Method for analyzing nitrous oxide, methane and carbon dioxide in atmosphere by injecting sample once

A technology of nitrous oxide and carbon dioxide, which is applied in the field of carbon dioxide and one-shot analysis of nitrous oxide and methane in the atmosphere. It can solve the problems of data accuracy error and prolong the sample measurement period, so as to improve the data accuracy, shorten the sample measurement period, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

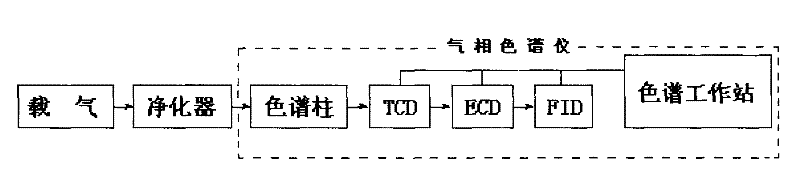

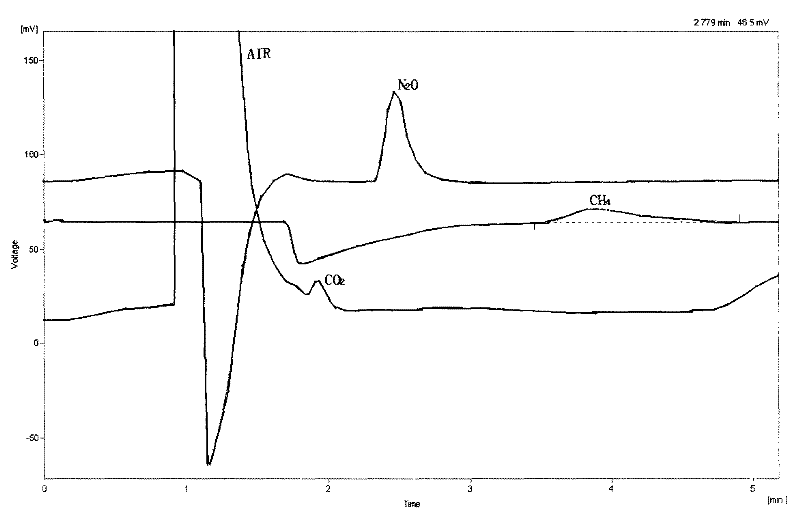

[0025] The method of embodiment 1 one-time sampling analysis nitrous oxide, methane, carbon dioxide in the atmosphere, at first the purity is less than 10 -5 % carrier gas - He passes through the purifier at an output pressure of 0.20Mpa, so that the purity of the purified carrier gas is less than 10 -6 %; then pass the purified carrier gas into the chromatographic column of the gas chromatograph with the flow rate of 25ml / min at a temperature of 25°C, after adsorption and desorption at a temperature of 25°C The nitrous oxide, methane and carbon dioxide in the sample to be tested enter the thermal conductivity cell detector (TCD), electron capture detector (ECD), and hydrogen flame ionization detector (FID) in sequence, and are detected at a temperature of 90°C ; Finally, the data obtained by thermal conductivity cell detector (TCD), electron capture detector (ECD) and hydrogen flame ionization detector (FID) are input to the chromatographic workstation in the gas chromatograp...

Embodiment 2

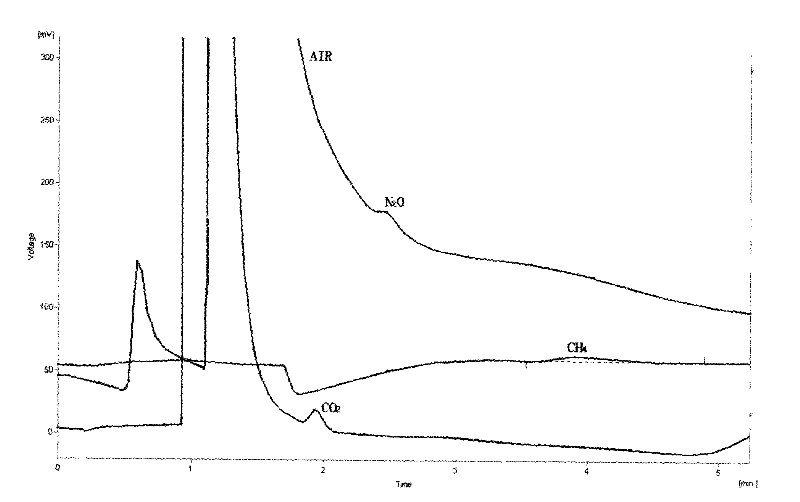

[0028] The method of embodiment 2 one-time sampling analysis nitrous oxide, methane, carbon dioxide in the atmosphere, at first the purity is less than 10 -5 % carrier gas—Ne passes through the purifier at an output pressure of 0.60Mpa, so that the purity of the purified carrier gas is less than 10 -7 %; then pass the purified carrier gas into the chromatographic column in the gas chromatograph where the sample to be tested has been placed at a flow rate of 195ml / min at a temperature of 65°C, and after adsorption and desorption at a temperature of 250°C , the nitrous oxide, methane and carbon dioxide in the sample to be tested enter the TCD, ECD, and FID in turn, and are detected at a temperature of 350°C; finally, the data obtained by the TCD, ECD, and FID are simultaneously input to the chromatographic workstation in the gas chromatograph , the chromatogram of the analysis result can be obtained.

[0029] Among them: the chromatographic column refers to a stainless steel tu...

Embodiment 3

[0031] The method of embodiment 3 one-time sampling analysis nitrous oxide, methane, carbon dioxide in the atmosphere, at first the purity is less than 10 -5 % of carrier gas——Ar passes through the purifier at an output pressure of 0.40Mpa, so that the purity of the purified carrier gas is less than 10 -6 %; then pass the purified carrier gas into the chromatographic column of the gas chromatograph where the sample to be tested has been placed at a temperature of 45°C at a flow rate of 110ml / min, and after adsorption and desorption at a temperature of 150°C , the nitrous oxide, methane and carbon dioxide in the sample to be tested enter the TCD, ECD, and FID in turn, and are detected at a temperature of 220°C; finally, the data obtained by the TCD, ECD, and FID are simultaneously input to the chromatographic workstation in the gas chromatograph , the chromatogram of the analysis result can be obtained.

[0032] Among them: the chromatographic column refers to a stainless stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com