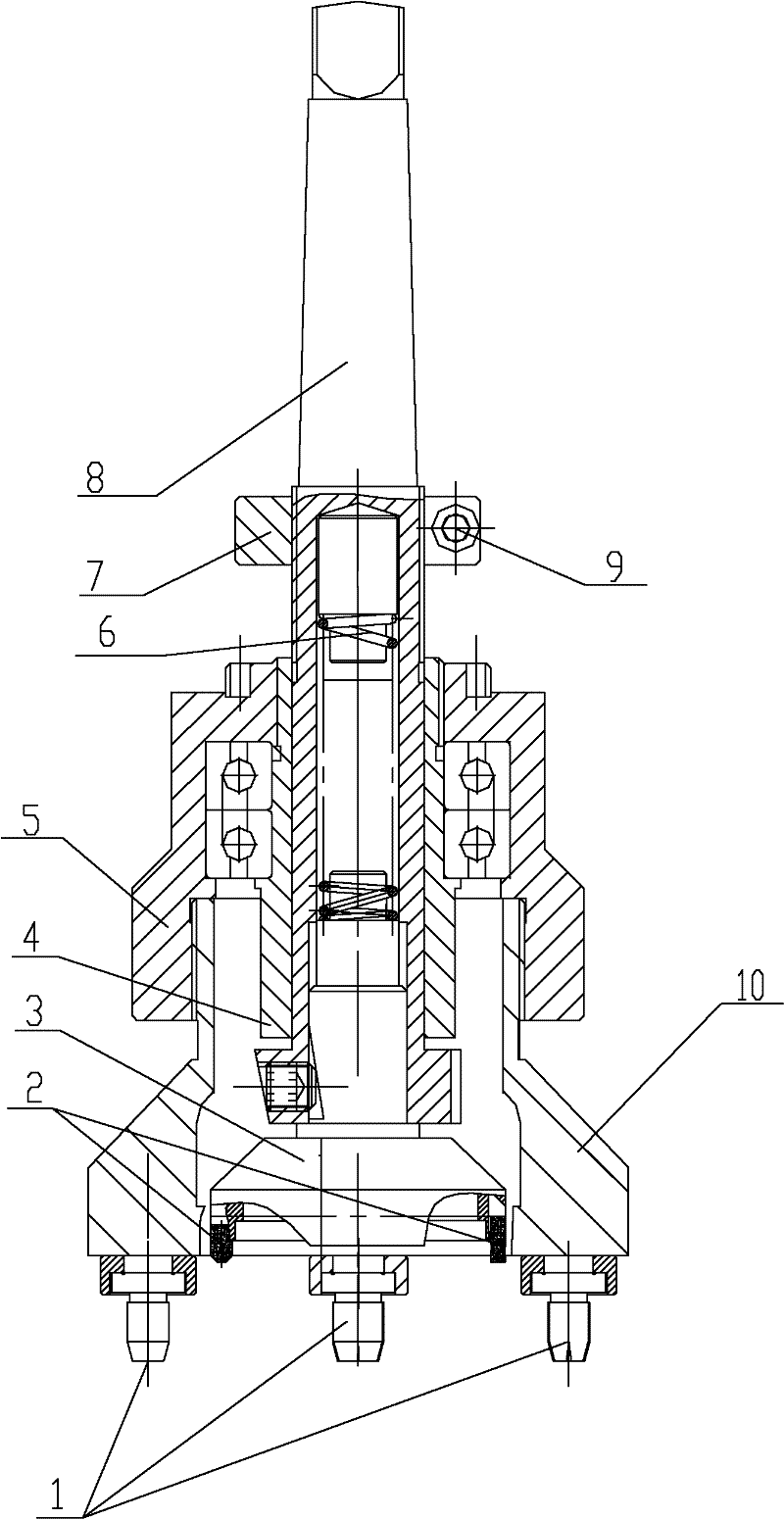

[0018] see Figure 1 ~ Figure 2 , a ring groove processing tool for vertical drilling, including a tool bar 8, the middle part of the tool bar 8 is threaded with a limit lock nut 7, and the lower part of the tool bar 8 is threaded with a mandrel sleeve 4, the The bottom of the cutter bar 8 is equipped with a cutter head 3, on which symmetrically arranged chamfering and grooving cutter heads 2 are arranged; the top of the cutter head 3 is provided with a compression spring installed in the center hole of the cutter bar 6. The outer circle of the mandrel sleeve 4 is supported by a bearing 5 , the bottom of the outer sleeve 5 is fixedly connected with a three-jaw positioning sleeve 10 , and the bottom of the three-jaw positioning sleeve 10 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com