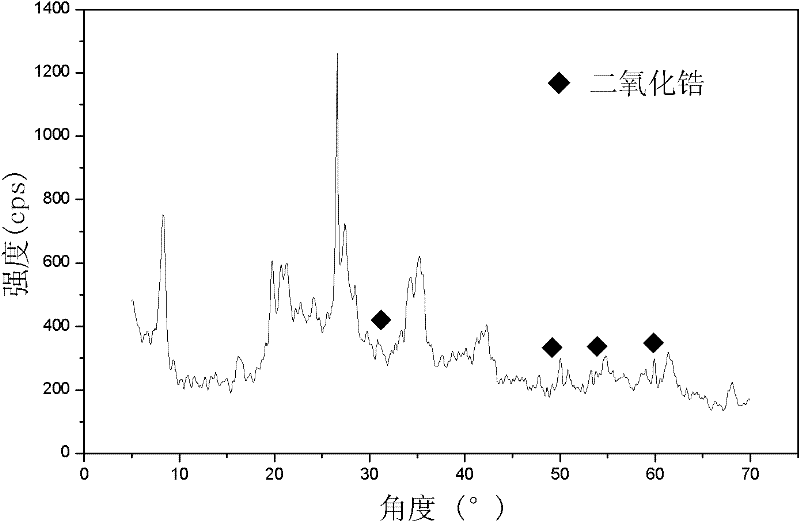

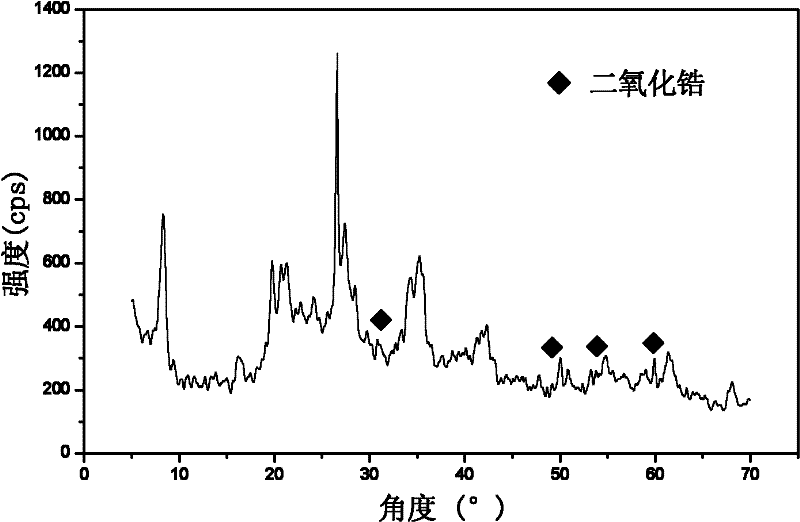

Preparation method of attapulgite/zirconia composite defluorinating material

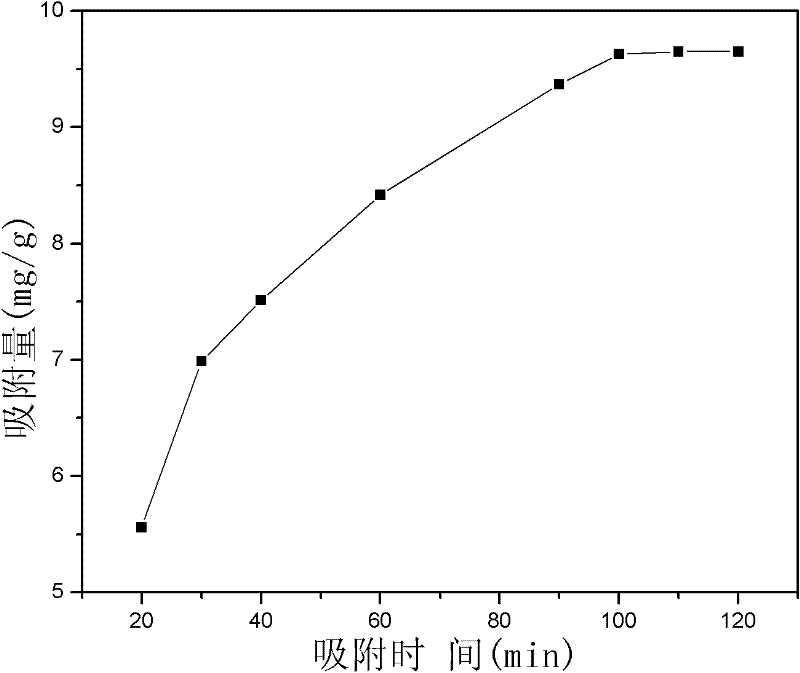

A technology of zirconia and fluorine materials, applied in chemical instruments and methods, other chemical processes, adsorbed water/sewage treatment, etc., can solve the problem of attapulgite-based defluorination adsorbents with small adsorption capacity, narrow water treatment range, and pH changes. Sensitivity and other issues, to achieve the effects of excellent ion exchange performance, fast adsorption rate and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Selection of raw materials: Weigh 16g of NaOH, add deionized water, and prepare 0.4mol / L NaOH solution for later use; Weigh 13.3g of Al 2 (SO 4 ) 3 ·18H 2 O, add deionized water to make 0.05mol / L Al 2 (SO 4 ) 3 The solution is ready for use; according to the mass ratio of 3:6, weigh 3g of ZrO(NO 3 ) 2 ·2H 2 O and 6g of sodiumized attapulgite for later use; 3g of ZrO(NO 3 ) 2 ·2H 2 O was added to a beaker containing 200 mL of deionized water, after ultrasonic dispersion for 10 minutes, aging at a constant temperature of 60°C for 12 hours, and then standing at room temperature for 15 hours to obtain ZrO(NO 3 ) 2 Solution, set aside.

[0027] 2) Weigh 6 g of the sodiumized attapulgite, add deionized water to prepare a 5 wt% suspension, and stir vigorously at 60° C. for 10 minutes to obtain an attapulgite suspension for use.

[0028] 3) The ZrO(NO 3 ) 2 After the solution was added dropwise to the attapulgite suspension, stirring was continued for 2 hours, and then the pH was a...

Embodiment 2

