Apparatus for treating and/or coating surface of substrate component

A substrate component and surface treatment technology, which is applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of insufficient number of substrates or substrate components, failure to comply with supply time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

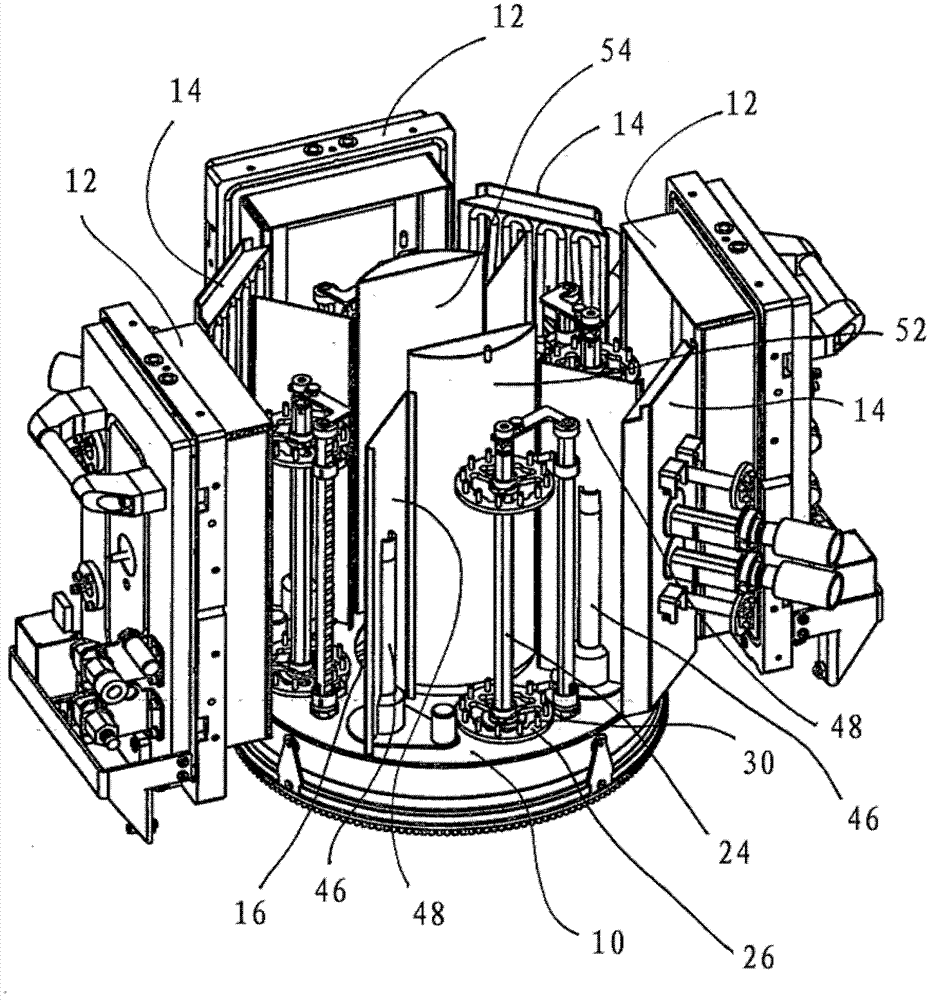

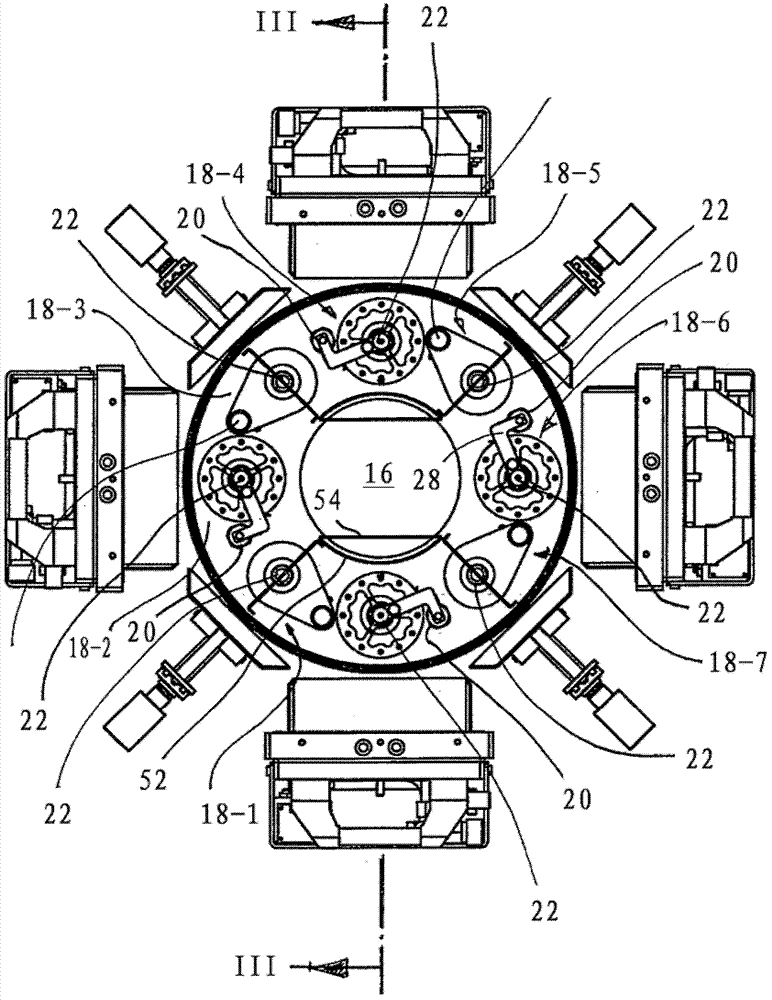

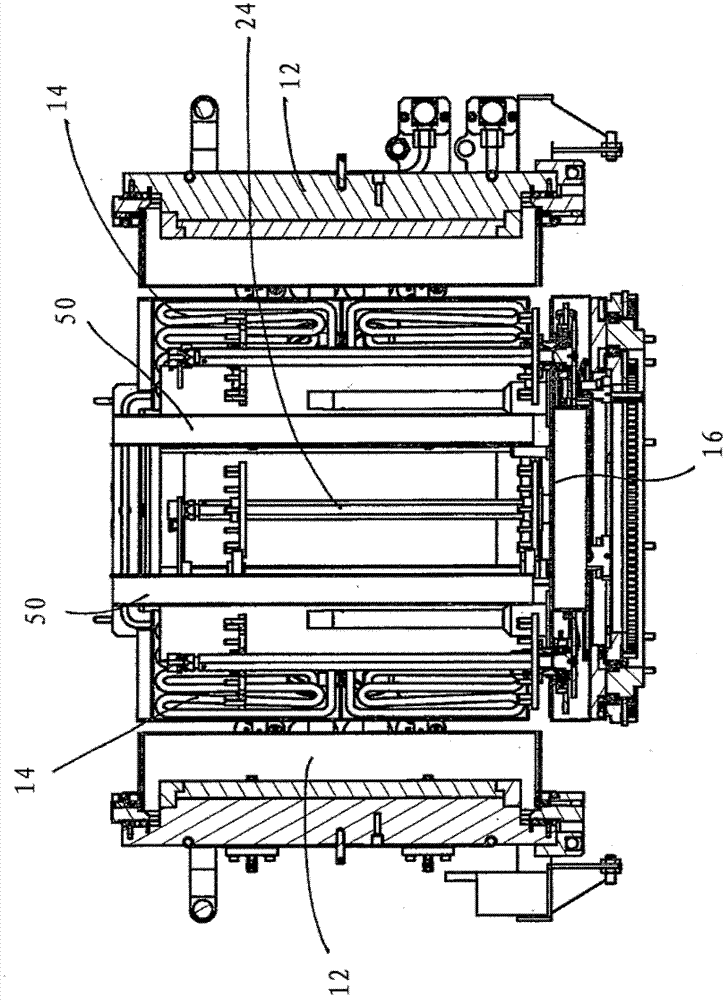

[0028] These figures schematically show the components accommodated in the interior of a process chamber (not shown in detail) of a coating system, which are required for the coating of substrate components according to the PVD method or according to the reactive PVD method. of. In other words, the configuration groups shown in these figures are arranged in a coating or vacuum chamber that can be evacuated and that is preferably equipped with various gas connections. Vacuum chambers of this type are known, so that a precise description of the chamber can be omitted here. The coating plant to be described in more detail below is characterized by the possibility of being equipped with an evacuable deposition or treatment chamber in order to significantly increase the economical efficiency of operating such a plant and to minimize the process time of the plant due to the improved flexibility.

[0029] A modular design of the coating plant is chosen for this purpose. Around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com