Robot for automatic sorting of eyeglass quality

A technology of automatic sorting and robotics, applied in the right field, can solve the problems of no quality standards in the lens industry, and achieve the effect of improving the application level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

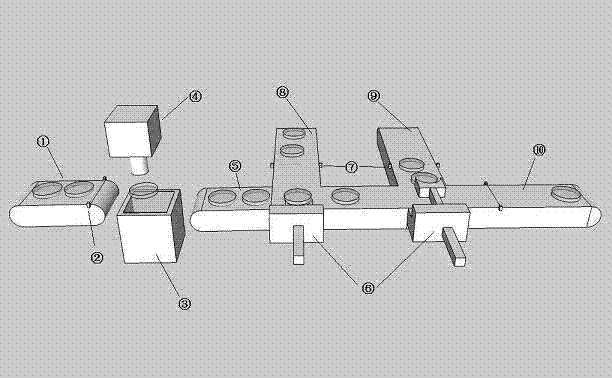

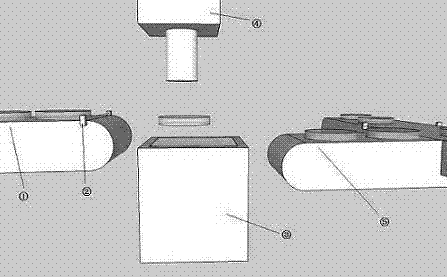

[0016] figure 1 ①⑤⑧⑨⑩ in it is the conveying subsystem, which is responsible for conveying one piece at a time to the moving direction of the assembly line according to the specified path, among which ⑧⑨⑩ is the conveying lane part of each quality level;

[0017] figure 1 ② in it is the trigger subsystem, which is responsible for sensing the lenses in the inspection area and driving ④ to work in time

[0018] figure 1 ③ in it is the lighting subsystem, which is responsible for emitting a uniform and bright LED light source from the bottom of the lens to illuminate the entire lens for clear imaging of ④ in order to obtain the image information of the lens more clearly when the lens reaches the top of the inspection area as a background light source;

[0019] figure 1 ④ in the imaging subsystem is the full digital industrial camera part, which is responsible for fast, complete and clear exposure, converting the image capture target into an image signal and storing it for cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com