[0036] 1) Selection of raw materials: Weigh 16g of NaOH, add deionized water to prepare 0.4mol / L NaOH solution for later use; Weigh 13.3g of Al 2 (SO 4 ) 3 ·18H 2 O, add deionized water to make 0.05mol / L Al 2 (SO 4 ) 3 The solution is ready for use; according to the mass ratio of 5:6, weigh 5g of ZrO(NO 3 ) 2 ·2H 2 O and 6g of sodiumized attapulgite for use; add 5g of ZrO(NO 3 ) 2 ·2H 2 O was added to a beaker containing 200 mL of deionized water, ultrasonically dispersed for 10 minutes, then aged for 12 hours at a constant temperature of 70°C, and then left standing at room temperature for 15 hours to obtain ZrO(NO 3 ) 2 Solution, set aside.

[0037] 2) Add 6 g of sodiumized attapulgite to 5wt% suspension by adding deionized water, and stir vigorously at 70°C for 10 minutes to obtain an attapulgite suspension for use.

[0038] 3) The ZrO(NO 3 ) 2 After the solution was added dropwise to the attapulgite suspension, stirring was continued for 2 hours, and then the pH was adjusted to 5...

Embodiment 3

[0042] 1) Selection of raw materials: Weigh 16g of NaOH, add deionized water, and prepare 0.4mol / L NaOH solution for later use; Weigh 13.3g of Al 2 (SO 4 ) 3 ·18H 2 O, add deionized water to make 0.05mol / L Al 2 (SO 4 ) 3 The solution is ready for use; according to the mass ratio of 3:6, weigh 3g of ZrO(NO 3 ) 2 ·2H 2 O and 6g of sodiumized attapulgite for later use; 3g of ZrO(NO 3 ) 2 ·2H 2 O was added to a beaker containing 200 mL of deionized water, ultrasonically dispersed for 10 minutes, then aged for 12 hours at a constant temperature of 65 ℃, and then allowed to stand at room temperature for 15 hours to obtain ZrO(NO 3 ) 2 Solution, set aside.

[0043] 2) Add 6 g of the sodiumized attapulgite to a 5 wt% suspension by adding deionized water, and stir vigorously at 65° C. for 10 minutes to obtain an attapulgite suspension for use.

[0044] 3) The ZrO(NO 3 ) 2 After the solution was added dropwise to the attapulgite suspension, stirring was continued for 2 hours, and then the pH w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com